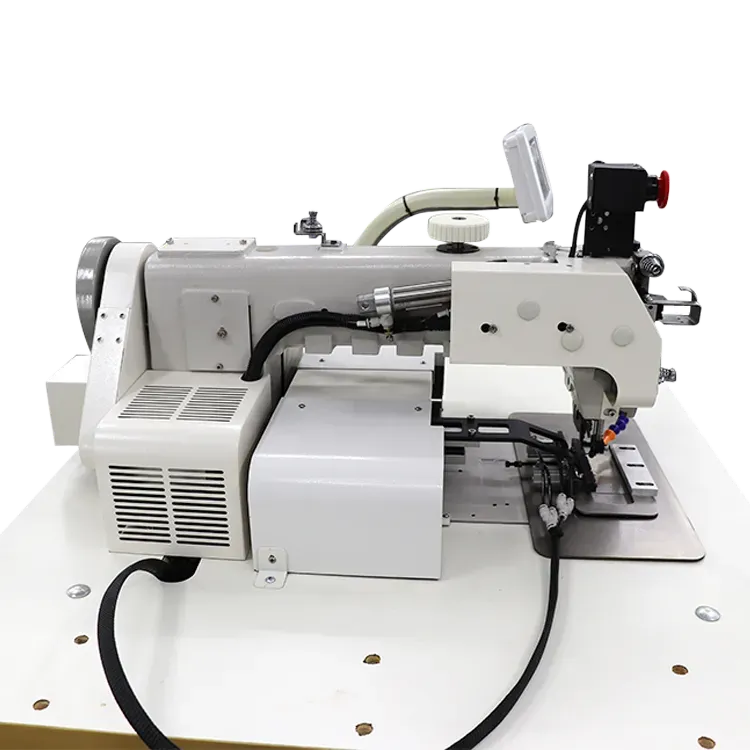

bulk bag sewing machine

The Importance of Bulk Bag Sewing Machines in Modern Manufacturing

In today's fast-paced industrial environment, efficiency and precision are paramount. This is especially true in sectors where bulk bags, also known as FIBC (Flexible Intermediate Bulk Containers), are used for packaging and transporting a wide range of materials, from agricultural products to construction aggregates. To meet the growing demand for these versatile containers, bulk bag sewing machines have become an indispensable tool in modern manufacturing.

Bulk bag sewing machines are specifically designed to sew large bags made from woven polypropylene or similar materials. Unlike traditional sewing machines, these specialized machines are built to handle heavier fabrics and thicker seams, making them ideal for the construction of bulk bags that need to withstand substantial weight and environmental conditions. One of the key advantages of using bulk bag sewing machines is their ability to produce bags at a high speed, significantly boosting production efficiency. In an era where time is money, the rapid output of these machines can lead to substantial cost savings for manufacturers.

Moreover, bulk bag sewing machines are engineered for precision

. The construction of bulk bags requires seams to be reinforced to prevent leaks and ensure the integrity of the contents during transport. These machines utilize various stitching techniques, such as lock stitching and chain stitching, which enhance the strength of the seams. By leveraging advanced technology, such as electronic controls and programmable settings, manufacturers can achieve consistent quality across large production runs, minimizing the risk of defects and ensuring compliance with industry standards.bulk bag sewing machine

Another significant advantage of bulk bag sewing machines is their adaptability. Many models come equipped with adjustable settings to accommodate different bag sizes and materials, making them versatile enough to handle a wide range of applications. This flexibility is crucial for manufacturers who may need to switch between different products or respond to changing customer demands. Additionally, some machines can be outfitted with various attachments, enabling them to perform tasks such as adding labels or handles to bulk bags, further streamlining the production process.

As sustainability becomes increasingly important in manufacturing, bulk bag sewing machines also play a role in promoting eco-friendly practices. FIBC bags are reusable and recyclable, making them a more sustainable option compared to single-use packaging solutions. By investing in efficient sewing machines, manufacturers can produce high-quality reusable bags that contribute to reducing waste and conserving resources.

In conclusion, bulk bag sewing machines are a vital asset in the modern manufacturing landscape. With their ability to enhance production speeds, ensure precision and quality, and adapt to various needs, these machines are key to meeting the growing demand for bulk packaging solutions. As industries continue to focus on efficiency and sustainability, the role of bulk bag sewing machines is expected to expand, driving innovation and progress in the packaging sector. For manufacturers looking to stay competitive, investing in advanced bulk bag sewing technology is not just beneficial but essential for long-term success.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025