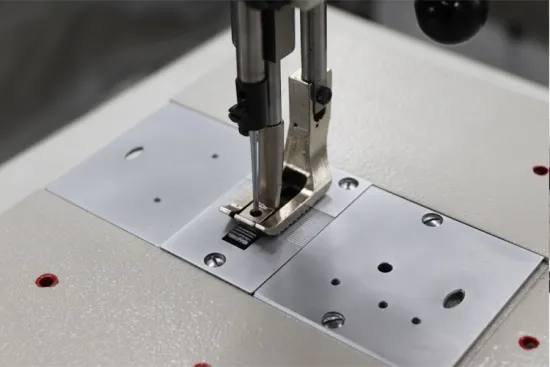

2 needle chain stitch machine

Understanding the 2% Needle Chain Stitch Machine A Revolution in Textile Manufacturing

The textile industry has seen numerous advancements over the years, and one of the most significant innovations is the introduction of the 2% needle chain stitch machine. This sophisticated piece of equipment has transformed the way fabrics are stitched, catering to the growing demands for efficiency, versatility, and precision in garment manufacturing.

What is a 2% Needle Chain Stitch Machine?

The 2% needle chain stitch machine is a specialized sewing machine designed for high-speed stitching of various types of fabric. As the name suggests, this machine typically utilizes two needles to create a chain stitch, which is known for its durability and flexibility. The 2% refers to the unique mechanism of the machine, which allows for enhanced performance, offering a significant improvement over traditional sewing machines.

Advantages of the 2% Needle Chain Stitch Machine

One of the primary advantages of the 2% needle chain stitch machine is its efficiency. With the capacity to sew at high speeds while maintaining quality, manufacturers can significantly increase production rates. This is particularly critical in an industry where time is money. The machine’s design minimizes downtime, ensuring that processes remain seamless.

Another key benefit is the enhanced durability of the chain stitch itself. The overlapping loops created by the two needles provide stronger seams compared to standard lock stitches, making it ideal for heavy fabrics typically used in workwear, sportswear, and denim. This attribute not only extends the lifespan of the garment but also reduces the likelihood of unraveling, which is a common issue in lower-quality stitching.

Additionally, the 2% needle machine offers remarkable versatility. It can be used on a variety of fabrics, ranging from delicate textiles to heavier materials. This adaptability allows manufacturers to diversify their product lines without the need for multiple sewing machines, thereby saving space and cost.

2 needle chain stitch machine

The Technology Behind the Machine

The technology used in the 2% needle chain stitch machine is state-of-the-art. It incorporates computerized systems that enhance precision and facilitate easier adjustments to stitch settings. This allows operators to switch between different types of stitches and fabric thickness effortlessly. Moreover, the machine often features automatic threading and tension control, reducing the need for manual intervention and minimizing the risk of errors.

Innovations like these not only improve the quality of the finished product but also make the work experience more user-friendly for the operators. With a focus on ergonomics, some models prioritize comfort and accessibility, which helps reduce fatigue during long production runs.

Challenges and Considerations

Despite its numerous advantages, the 2% needle chain stitch machine also presents some challenges. The initial investment can be substantial, which may deter smaller businesses from adopting this advanced technology. Additionally, operators require specific training to fully utilize its capabilities, which involves time and resources.

Another consideration is maintenance. While the machine is designed for robust performance, regular upkeep is necessary to ensure that it operates smoothly. Neglecting maintenance can lead to breakdowns, causing interruptions in production.

Conclusion

In conclusion, the 2% needle chain stitch machine stands at the forefront of textile manufacturing technology. Its combination of speed, strength, and versatility makes it an invaluable asset for businesses looking to enhance their production capabilities. Although the initial investment and training requirements are notable, the long-term benefits of improved efficiency and garment quality make it a worthwhile consideration for manufacturers aiming to remain competitive in the ever-evolving fashion industry. As technology continues to advance, the future of textile manufacturing looks promising, with machines like the 2% needle chain stitch machine leading the way.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025