2月 . 16, 2025 07:08

Back to list

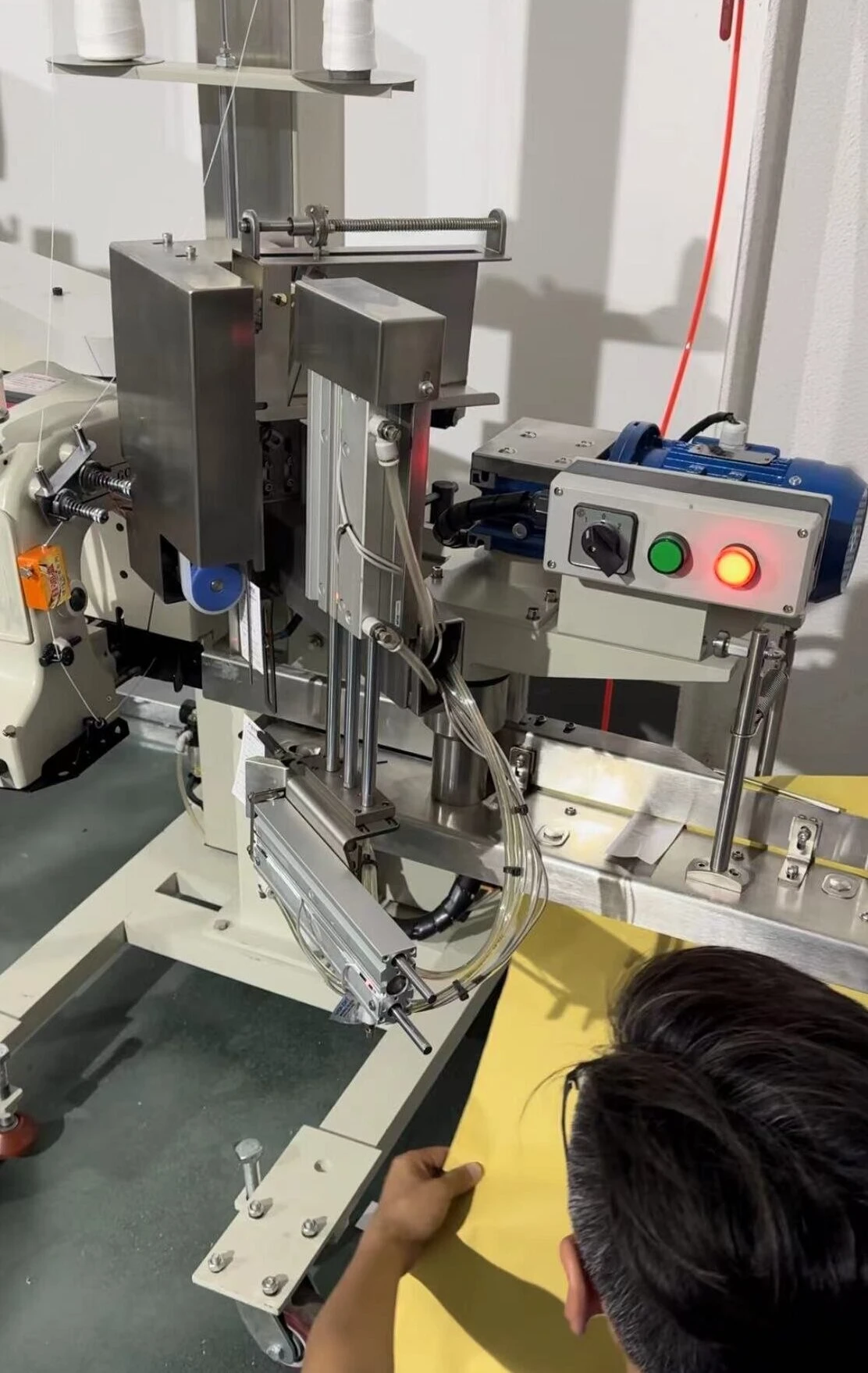

chain stitch sewing machine

The art of sewing thick material presents unique challenges and intricacies that necessitate both experience and expertise. When dealing with such robust fabrics, it's crucial to equip oneself with the right tools and techniques to ensure not only the project's success but also the longevity and durability of the end product.

For layers of thick material, utilizing walking foot attachments can be particularly beneficial. These attachments are specifically designed to evenly feed multiple layers through the machine, preventing the fabric from shifting and ensuring consistent stitch quality. Furthermore, the use of clips instead of pins can avoid unnecessary holes or distortions in thick materials. Another professional tip is to employ a fabric lubricant sparingly. Products like Sewer’s Aid can be applied to the needle to facilitate smoother penetration through thick fabrics, significantly reducing friction and the likelihood of needle breakage. When working on details such as hems or seams, pressing is crucial, but it can be tricky with thick materials. A heavy-duty steam iron or a tailor’s clapper can help set seams and hems effectively, giving your project a clean and professional finish. The key is to press firmly but without dragging the iron, to avoid undesired stretching or distortion. Safety should never be compromised. Thick materials often mean handling heavy equipment and sharp tools, so using protective gear such as gloves and ensuring a well-lit work environment can prevent accidents. In conclusion, sewing thick materials demands a blend of the right equipment, precise techniques, and an understanding of the material's properties. An informed approach not only helps in overcoming the challenges associated with sewing these robust fabrics but also guarantees that the finished product is of high quality and professional caliber. Whether you're creating a durable canvas bag or hemming a pair of jeans, the satisfaction of mastering such challenging materials is a reward in itself, reflected in the resilience and beauty of your handcrafted creations.

For layers of thick material, utilizing walking foot attachments can be particularly beneficial. These attachments are specifically designed to evenly feed multiple layers through the machine, preventing the fabric from shifting and ensuring consistent stitch quality. Furthermore, the use of clips instead of pins can avoid unnecessary holes or distortions in thick materials. Another professional tip is to employ a fabric lubricant sparingly. Products like Sewer’s Aid can be applied to the needle to facilitate smoother penetration through thick fabrics, significantly reducing friction and the likelihood of needle breakage. When working on details such as hems or seams, pressing is crucial, but it can be tricky with thick materials. A heavy-duty steam iron or a tailor’s clapper can help set seams and hems effectively, giving your project a clean and professional finish. The key is to press firmly but without dragging the iron, to avoid undesired stretching or distortion. Safety should never be compromised. Thick materials often mean handling heavy equipment and sharp tools, so using protective gear such as gloves and ensuring a well-lit work environment can prevent accidents. In conclusion, sewing thick materials demands a blend of the right equipment, precise techniques, and an understanding of the material's properties. An informed approach not only helps in overcoming the challenges associated with sewing these robust fabrics but also guarantees that the finished product is of high quality and professional caliber. Whether you're creating a durable canvas bag or hemming a pair of jeans, the satisfaction of mastering such challenging materials is a reward in itself, reflected in the resilience and beauty of your handcrafted creations.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025