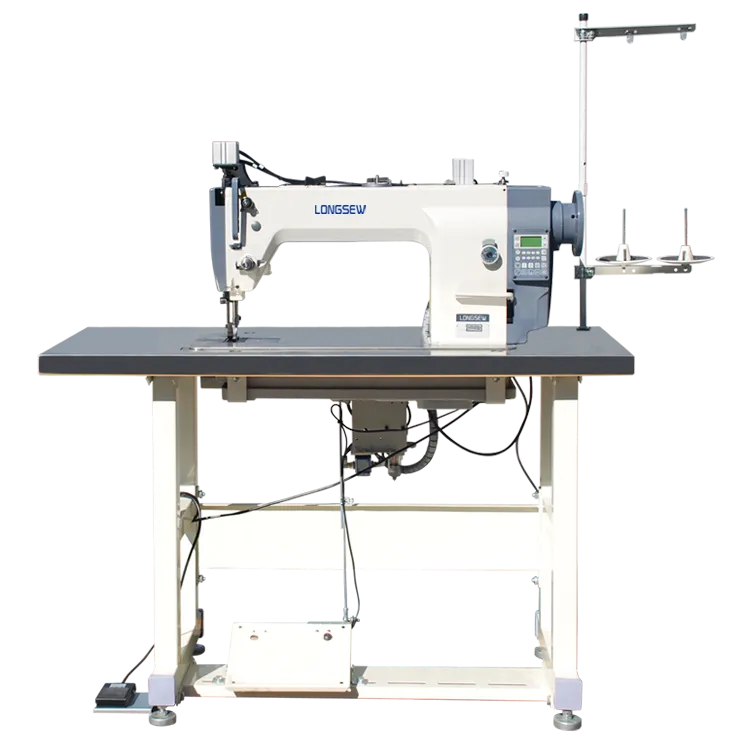

Innovative Seaming Machine Head for Enhanced Sewing Efficiency and Quality

Understanding Seaming Machine Heads Essential Components of Textile Manufacturing

In the ever-evolving world of textile manufacturing, the machinery used plays a pivotal role in the quality and efficiency of production processes. One key component that stands out is the seaming machine head. This specialized apparatus is integral to creating durable seams in various textiles, ensuring that the final products meet the highest standards of quality. In this article, we will delve into the various aspects of seaming machine heads, including their functions, types, and significance in the industry.

What is a Seaming Machine Head?

A seaming machine head is the primary working unit of a sewing machine, designed specifically for stitching two or more pieces of fabric together. These heads are equipped with various mechanisms, including needles, feed dogs, and thread tensioners, which work in unison to create reliable seams. The design and technology behind a seaming machine head can significantly influence the stitching speed, quality, and versatility of the sewing operation.

Types of Seaming Machine Heads

Seaming machine heads come in various types, each tailored to specific applications and fabric types

. These can be broadly categorized into the following1. Lockstitch Machine Heads These are the most common types used in sewing, creating a stitch by interlocking two threads. Lockstitch machines are ideal for lightweight to medium fabrics and are widely employed in garment manufacturing.

2. Overlock Machine Heads Overlock or serger machine heads trim the fabric edge while simultaneously sewing. They are particularly useful for knit fabrics and are widely used in knitwear production. Their ability to produce stretchable seams makes them indispensable for activewear and other elastic materials.

3. Coverstitch Machine Heads These machine heads are essential for hemming and finishing seams on knit fabrics. They create a durable, professional-looking finish, preventing fabric from unraveling while allowing for stretchability.

seaming machine head

4. Chainstitch Machine Heads Chainstitch heads create a series of interlocking loops, offering a unique stretchable seam. They are often used in producing heavy-duty items and decorative stitching due to their strong and flexible nature.

Importance of Seaming Machine Heads in Manufacturing

The significance of seaming machine heads in the textile manufacturing process cannot be overstated. Here are a few reasons why these components are crucial

1. Quality Assurance A well-functioning seaming machine head ensures that seams are tight and durable, reducing the likelihood of garment failure after production. This is particularly important in high-stress areas such as armholes, waistbands, and hems.

2. Increased Efficiency Modern seaming machine heads are engineered for speed and precision. By automating various functions and employing advanced technologies, manufacturers can significantly increase production rates while maintaining quality standards.

3. Versatility With a range of seaming machine heads available, manufacturers can cater to diverse product lines—from lightweight shirts to heavy-duty trousers. The ability to switch between different heads allows for flexibility in production, accommodating changing market demands.

4. Cost-Effectiveness Investing in high-quality seaming machine heads can lead to long-term cost savings. Quality seams reduce the need for rework and returns, enhancing profitability and customer satisfaction.

Conclusion

In summary, seaming machine heads are vital components within the textile manufacturing sector. Their design and functionality directly impact seam quality, production efficiency, and overall product durability. As fabric technology continues to evolve, so too will the innovation behind seaming machine heads, leading to even more sophisticated and efficient solutions for manufacturers. For anyone involved in textile production, understanding the intricate workings and benefits of seaming machine heads is essential to staying competitive in a fast-paced industry. Thus, investing in quality machinery is not just a necessity but a strategic move for long-term success in textile manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025