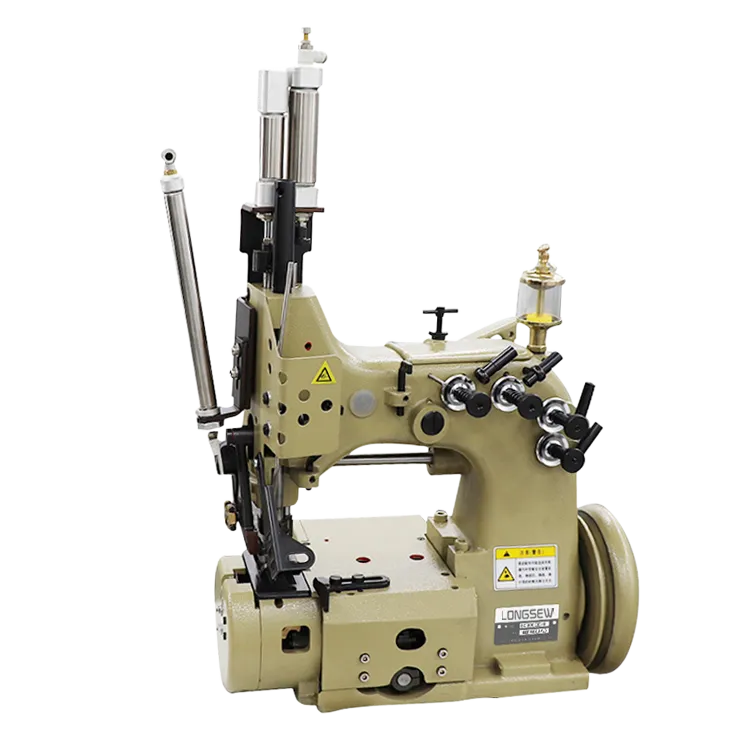

pp woven sack bag sewing machine

The Importance of PP Woven Sack Bag Sewing Machines in Packaging

In the ever-evolving world of manufacturing and packaging, the PP (polypropylene) woven sack bag has emerged as a popular choice for various industries, including agriculture, construction, and food packaging. The durability and versatility of these bags make them ideal for storing and transporting a wide range of products. However, the efficiency and quality of these sacks are greatly influenced by the sewing machines used in their production. PP woven sack bag sewing machines play a vital role in ensuring that these bags are strong, reliable, and capable of withstanding tough conditions.

Understanding PP Woven Sacks

PP woven sacks are made from woven polypropylene fibers. These bags are lightweight yet incredibly strong, making them suitable for carrying heavy loads. The woven structure provides excellent tear resistance, while the properties of polypropylene allow for moisture resistance and protection against environmental factors. As a result, they are widely used to package products like grains, fertilizers, chemicals, and various consumer goods.

The Role of Sewing Machines

The process of creating PP woven sacks involves weaving the polypropylene fibers into sheets, followed by cutting the sheets into the required sizes, and finally sewing them into bags. This is where PP woven sack bag sewing machines come into play. Equipped with advanced technology, these machines are designed to ensure precise and consistent stitching, which is crucial for maintaining the strength and integrity of the bags.

1. Efficiency One of the primary advantages of using specialized sewing machines for PP woven sacks is efficiency. These machines are capable of sewing multiple bags in a short amount of time, significantly reducing production time and increasing output. With features such as automatic feeding and cutting mechanisms, manufacturers can streamline their operations and focus on scaling their production.

2. Quality Control In an industry where the reliability of packaging can directly impact the overall quality of the product, consistency in stitching is paramount. PP woven sack bag sewing machines are designed to provide uniform stitches, ensuring that each bag produced meets the necessary quality standards. This reduces the likelihood of defects and enhances the overall durability of the sacks.

pp woven sack bag sewing machine

3. Versatility Another significant advantage of PP woven sack sewing machines is their versatility. These machines can be adjusted to accommodate different stitch types and bag sizes, making them suitable for a wide range of applications. Whether producing small bags for packaging seeds or larger ones for bulk commodities, manufacturers can rely on these machines to meet their specific requirements.

4. Cost-Effectiveness Investing in high-quality sewing machines can lead to long-term savings for manufacturers. By improving production efficiency and reducing waste, companies can lower their operational costs. Additionally, the durability of the bags created by these machines can lead to improved customer satisfaction and lower return rates, further enhancing profitability.

The Future of PP Woven Sack Production

As sustainability becomes an increasing concern in manufacturing, there is a growing demand for eco-friendly packaging solutions. The PP woven sack industry is evolving to meet these challenges through innovations in machine technology and materials. Manufacturers are looking to integrate more sustainable practices, such as using recycled polypropylene and developing biodegradable alternatives.

With the advancement of automation and smart technology, the future of PP woven sack bag sewing machines looks promising. Manufacturers can expect enhanced features that improve efficiency and reduce energy consumption while maintaining the quality of the output. Furthermore, the integration of Industry 4.0 principles can lead to smarter factories, capable of adaptive production based on real-time data.

Conclusion

The significance of PP woven sack bag sewing machines cannot be overstated in today's packaging industry. Their role in enhancing efficiency, quality control, versatility, and cost-effectiveness makes them essential for manufacturers aiming to meet the demands of modern markets. As the industry continues to embrace innovation and sustainability, these machines will undoubtedly evolve, playing a critical role in shaping the future of packaging solutions. Their impact extends beyond mere production; they contribute to the overall reliability and sustainability of the products we use daily.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025