PP Bag Closer Machine - High Efficiency and Reliability for Packaging Solutions

Innovations in PP Bag Closer Machines

In the world of packaging, efficiency and precision are paramount. This is particularly true for businesses dealing with polypropylene (PP) bags, which are widely used in agriculture, food, and industrial applications. The PP bag closer machine has emerged as a vital tool for manufacturers seeking to enhance their packaging processes.

A PP bag closer machine is designed specifically for sealing polypropylene bags, which are known for their durability, lightweight properties, and resistance to moisture. These machines ensure that bags are securely closed, preventing spillage during transport and storage. As businesses look for ways to improve productivity and reduce waste, investing in advanced PP bag closer machines has become increasingly important.

Innovations in PP Bag Closer Machines

One of the standout features of contemporary PP bag closer machines is their ability to customize sealing options. Businesses can choose from heat sealing, stitching, or ultrasonic sealing methods depending on their specific needs. Heat sealing, for instance, is particularly effective for creating a strong bond in materials like polypropylene, while stitching may be preferred for bags containing heavier materials. This versatility allows manufacturers to adapt to varying requirements effortlessly.

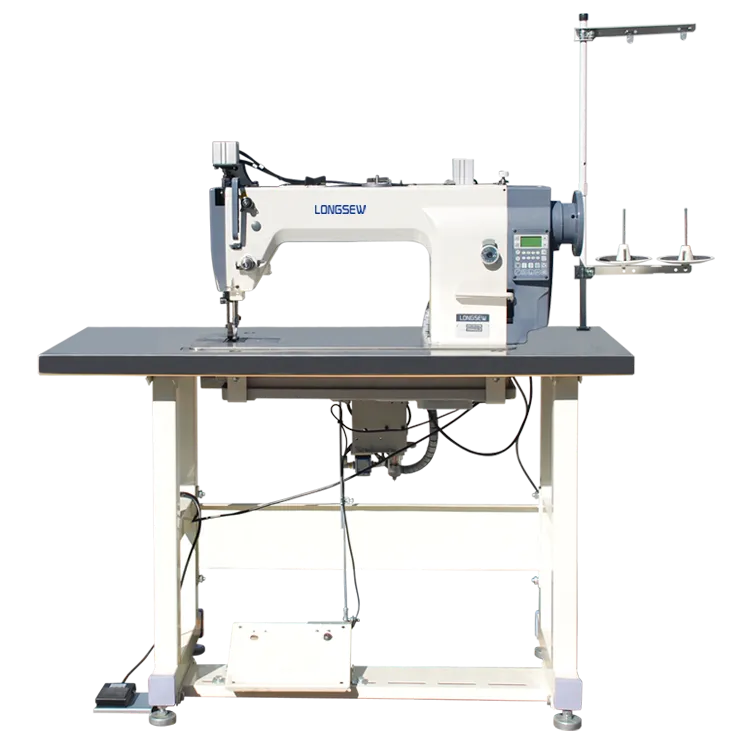

pp bag closer machine

Additionally, the user interface on modern machines has been significantly improved. Many PP bag closer machines now incorporate digital displays that provide real-time feedback on operating conditions, allowing operators to monitor the sealing process more effectively. Such advancements not only make the machines easier to operate but also enhance safety by providing crucial data at a glance.

Environmental considerations are also influencing the design of PP bag closer machines. As companies strive for sustainability, manufacturers are incorporating eco-friendly technologies that consume less energy and reduce waste. Some machines are designed to work with biodegradable materials, aligning with the growing demand for sustainable packaging solutions.

The global market for PP bag closer machines is expected to grow as more industries recognize the benefits of efficient bag sealing. With innovations continually emerging, businesses can look forward to even more advanced machines that further enhance their packaging operations.

In conclusion, the PP bag closer machine stands out as an essential component in the packaging industry. Its ability to improve efficiency, ensure product integrity, and adapt to diverse packing requirements positions it as a key investment for businesses aiming to thrive in a competitive marketplace. As technology advances, these machines will undoubtedly evolve, continuing to play a critical role in the future of packaging.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025