2月 . 13, 2025 09:45

Back to list

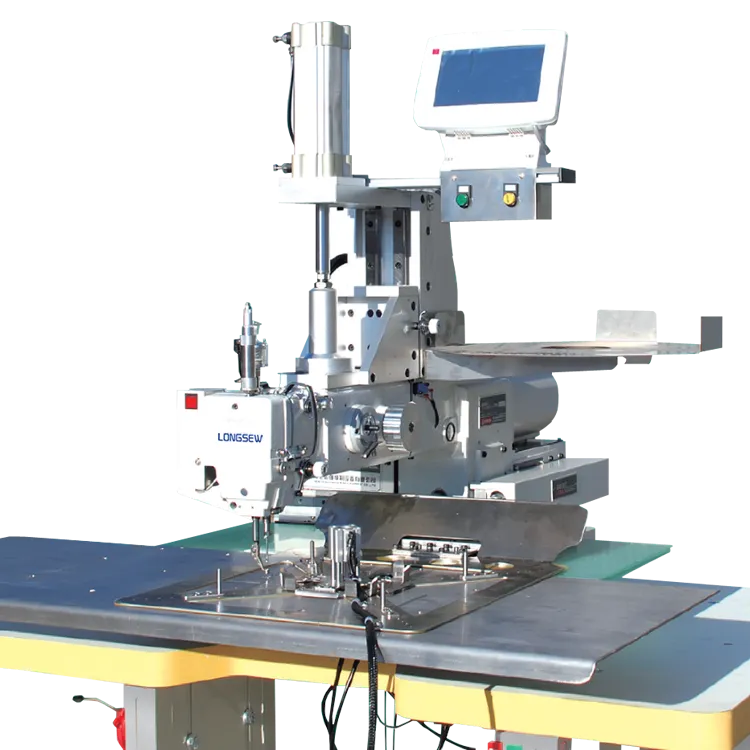

machine for sewing leather bags

Selecting a machine for sewing leather bags is a crucial decision for both budding and seasoned artisans. Leather, as a material, requires specialized equipment that can handle its thickness and resilience. Investing in the right sewing machine can enhance not only the quality of your creations but also your productivity and creativity.

Ease of maintenance is another consideration to make before purchase. Regular oiling and cleaning ensure that the machine runs smoothly without interruptions. Machines that provide easy access to crucial components simplify the maintenance process, reducing downtime and prolonging the lifespan of the equipment. Brands that offer excellent customer service and readily available replacement parts, such as Pfaff or Brother, also enhance the reliability and trust in your chosen equipment. Versatility in functionality is a desirable attribute of a leather sewing machine. Adjustable presser foot pressure, stitch length, and the ability to use various types of threads provide artisans with the flexibility to experiment with different designs and techniques. A machine that offers a walking foot feature is particularly valuable, as it helps in feeding the leather evenly through the machine, preventing any slippage or misalignment during sewing. Safety features should not be overlooked. Machines with automatic needle positioners and safety clutches protect both the user and the material from accidents and mishaps. The ability to halt machine operations instantly contributes to both safety and the ease of correcting errors when they occur. Lastly, the price is a practical consideration. Investing in a quality machine is a long-term commitment, and while cheaper options may seem appealing initially, they often lack the resilience and features necessary for proficient leather sewing. A mid-range or high-end machine might require a significant upfront investment, but the precision, efficiency, and durability they offer will provide significant returns in the quality of your leather bags and satisfaction in craftsmanship. Opting for the right sewing machine tailored to your needs and expertise level can significantly improve your leather bag production, ensuring each piece showcases exceptional craftsmanship and enduring quality. Research and trial should guide your choice, ensuring that the machine you select aligns with your creative aspirations and business goals.

Ease of maintenance is another consideration to make before purchase. Regular oiling and cleaning ensure that the machine runs smoothly without interruptions. Machines that provide easy access to crucial components simplify the maintenance process, reducing downtime and prolonging the lifespan of the equipment. Brands that offer excellent customer service and readily available replacement parts, such as Pfaff or Brother, also enhance the reliability and trust in your chosen equipment. Versatility in functionality is a desirable attribute of a leather sewing machine. Adjustable presser foot pressure, stitch length, and the ability to use various types of threads provide artisans with the flexibility to experiment with different designs and techniques. A machine that offers a walking foot feature is particularly valuable, as it helps in feeding the leather evenly through the machine, preventing any slippage or misalignment during sewing. Safety features should not be overlooked. Machines with automatic needle positioners and safety clutches protect both the user and the material from accidents and mishaps. The ability to halt machine operations instantly contributes to both safety and the ease of correcting errors when they occur. Lastly, the price is a practical consideration. Investing in a quality machine is a long-term commitment, and while cheaper options may seem appealing initially, they often lack the resilience and features necessary for proficient leather sewing. A mid-range or high-end machine might require a significant upfront investment, but the precision, efficiency, and durability they offer will provide significant returns in the quality of your leather bags and satisfaction in craftsmanship. Opting for the right sewing machine tailored to your needs and expertise level can significantly improve your leather bag production, ensuring each piece showcases exceptional craftsmanship and enduring quality. Research and trial should guide your choice, ensuring that the machine you select aligns with your creative aspirations and business goals.

Previous:

Latest news

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025