1月 . 23, 2025 01:29

Back to list

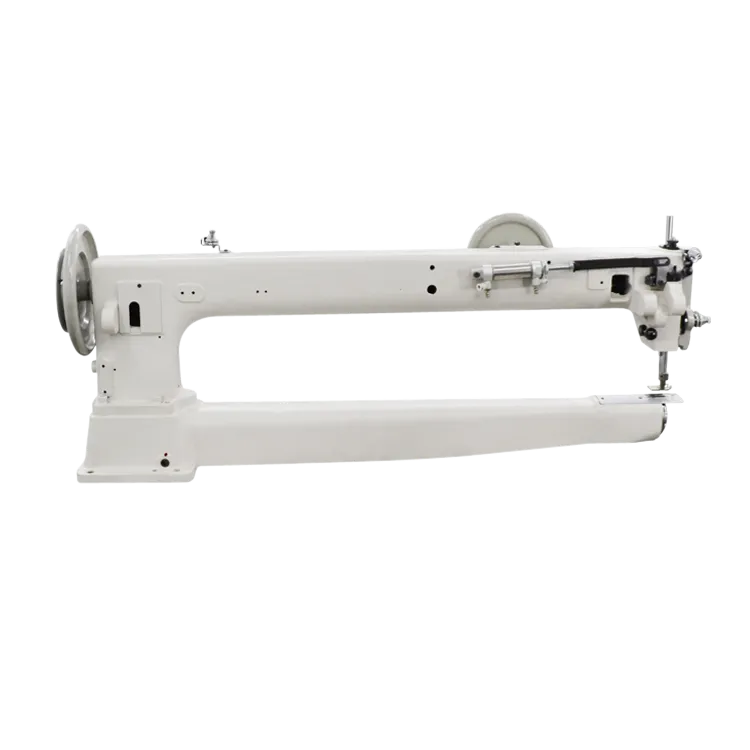

industrial chain stitch machine

When considering the intricacies of industrial chain stitch machines, one can't stress enough their indispensable role in the textile and apparel industries. These machines stand as the backbone of high-efficiency production lines and contribute significantly to the quality and durability of sewn products. Drawing on years of experience in textile manufacturing, this exploration delves into the nuances of these robust machines and provides a detailed understanding that will assist both seasoned professionals and newcomers in making informed decisions.

Trust in chain stitch machines also extends into the safety arena. Modern machines come equipped with features designed to minimize injury risks and enhance user-friendly operations. Safety mechanisms, such as needle guards and automatic thread cutters, have transformed the operational landscape, allowing even less experienced operators to work effectively with lower associated risks. This built-in safety aligns well with international standards and showcases the machine’s reliability. Furthermore, the technological advancements in recent years have seen the integration of digital interfaces and programmable features in many industrial chain stitch machines. These innovations provide an unprecedented level of control and precision, allowing for intricate pattern designs and complex stitching sequences. This digital leap forward not only improves productivity but also enhances the machine's adaptability to new trends and materials in the textile industry. For businesses prioritizing sustainability, many modern chain stitch machines offer eco-friendly options, such as energy-efficient motors and systems designed to minimize material waste. These features align well with the rising demand for sustainable production practices and demonstrate the machine’s evolving role in not just productivity but also environmental responsibility. The insight provided here paints a comprehensive picture of industrial chain stitch machines as an irreplaceable asset in the textile industry. Their proven efficiency, durability, and adaptability make them a central component of any large-scale garment production process. For industry professionals seeking to optimize their operations, understanding the technical specifications, capabilities, and maintenance practices of these machines is paramount. With the right combination of expertise and experience, businesses can leverage the power of chain stitch machines to achieve both high performance and superior product quality, all while navigating the constantly changing textiles landscape with authority and trustworthiness.

Trust in chain stitch machines also extends into the safety arena. Modern machines come equipped with features designed to minimize injury risks and enhance user-friendly operations. Safety mechanisms, such as needle guards and automatic thread cutters, have transformed the operational landscape, allowing even less experienced operators to work effectively with lower associated risks. This built-in safety aligns well with international standards and showcases the machine’s reliability. Furthermore, the technological advancements in recent years have seen the integration of digital interfaces and programmable features in many industrial chain stitch machines. These innovations provide an unprecedented level of control and precision, allowing for intricate pattern designs and complex stitching sequences. This digital leap forward not only improves productivity but also enhances the machine's adaptability to new trends and materials in the textile industry. For businesses prioritizing sustainability, many modern chain stitch machines offer eco-friendly options, such as energy-efficient motors and systems designed to minimize material waste. These features align well with the rising demand for sustainable production practices and demonstrate the machine’s evolving role in not just productivity but also environmental responsibility. The insight provided here paints a comprehensive picture of industrial chain stitch machines as an irreplaceable asset in the textile industry. Their proven efficiency, durability, and adaptability make them a central component of any large-scale garment production process. For industry professionals seeking to optimize their operations, understanding the technical specifications, capabilities, and maintenance practices of these machines is paramount. With the right combination of expertise and experience, businesses can leverage the power of chain stitch machines to achieve both high performance and superior product quality, all while navigating the constantly changing textiles landscape with authority and trustworthiness.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025