Affordable Pricing Options for Industrial Bag Sewing Machines

The Price of Industrial Bag Sewing Machines Factors and Considerations

In today's fast-paced manufacturing environment, industrial bag sewing machines play a crucial role in the production of various types of bags, including those used for packaging, storage, and retail purposes. The price of these specialized machines can vary significantly, influenced by several key factors. In this article, we will explore the aspects that determine the cost of industrial bag sewing machines, helping businesses make informed purchasing decisions.

Understanding Industrial Bag Sewing Machines

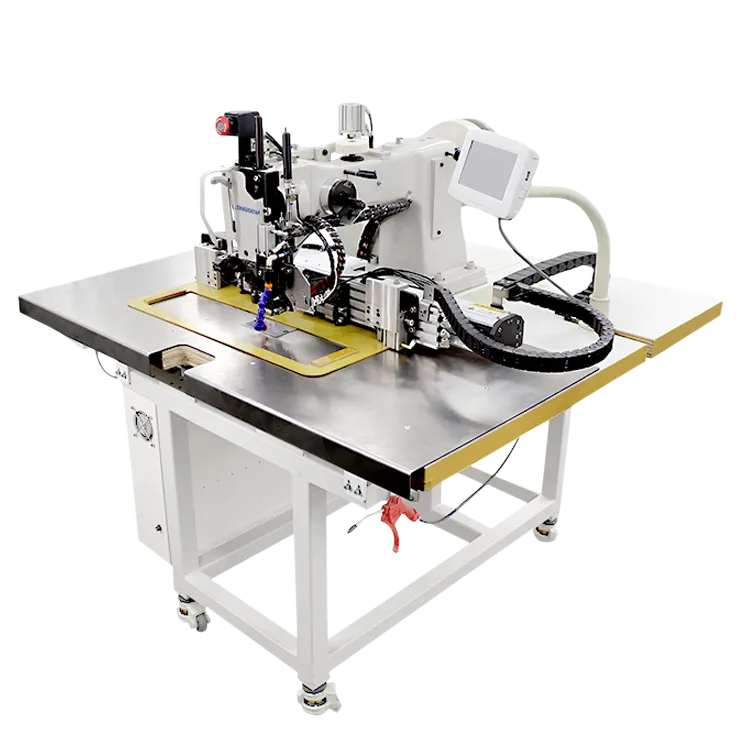

Industrial bag sewing machines are designed for high-performance sewing tasks, offering durability and efficiency compared to domestic sewing machines. They are commonly used to create bags from materials such as woven polypropylene, cotton, and other synthetic fabrics. Given the demand for bags in various industries, including agriculture, construction, and retail, the right sewing machine can enhance productivity and reduce labor costs.

Key Factors Influencing Prices

1. Type and Specifications The type of industrial bag sewing machine significantly impacts its price. There are various models tailored for specific needs—some for simple straight stitching, while others offer complicated stitching options, such as overlock or embroidery features. Machines equipped with advanced technology, such as programmable features and automation capabilities, generally come at a higher price point.

2. Brand Reputation Established brands with a history of reliability and innovation often charge premium prices for their machines. Buyers may be willing to invest more in reputable brands because these machines typically come with better warranties, customer support, and durability. Lesser-known brands may offer more budget-friendly options but could lack the same level of service and reliability.

3. Materials and Build Quality The materials used in the construction of the sewing machine will also influence the price. Machines constructed from high-quality, durable components are designed to withstand the rigors of continuous use in an industrial setting. While these machines may have a higher initial cost, they can result in lower long-term maintenance and replacement costs.

industrial bag sewing machine price

4. Technological Features As technology continues to evolve, many industrial bag sewing machines are now equipped with cutting-edge features such as automatic thread trimming, digital controls, and enhanced safety mechanisms. These advancements can increase the price, but they also improve efficiency and reduce the risk of operator error, making them a worthwhile investment for many businesses.

5. Market Demand and Economic Factors The prices of industrial sewing machines can also fluctuate based on market demand and broader economic conditions. High demand for certain types of bags, influenced by seasonal trends or economic growth in specific sectors, can lead to increased prices. Additionally, global supply chain issues can affect machine availability and cost.

Making an Informed Purchase

When considering the purchase of an industrial bag sewing machine, it’s essential for businesses to conduct thorough research. Comparing different models, understanding their features, and assessing their long-term value versus initial investment will help businesses choose the right machine for their needs. Establishing a budget that considers not just the purchase price but also maintenance, operation costs, and potential downtime is critical.

Furthermore, considering future production needs and scalability is important. A machine that is moderately priced but can be upgraded or adapted for different applications in the future might be a smarter choice than a cheaper, less versatile option.

Conclusion

The price of industrial bag sewing machines reflects a range of factors including type, brand, build quality, technology, and market dynamics. By carefully evaluating these elements, businesses can make informed decisions that balance cost with long-term productivity and reliability. Investing in the right machine can significantly enhance operational efficiency and contribute to overall business success in the competitive world of industrial manufacturing.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025