Industrial Bag Sewing Machine Price - Affordable Rates for Quality Machines

The Cost of Industrial Bag Sewing Machines A Comprehensive Overview

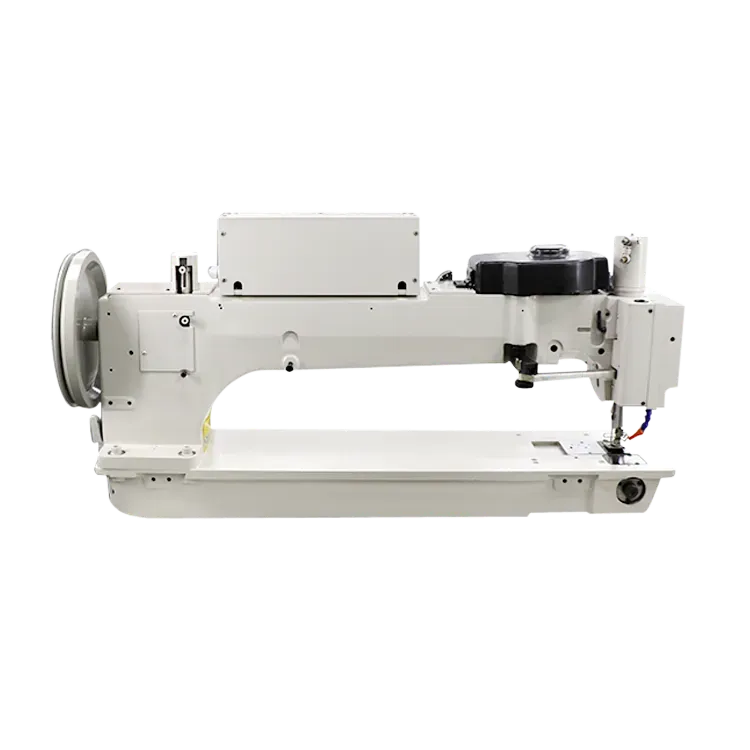

In the textile and manufacturing industries, industrial bag sewing machines play a crucial role in the production of various types of bags, including tote bags, shopping bags, and packaging bags. As businesses seek to optimize their production processes, the choice of machinery becomes increasingly important. One key factor that often comes to the forefront is the price of industrial bag sewing machines. This article explores the pricing landscape, influencing factors, and the potential return on investment associated with these essential machines.

Understanding the Price Range

The price of industrial bag sewing machines can vary greatly based on several parameters. Typically, you might find prices ranging from a few hundred to several thousand dollars. Entry-level machines suitable for small-scale operations may start at around $500, while advanced models equipped with automation features and higher production capacities can exceed $10,000.

Factors Influencing Price

Several factors contribute to the price differences in industrial bag sewing machines

1. Brand Renowned brands often command higher prices due to their reputation for durability and reliability. Purchasing a machine from a well-established manufacturer can be a wise investment, as these machines are generally designed for heavy use.

2. Machine Type Different types of sewing machines serve various purposes. For instance, a simple sewing machine may be less expensive compared to a multi-functional machine that can perform sewing, cutting, and sealing operations—all vital for bag production.

industrial bag sewing machine price

3. Features and Specifications Machines equipped with advanced features such as automatic thread trimming, programmable stitch patterns, and higher stitch speeds tend to be more expensive. Businesses must evaluate the features they truly need to avoid overspending.

4. Material Compatibility The ability of a sewing machine to handle different materials, such as thick canvas or synthetic fabrics, can also affect pricing. Machines that can operate effectively on a wider variety of materials usually cost more.

5. Production Capacity High-capacity machines that can produce large volumes of bags quickly are generally more expensive. Companies focusing on mass production might find that investing in these machines pays off in terms of efficiency and productivity.

Evaluating the Return on Investment

When considering the purchase of an industrial bag sewing machine, it is crucial to evaluate the potential return on investment (ROI). While it may be tempting to choose a lower-priced machine, this decision could have long-term implications on productivity and quality. On the other hand, investing in a high-quality machine may lead to less downtime, improved output rates, and better overall product quality.

Moreover, businesses should factor in maintenance and operational costs, as these can significantly influence the total expenditure over the lifespan of the machine. A more expensive machine may require fewer repairs and less frequent replacements, enhancing overall cost efficiency.

Conclusion

In summary, the price of industrial bag sewing machines varies and is influenced by a multitude of factors including brand, type, features, material compatibility, and production capacity. While making a purchase decision, businesses should carefully weigh these factors against their operational needs and budget. Ultimately, investing in the right machine can enhance productivity, efficiency, and product quality, leading to a substantial return on investment in the competitive landscape of the textile and packaging industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025