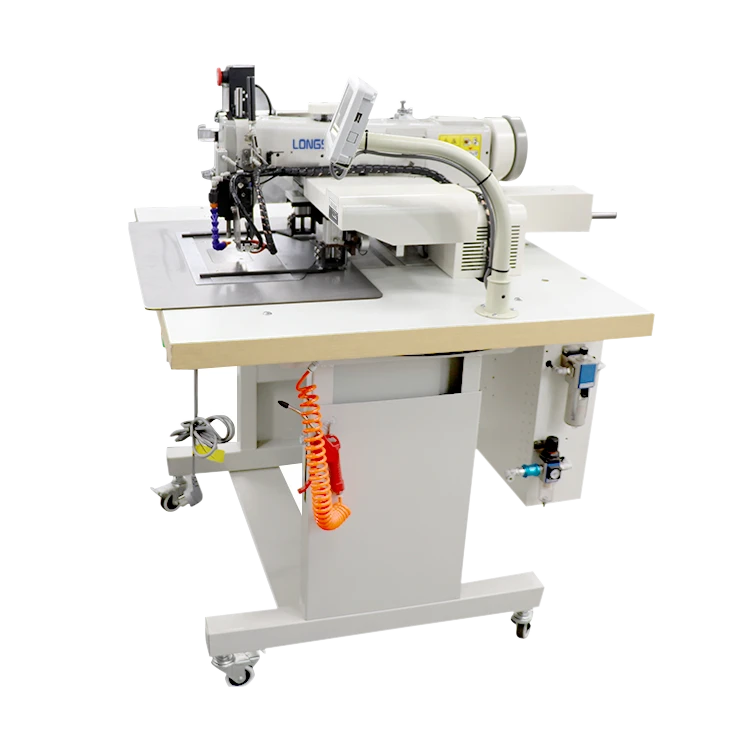

High-Performance Industrial Overlock Machines for Professional Sewing and Tailoring Needs

Understanding Industrial Serger Machines A Key Tool in Modern Textile Production

Industrial serger machines, also known as overlock machines, play a crucial role in the textile industry by providing efficient and high-quality stitching solutions. These machines are essential for both large-scale manufacturing and small-scale operations, offering versatility and precision that are unmatched by traditional sewing methods. This article will explore the mechanics, benefits, and applications of industrial serger machines, shedding light on why they are indispensable in modern textile production.

Mechanics of Industrial Serger Machines

At the core of an industrial serger machine is its unique stitching mechanism. Unlike standard sewing machines that typically use one needle and two threads, sergers incorporate multiple threads (often four or more) and multiple needles to create a robust seam. This multi-thread system allows for a variety of stitches, including overlock, rolled hems, and cover stitches.

One of the standout features of sergers is their ability to trim the fabric edges while sewing. The machine’s built-in blade cuts the fabric as it feeds through, which helps prevent fraying and creates a professional finish. This feature not only speeds up the production process but also ensures that the final product is neat and durable. With adjustable settings for stitch length, width, and tension, operators can customize the machine for different fabric types and project requirements.

Benefits of Using Industrial Serger Machines

The primary advantage of industrial serger machines is their efficiency. In a fast-paced industry where time is money, the ability to sew and finish edges simultaneously can significantly reduce production times. Sergers are designed for heavy-duty use and can handle a wide range of fabric types, from lightweight cotton to heavier denim and knit materials, making them extremely versatile.

industrial serger machines

Furthermore, sergers produce seams that are not only aesthetically pleasing but also structurally sound. The multi-threaded stitch allows for stretch, which is particularly beneficial for garments that require flexibility, such as activewear and swimwear. This characteristic minimizes the risk of seams ripping, thus enhancing the longevity of the finished products.

Additionally, sergers come equipped with various features that enhance usability. Some models offer automatic tension adjustment, differential feed for handling stretchy or delicate fabrics, and built-in stitch options, allowing users to experiment and achieve the desired finish without additional equipment.

Applications in the Textile Industry

Industrial serger machines find applications across a broad spectrum of textile and garment manufacturing sectors. They are widely used in the production of ready-to-wear clothing, lingerie, and sports apparel. The functionality of these machines extends beyond garment creation; they are also employed in the production of home textiles, upholstery, and even industrial fabrics.

Moreover, sergers are invaluable in alterations and repairs. Their ability to provide a clean finish helps tailor items to fit perfectly, giving customers a polished look even when adjustments are made.

Conclusion

In conclusion, industrial serger machines are vital tools in the textile industry, enhancing production efficiency and product quality. Their ability to combine cutting, sewing, and finishing in one operation makes them indispensable for manufacturers. As the demand for quality textiles continues to rise, investing in high-performance sergers will remain a critical element for businesses aiming to stay competitive in this dynamic sector. With technology continuously evolving, the future of industrial serger machines promises even greater innovations, ensuring they remain at the forefront of textile production for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025