1月 . 26, 2025 02:52

Back to list

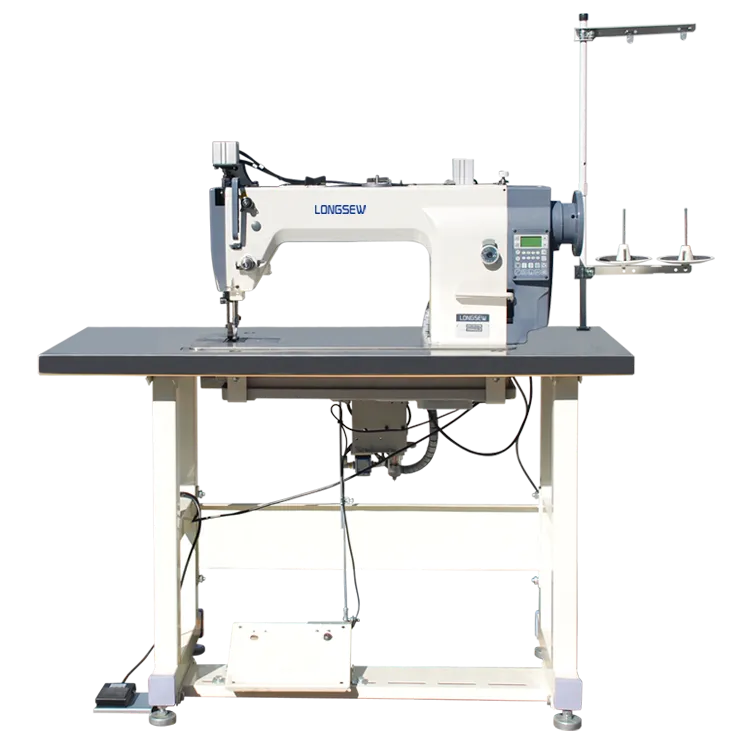

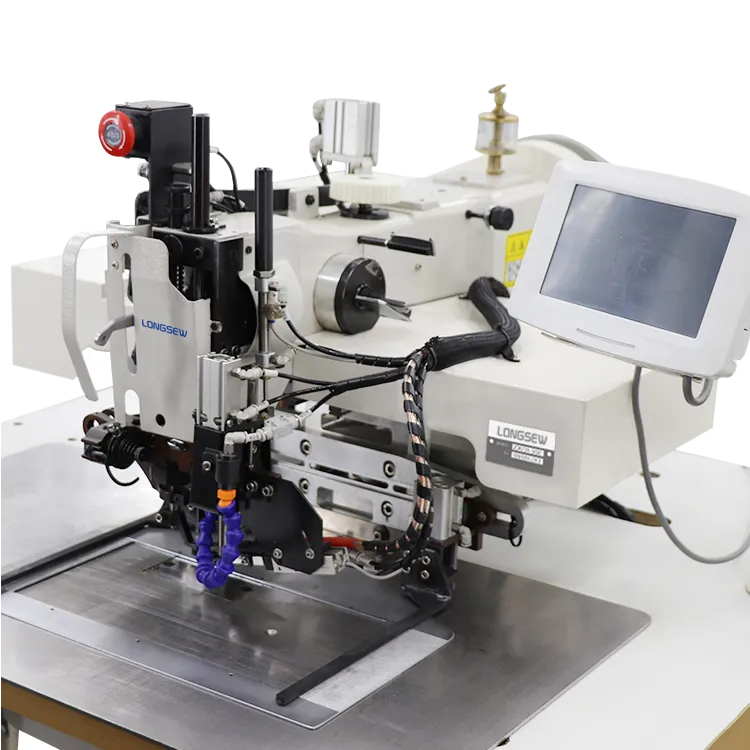

Fishing Net Hauling Rope Single Needle 3 Threads Overedging Sewing Machine 81500CZ

Exploring the heavy duty bag closer sewing machine, you're venturing into a realm of exceptional utility in industrial sewing. This machine is not just another piece of equipment; it is the lifeline of effective packaging operations across various industries, from agriculture to manufacturing. With decades of developments refined for precision and durability, these machines are indispensable for businesses aiming for efficiency and reliability in sealing bulk bags.

Trustworthiness is a crucial factor when selecting a heavy duty bag closer. Leading brands in the market incorporate state-of-the-art technologies that increase machine reliability. They offer superior customer support and stringent quality assurance processes, which include rigorous pre-shipment inspections and component testing analyses. This attention to detail builds confidence in their machines, ensuring that clientele can trust the machines to meet high operational standards. The environmental impact of using a heavy duty bag closer sewing machine is an often overlooked benefit. By securely sealing bags, these machines reduce material waste spillage, and product loss during transportation and storage, leading to more sustainable practices. Furthermore, advancements in machine efficiency also mean that less energy is required to achieve high-speed operation, reducing their overall carbon footprint. For businesses considering purchasing a heavy duty bag closer, it is crucial to identify the correct model that meets specific operational needs. Consulting with industry specialists can guide this decision, leveraging their experience to recommend features such as adjustable sewing head heights and programmable panel interfaces. These consultations ensure that each machine is tailored for optimal performance within its intended environment. In conclusion, a heavy duty bag closer sewing machine is far more than a simple sewing tool; it is a foundational piece of the industrial packaging process. Its combination of durability, precision, and efficiency makes it a valuable asset to any business involved in large-scale bagging operations. Trust remains at the core of its successful implementation—from the reliability of the machine itself to the expertise needed to operate and maintain it. Whether you're ensuring a batch of grains reaches its destination intact or packaging industrial parts, these machines safeguard the integrity of each product they enwrap. Invest in quality, operate with professionalism, and harness the true potential of this remarkable industrial tool.

Trustworthiness is a crucial factor when selecting a heavy duty bag closer. Leading brands in the market incorporate state-of-the-art technologies that increase machine reliability. They offer superior customer support and stringent quality assurance processes, which include rigorous pre-shipment inspections and component testing analyses. This attention to detail builds confidence in their machines, ensuring that clientele can trust the machines to meet high operational standards. The environmental impact of using a heavy duty bag closer sewing machine is an often overlooked benefit. By securely sealing bags, these machines reduce material waste spillage, and product loss during transportation and storage, leading to more sustainable practices. Furthermore, advancements in machine efficiency also mean that less energy is required to achieve high-speed operation, reducing their overall carbon footprint. For businesses considering purchasing a heavy duty bag closer, it is crucial to identify the correct model that meets specific operational needs. Consulting with industry specialists can guide this decision, leveraging their experience to recommend features such as adjustable sewing head heights and programmable panel interfaces. These consultations ensure that each machine is tailored for optimal performance within its intended environment. In conclusion, a heavy duty bag closer sewing machine is far more than a simple sewing tool; it is a foundational piece of the industrial packaging process. Its combination of durability, precision, and efficiency makes it a valuable asset to any business involved in large-scale bagging operations. Trust remains at the core of its successful implementation—from the reliability of the machine itself to the expertise needed to operate and maintain it. Whether you're ensuring a batch of grains reaches its destination intact or packaging industrial parts, these machines safeguard the integrity of each product they enwrap. Invest in quality, operate with professionalism, and harness the true potential of this remarkable industrial tool.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025