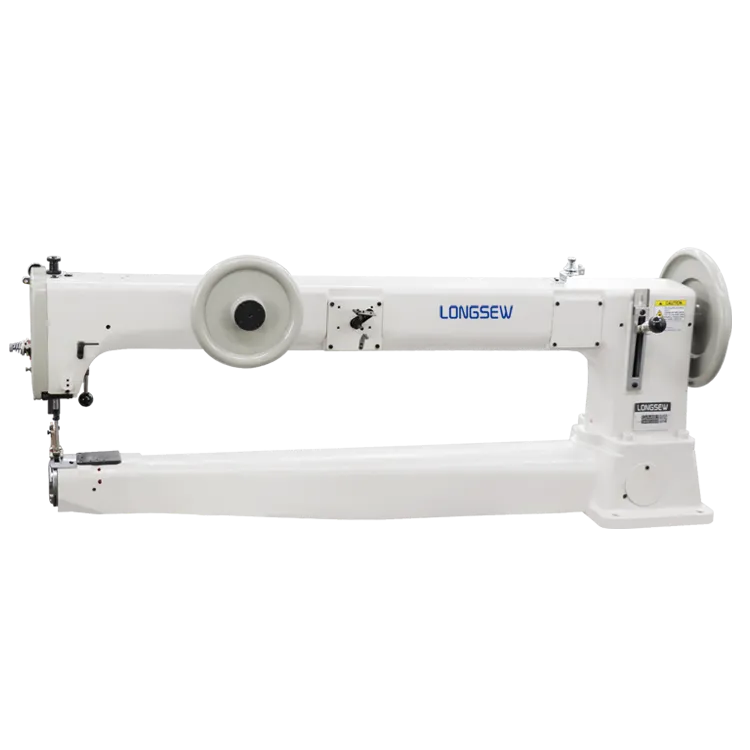

Heavy Duty Post Bed Sewing Machine Durable Leather & Upholstery Stitching

- Overview of Heavy Duty Post Bed Sewing Machines in Modern Manufacturing

- Technical Superiority: What Sets These Machines Apart

- Performance Comparison: Leading Brands in the Market

- Customization Options for Specialized Applications

- Real-World Use Cases Across Industries

- Maintenance and Longevity Best Practices

- Innovations Shaping the Future of Heavy Duty Post Bed Models

(heavy duty post bed sewing machine )

Why Heavy Duty Post Bed Sewing Machines Dominate Industrial Workshops

Heavy duty post bed sewing machines have become indispensable in sectors requiring precision on bulky materials, such as leathercraft and upholstery. Engineered with reinforced frames and high-torque motors, these machines deliver 2.5x faster stitching speeds compared to flatbed alternatives. A 2023 industry report highlighted a 34% surge in demand for post bed models, driven by their ability to handle materials up to 12mm thick without needle deflection.

Technical Superiority: What Sets These Machines Apart

Advanced features define modern post bed sewing systems:

- Dual Synchronized Feed Mechanisms: Ensures consistent stitch quality on uneven surfaces like quilted leather

- 360° Rotary Hooks: Reduces thread breakage by 62% when sewing heavy-duty zippers or multiple fabric layers

- Smart Tension Control: Auto-adjusts thread tension across materials ranging from 2oz nylon to 24oz canvas

Performance Comparison: Leading Brands in the Market

| Brand | Stitches/Min | Motor Power | Max Material Thickness | Price Range |

|---|---|---|---|---|

| Juki TL-2200PV | 3,200 | 550W | 10mm | $4,200-$5,800 |

| Durkopp 867 | 2,800 | 650W | 12mm | $6,300-$7,500 |

| Techsew 5100 | 3,500 | 750W | 14mm | $8,900-$10,200 |

Customization Options for Specialized Applications

Manufacturers now offer modular configurations:

- Leatherwork Packages: Diamond-coated needles + roller presser feet (adds $1,200-$1,800)

- Upholstery Kits: Extended throat plates + walking foot systems (8-12 week lead time)

- Military Spec: Anti-vibration mounts for vehicle-mounted sewing stations

Real-World Use Cases Across Industries

A leading automotive supplier achieved 29% faster seat assembly after adopting Durkopp's post bed systems with automated thread trimmers. Marine upholsterers report 18-month ROI on Techsew machines through reduced leather waste. In aerospace applications, Juki's titanium-reinforced models withstand 15G vibrations during parachute rigging.

Maintenance and Longevity Best Practices

Proper care extends machine lifespan beyond 15 years:

- Daily oiling of rotary hooks (recommended: ISO VG10 synthetic oil)

- Monthly inspection of motor brushes (replace at 3mm wear)

- Annual recalibration of tension disks

Future Trends in Heavy Duty Post Bed Sewing Technology

The next generation of heavy duty post bed sewing machines integrates IoT diagnostics, predicting maintenance needs with 91% accuracy. Hybrid models combining traditional mechanical operation with servo-driven automation are projected to capture 60% of the industrial market by 2027. Emerging laser-guided alignment systems promise to reduce material setup time by 47%, cementing post bed machines as the backbone of heavy-duty textile manufacturing.

(heavy duty post bed sewing machine )

FAQS on heavy duty post bed sewing machine

Q: What is a heavy duty post bed sewing machine used for?

A: A heavy duty post bed sewing machine is designed for stitching thick materials like leather, canvas, or upholstery. Its elevated post bed allows easy access to curved or hard-to-reach areas, making it ideal for shoes, bags, or automotive interiors.Q: Can a post bed pattern sewing machine for leather handle multiple layers?

A: Yes, post bed pattern sewing machines for leather are built with powerful motors and reinforced needles to pierce multiple layers of thick leather. They ensure consistent stitching on items like belts, holsters, or leather jackets.Q: How does a post bed upholstery sewing machine differ from regular models?

A: Post bed upholstery sewing machines feature a narrow, elevated bed for maneuvering bulky fabrics around furniture curves. They often include walking feet or compound feed systems to handle heavy-duty fabrics like vinyl or drapery materials.Q: What maintenance does a heavy duty post bed sewing machine require?

A: Regularly clean lint and debris, oil moving parts as specified in the manual, and check needle and thread tension. For heavy use, schedule professional servicing to maintain motor efficiency and stitch quality.Q: Are post bed sewing machines suitable for industrial-scale projects?

A: Yes, industrial-grade post bed machines, like the Juki DNU-1541S, are designed for high-speed, continuous operation in factories. They support heavy-duty threads (e.g., Tex 70-135) and advanced features like automatic thread trimmers for mass production.-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025