Good Heavy Duty Leather Sewing Machine Best for Leather & Upholstery

- Understanding Leather Sewing Machine Fundamentals

- Technical Specifications Breakdown

- Top Manufacturer Comparison Analysis

- Custom Solutions for Specialized Applications

- Upholstery Projects: Real-World Application

- Maintenance Strategies for Longevity

- Investment Considerations for Professionals

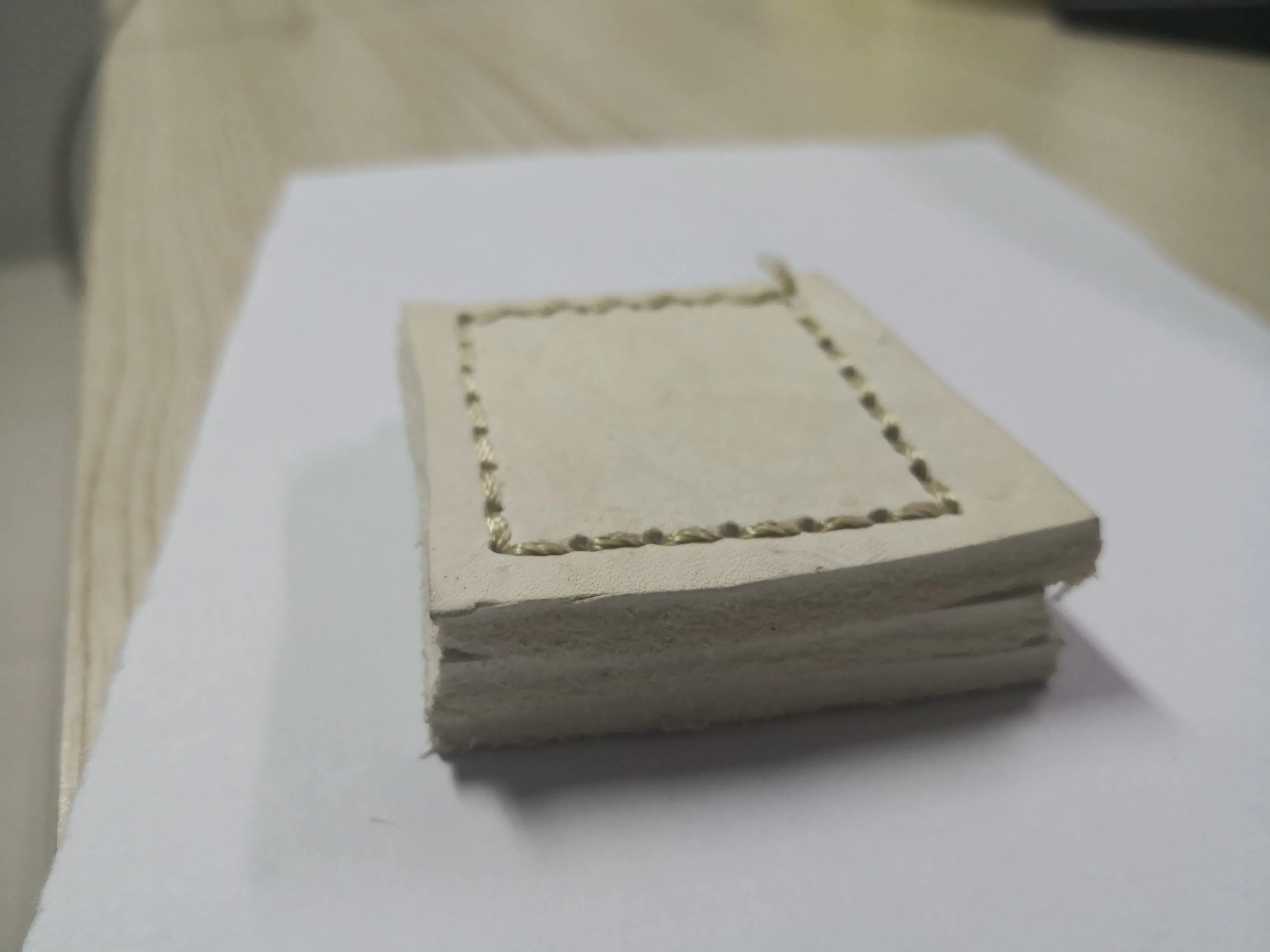

(good leather sewing machine)

Finding the Right Good Leather Sewing Machine for Your Workshop

Selecting the proper equipment for leatherwork demands understanding mechanical fundamentals. Industrial-grade motors distinguish professional equipment from domestic units, with brushless DC motors providing consistent torque without overheating during prolonged stitching. Machines handling full-grain leather require at least 0.4 horsepower - equivalent to 300W power output - to penetrate multiple material layers without thread breakage or skipped stitches. The feed mechanism proves equally critical: compound feed systems with seven-point feed dogs maintain precise material control, preventing the layer shifting that ruins precision projects.

Technical Specifications That Matter

Several specifications determine operational capacity. Needle penetration force between 30-45 Newtons handles thick upholstery vinyls and bridle leather without deflection. Consider machines offering adjustable presser foot pressure between 600-800 grams for material-sensitive applications. The differential feed ratio deserves particular attention for upholstery work; models with 2:1 ratios prevent puckering when joining vinyl to foam backing. Additional features include:

- Extended throat space (8-14 inches) enabling circular stitching on bags

- Automatic thread trimmers saving 7-9 seconds per seam

- Programmable stitch patterns for decorative edge treatments

Industrial Machine Comparison Analysis

| Model | Motor Power | Max Speed (SPM) | Stitch Length (mm) | Throat Space | Materials Capacity |

|---|---|---|---|---|---|

| Juki 1541S | 0.5 HP | 2,500 | 3.5-7.5 | 9" | 10oz leather + webbing |

| Sailrite Fabricator | 0.67 HP | 1,600 | 2.0-6.0 | 7.5" | 1/4" vinyl stack |

| Techsew 510 Pro | 0.7 HP | 3,500 | 4.0-8.0 | 12" | 12oz saddle leather |

| Consew 206RB | 0.8 HP | 3,200 | 3.0-7.0 | 10.5" | Automotive interiors |

Custom Solutions for Specialized Needs

Specialized operations require tailored configurations. Shoemaking operations implement cylinder-bed modifications for circular stitching operations, with narrow-bed attachments reducing material handling time by 40% compared to flatbed conversions. Aircraft interior specialists install dual-needle setups for parallel topstitching at 8 SPI (stitches per inch) precision. Aftermarket modifications include:

- Walking foot attachments for laminated materials ($180-$320)

- Servo-motor retrofits reducing power consumption by 65%

- Reverse stitch regulators preventing leather deformation

Upholstery Application Case Studies

Furniture workshops report significant efficiency gains when implementing proper machinery. Maritime upholsterers processing marine vinyl utilize machines with integrated fabric tensioners, preventing material stretch during curved seam construction. Production data from Smith & Sons Upholstery demonstrates:

- Production increase from 15 to 28 automotive seats per 8-hour shift

- Thread consumption reduction of 23% after implementing automatic tension control

- Rejected pieces decreasing from 12% to 3% after adopting triple-feed systems

Maintenance Protocols for Maximum Durability

Protecting equipment investment requires disciplined upkeep. Daily maintenance includes brush-clearing feed dogs and lubricating hook assemblies with ISO VG10 synthetic oil. Monthly protocols encompass:

- Belt tension verification (deflection ≤ 1/2 inch at 4lbs pressure)

- Needle bar alignment checks using laser calibration tools

- Electronic tension meter validation (±0.05N variance tolerance)

Annual overhaul procedures involve replacing timing belts every 3,500 operational hours and rewiring motors every five years - critical for preventing workshop electrical fires.

Why Investing in a Good Sewing Machine for Upholstery Delivers Returns

Professional-grade equipment proves cost-effective long-term. Compared to domestic machines requiring $380 annual maintenance, industrial units average $150 upkeep costs despite heavier workloads. Operations processing 800+ linear yards monthly achieve 18-month ROI through increased throughput and reduced material waste. Critical calculations include:

- $25/hour labor savings from automated features

- 50% reduction in leather scrap from precise stitching control

- Extended service intervals reducing technician fees by 40%

The right machine configuration transforms challenging projects into profitable endeavors while preserving material integrity throughout thousands of stitching cycles.

(good leather sewing machine)

FAQS on good leather sewing machine

Q: What makes a sewing machine good for leather work?

A: Good leather sewing machines feature powerful motors to penetrate thick hides, heavy-duty metal frames for stability, and specialized needles/feed systems. They must handle multiple layers without skipping stitches while providing consistent tension control.

Q: How do I identify a truly heavy-duty sewing machine?

A: Look for industrial-grade motors (≥1 amp), full metal internal gears/components, and high presser foot lift (≥12mm). Genuine heavy-duty machines include reinforced hooks, extra-large sewing beds, and can continuously sew through denim, canvas, or vinyl without strain.

Q: What features matter most in upholstery sewing machines?

A: Key features include extended table space for large projects, walking foot or compound feed systems to grip thick fabrics evenly, and powerful piercing capability. Machines should offer adjustable presser foot pressure and handle heavyweight threads like Tex 70.

Q: Can a heavy-duty machine sew both leather and upholstery?

A: Yes, quality heavy-duty machines typically handle both if they have interchangeable presser feet and adjustable settings. Models with servo motors provide optimal control for varying material thicknesses, transitioning smoothly from leather bags to furniture fabrics.

Q: Why choose a dedicated leather machine over regular heavy-duty models?

A: Dedicated leather machines offer specialized features like synchronized needle feed, powerful piercing technology, and presser feet designed for sticky materials. These provide superior stitch accuracy on leather compared to standard heavy-duty machines.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025