fibc sealing sewing machine

The Importance of FIBC Sealing Sewing Machines in Modern Manufacturing

In today's fast-paced industrial landscape, the demand for efficient and reliable packaging solutions has never been higher. One of the standout innovations in the field of bulk packaging is the Flexible Intermediate Bulk Container (FIBC), commonly known as bulk bags. These bags are essential for storing and transporting bulk materials, ranging from agricultural products to chemicals. However, to ensure the integrity and effectiveness of FIBCs, the sealing and sewing processes employed in their production are crucial. This is where FIBC sealing sewing machines come into play.

Understanding FIBC

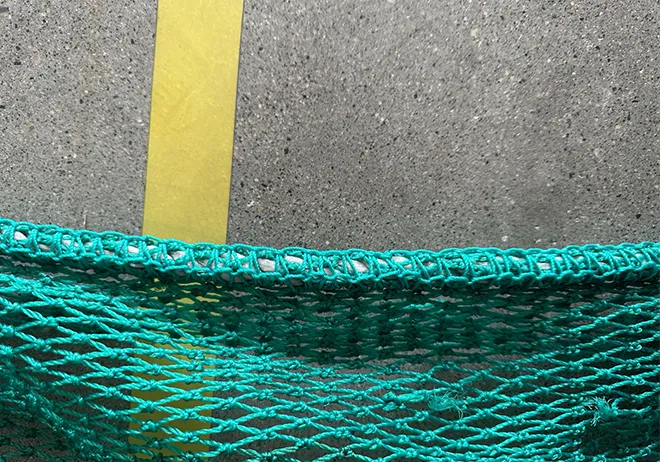

FIBCs are designed to hold large quantities of materials, with capacities typically ranging from 500 kg to 2000 kg and beyond. Made from woven polypropylene fabric, they offer strength, flexibility, and lightweight properties, making them ideal for transportation and storage. Given their large sizes and the nature of the materials they carry, it is vital that FIBCs are constructed with robust sealing mechanisms. This is where the quality of the sewing and sealing processes directly impacts the performance and durability of the bags.

The Role of FIBC Sealing Sewing Machines

FIBC sealing sewing machines are specialized equipment designed to meet the unique requirements of sewing and sealing these large bulk bags efficiently. These machines are engineered to handle thick woven materials that standard sewing machines may struggle with. Here are some key aspects of these machines that enhance their effectiveness

1. Durability and Strength FIBC sewing machines utilize heavy-duty components to withstand the rigors of sewing thick polypropylene fabric. The needles are designed to penetrate multiple layers of material, ensuring strong seams that can withstand significant stress and weight.

2. Precision The sealing process must be precise to prevent leaks and ensure the contents remain secure during transport. Advanced technology in FIBC sewing machines allows for accurate stitching and even tension throughout the seam. This precision is particularly important for bags used to transport fine powders or sensitive materials.

fibc sealing sewing machine

3. Speed and Efficiency In a manufacturing environment, time is of the essence. FIBC sealing sewing machines are designed for rapid production without compromising quality. High-speed operation capabilities allow manufacturers to produce bulk bags efficiently, meeting demand without delays.

4. Automated Features Modern FIBC sewing machines often come equipped with automated features such as automatic thread trimming, stitch regulation, and programmable sewing patterns. These features reduce labor costs and increase production efficiency while maintaining high-quality standards.

5. Versatility While designed primarily for FIBCs, many sealing sewing machines offer versatility to accommodate other types of bags and materials. This adaptability makes them a valuable investment for manufacturers who require the flexibility to shift production lines as market demands change.

Conclusion

The importance of FIBC sealing sewing machines cannot be overstated in the context of modern manufacturing and logistics. As industries continue to grow and evolve, the need for reliable bulk packaging solutions will only increase. By ensuring that FIBCs are sewn and sealed to the highest standards, manufacturers can guarantee product integrity, reduce waste, and improve overall efficiency in their operations.

Moreover, with an increasing emphasis on sustainability, the production of environmentally friendly packaging solutions can benefit from the use of advanced FIBC sealing sewing machines. These machines not only support the production of reusable and recyclable bulk bags but also foster a more sustainable approach to packaging and transporting goods.

In summary, investing in FIBC sealing sewing machines is not just about meeting immediate production needs; it is a step towards long-term reliability, efficiency, and sustainability in an ever-competitive market. As the demand for bulk bags continues to rise, manufacturers who prioritize quality sealing and sewing processes will find themselves ahead in the game, ready to tackle the challenges of future packaging needs.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025