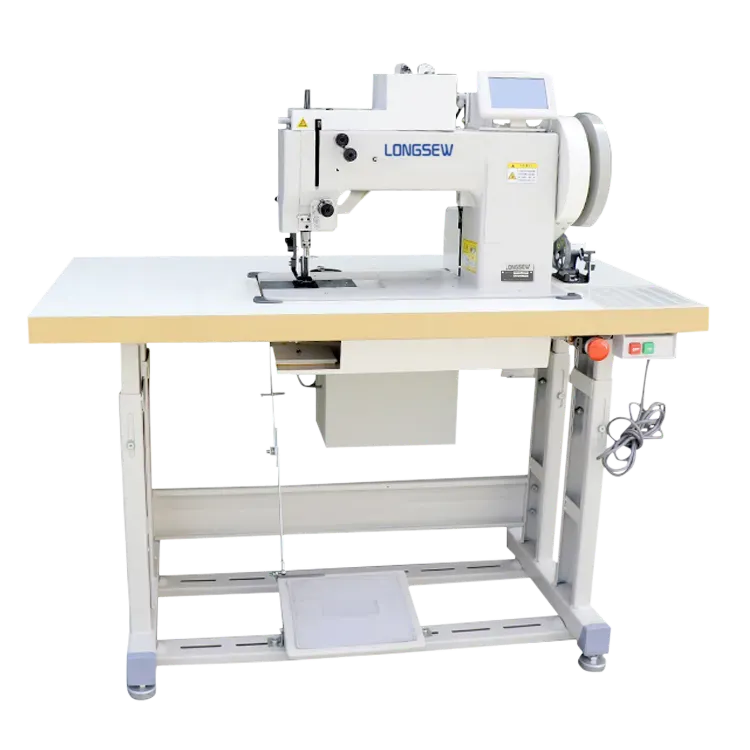

fibc bag lockstitch sewing machine

The Importance of FIBC Bag Lockstitch Sewing Machines in Industrial Applications

In the realm of industrial packaging, Flexible Intermediate Bulk Containers (FIBCs), commonly referred to as bulk bags, are indispensable. These versatile bags are designed to transport and store bulk materials, making them vital in industries ranging from agriculture to chemicals. A crucial aspect of ensuring the integrity and functionality of FIBC bags is the sewing process, which is typically accomplished with specialized sewing machines. Among these, the lockstitch sewing machine stands out as a vital tool for manufacturers.

What is an FIBC Bag Lockstitch Sewing Machine?

A lockstitch sewing machine is a type of sewing machine that uses two threads - a needle thread and a bobbin thread - to create a locked stitch. This method is particularly beneficial for creating strong and durable seams that are essential for the heavy-duty nature of FIBC bags. The construction of these bags requires robust seams that can withstand the rigors of handling, transportation, and storage of bulk materials. Without the strength provided by lockstitch seams, bags may fail, leading to material loss and potential safety hazards.

Advantages of Lockstitch in FIBC Bag Manufacturing

1. Strength and Durability Lockstitch seams are renowned for their strength. The intertwined threads create a sturdy seam that can handle the immense weight of bulk materials without tearing. This durability is crucial when transporting granular substances like sand, grains, or powders, where the bags may face abrasive conditions.

2. Versatility Lockstitch sewing machines can accommodate various thread types and thicknesses, making them suitable for different FIBC bag materials, including polypropylene (PP) and polyethylene (PE). This versatility ensures that manufacturers can produce bags tailored for specific applications and customer needs.

fibc bag lockstitch sewing machine

3. Speed and Efficiency Modern lockstitch sewing machines are designed for high-speed operation. This efficiency is vital in a production environment where timely delivery is key. Faster sewing processes help manufacturers meet demand without compromising quality.

4. Automatic Features Many of today’s lockstitch machines come equipped with automatic features that enhance productivity, such as automatic thread cutting, sewing speed control, and programmable patterns. These features minimize downtime and increase overall output, which is essential for keeping pace with the growing demand for FIBC bags in various industries.

Maintenance and Care

To ensure optimal performance, regular maintenance of lockstitch sewing machines is critical. Routine check-ups should include cleaning, lubrication, and timely replacement of worn parts. Proper maintenance extends the life of the machines and ensures consistent seam quality, which is paramount for the reputation of manufacturers in the FIBC market.

Conclusion

FIBC bag lockstitch sewing machines play a pivotal role in the manufacturing process of bulk bags, contributing significantly to the strength, durability, and efficiency of the final product. As industries increasingly rely on FIBCs for transporting materials, the demand for reliable sewing technology will continue to grow. Manufacturers must invest in advanced lockstitch sewing machines to meet this demand and ensure their products can withstand the challenges of the supply chain.

In summary, the lockstitch sewing machine is not just a tool; it is a cornerstone of the FIBC manufacturing process, ensuring that the bags produced are not only functional but also capable of delivering performance and reliability in the field.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025