Understanding the Functionality of a Double Needle Chain Stitch Sewing Machine

The Double Needle Chain Stitch Machine An Essential Tool in Modern Textile Manufacturing

In the ever-evolving world of textile manufacturing, efficiency and precision are paramount. Among the myriad of machinery available, the double needle chain stitch machine stands out as a crucial innovation. This machine has gained popularity in various sectors, including garment production, upholstery, and industrial applications, due to its versatility and the unique stitch it creates.

Understanding Double Needle Chain Stitch Technology

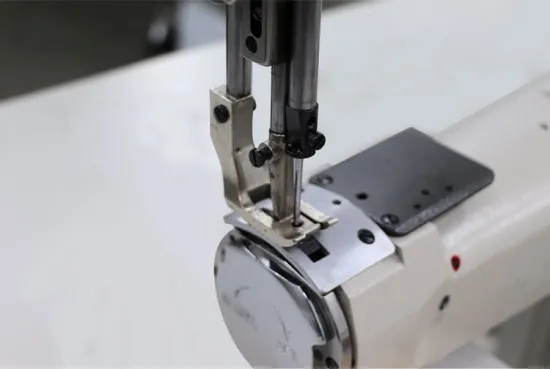

The double needle chain stitch machine utilizes two needles to create two parallel rows of stitches, which are connected by a chain of interlooped threads. This design allows for a robust seam, making it particularly useful for stretch fabrics and heavy materials. The chain stitch is characterized by its elasticity and durability, which not only enhances the aesthetics of the finished product but also contributes to its longevity.

The machine operates using a set of advanced mechanisms that ensure precision. The dual needles can be adjusted for different spacing, permitting a range of stitch widths to accommodate various fabric types and designs. Additionally, the machine typically features adjustable tension controls, which enable operators to fine-tune thread tension based on the specific requirements of their projects.

Advantages of Using a Double Needle Chain Stitch Machine

1. Enhanced Durability The chain stitch produced by this machine is known for its strength. The interlocking nature of the stitches means that the seams are less likely to unravel, making it ideal for items that undergo frequent stress, such as activewear and work uniforms.

2. Greater Elasticity The elasticity of the double needle chain stitch is particularly beneficial for sewing stretch fabrics. This feature ensures that the seams can accommodate movement without breaking, providing comfort to the wearer and extending the life of the garment.

double needle chain stitch machine

3. Versatility in Applications From casual wear to high-end fashion, the double needle chain stitch machine can be employed across various applications. It is commonly used for topstitching, hems, and decorative stitching, allowing manufacturers to create intricate designs while maintaining functionality.

4. Increased Production Speed The efficiency of the double needle chain stitch machine allows for faster production times compared to conventional single-needle machines. This boost in productivity is crucial in meeting market demands and keeping up with fast fashion trends.

5. Reduced Fabric Damage Traditional sewing methods often risk damaging delicate fabrics. The precise stitching of the double needle chain stitch minimizes this threat, ensuring that the fabric's integrity is preserved throughout the sewing process.

Challenges and Considerations

While the double needle chain stitch machine offers numerous benefits, it is not without challenges. It requires skilled operators who understand how to adjust the settings based on fabric type and desired stitch. Improper use can lead to issues such as skipped stitches or fabric puckering. Additionally, maintenance is essential to keep the machine in optimal working condition, as wear and tear can affect stitching quality over time.

Conclusion

In conclusion, the double needle chain stitch machine is a vital asset in modern textile manufacturing. Its ability to produce durable, elastic seams and accommodate various fabric types makes it an indispensable tool for garment producers and industrial manufacturers alike. As the demand for high-quality, efficient production continues to rise, the importance of such specialized machinery will only grow, underpinning the success of the textile industry in the years to come. With the right skills and maintenance, the double needle chain stitch machine will certainly remain a cornerstone of innovation in sewing technology.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025