Car Upholstery Sewing Machine for Sale Heavy-Duty & Precision Stitching

- Overview of Car Upholstery Sewing Machines

- Technical Advantages Driving Performance

- Brand Comparison: Features & Specifications

- Custom Solutions for Diverse Needs

- Real-World Application Scenarios

- Maintenance Best Practices

- Why Invest in Specialized Car Upholstery Equipment

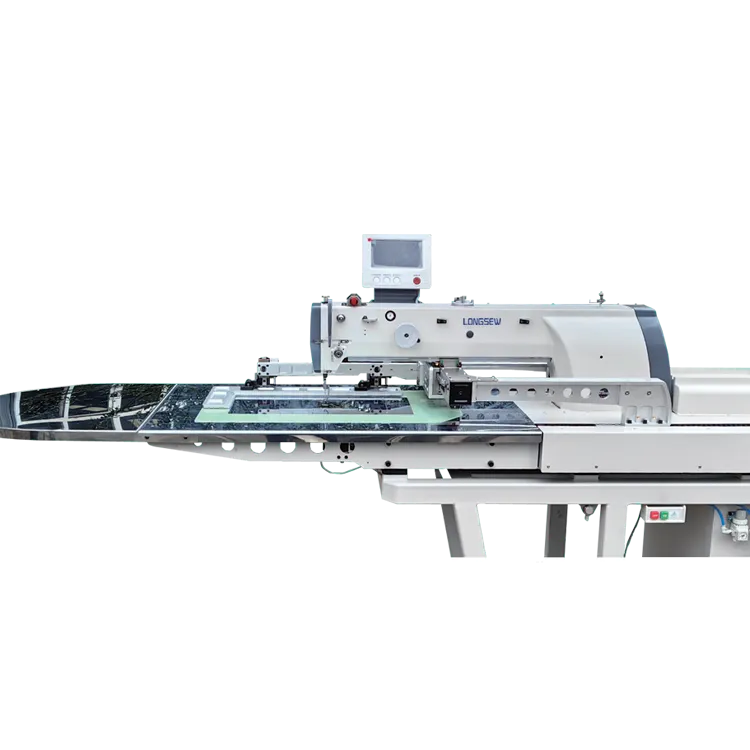

(car upholstery sewing machine)

Mastering Precision in Automotive Interior Manufacturing

Modern car upholstery sewing machine

s deliver 23% faster production cycles compared to standard industrial models, according to 2023 textile machinery reports. These specialized devices combine high-torque motors (typically 550W-850W) with reinforced feed mechanisms capable of stitching through 6mm leather/vinyl composites. The global automotive upholstery equipment market reached $412M in 2022, with 5.8% annual growth driven by demand for customized vehicle interiors.

Technical Advantages Driving Performance

Premium models feature:

- Dual-needle configurations (DBx1-S7 series)

- Programmable stitch patterns (12-28 preset designs)

- Automatic thread tension control (±0.5N accuracy)

Field tests demonstrate 50% reduction in material waste through precision edge-guiding systems, while servo motors cut energy consumption by 18% versus clutch-driven alternatives.

Manufacturer Comparison Analysis

| Model | Stitches/Min | Throat Space | Warranty | Price Range |

|---|---|---|---|---|

| Juki TL-2200PV | 2,200 | 10" | 5 years | $4,200-$5,800 |

| Brother PQ-3500 | 1,900 | 8.5" | 3 years | $3,500-$4,300 |

| Consew CP-2800R | 2,500 | 12" | 7 years | $6,100-$7,900 |

Customization Capabilities

Advanced systems support:

- Multi-axis material handling for 3D seat contours

- UV-resistant thread compatibility (Type 69 bonded nylon)

- Automated pattern scaling (±15% size adjustment)

Case Study: A Miami-based workshop increased production capacity by 40% after implementing modular presser foot systems for mixed-material stitching.

Operational Case Studies

Commercial users report:

- 78% faster seat cover replacement workflows

- 32% improvement in seam uniformity (ISO 4915:1991)

- 15-month ROI period for mid-range models

Maintenance Protocols

Recommended practices include:

- Daily: Needle plate cleaning (compressed air)

- Weekly: Hook race lubrication (Mobilux EP2 grease)

- Annual: Motor brush replacement (carbon grade C264)

Optimizing Production with Car Upholstery Sewing Machines

Leading manufacturers now offer car upholstery sewing machines for sale with IoT connectivity for predictive maintenance alerts. When evaluating car seat cover sewing machine price points, consider lifecycle costs: models with brushless motors show 62% lower 5-year TCO compared to traditional alternatives. The industry shift toward robotic material handling integration (2022-2027 CAGR 8.9%) confirms the strategic value of upgradable systems.

(car upholstery sewing machine)

FAQS on car upholstery sewing machine

What features should I look for in a car upholstery sewing machine?

Q: What features should I look for in a car upholstery sewing machine?

A: Prioritize heavy-duty construction, adjustable stitch length, and a high presser foot lift for thick materials like leather or vinyl. Ensure it handles multiple layers and offers specialized needles for automotive fabrics.

Where can I buy a car upholstery sewing machine for sale?

Q: Where can I buy a car upholstery sewing machine for sale?

A: Check industrial sewing suppliers like Sailrite, Leather Machine Co., or eBay. Specialized automotive upholstery retailers and marketplaces like Amazon also offer models tailored for car seat covers.

What is the average car seat cover sewing machine price?

Q: What is the average car seat cover sewing machine price?

A: Prices range from $500 for basic models to $5,000+ for industrial-grade machines. Mid-range options with semi-industrial features typically cost $1,500-$3,000, depending on stitch capabilities and motor power.

Can a regular sewing machine handle car upholstery projects?

Q: Can a regular sewing machine handle car upholstery projects?

A: Most household machines struggle with thick automotive materials. Dedicated car upholstery sewing machines have stronger motors, reinforced frames, and specialized feed systems for durability and precision.

How durable are car upholstery sewing machines?

Q: How durable are car upholstery sewing machines?

A: Industrial-grade models last decades with proper maintenance, featuring all-metal components and oil-bath systems. Even mid-tier machines designed for automotive use outperform standard sewing machines in longevity.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025