Efficient Solutions for Bag Sealing Equipment and Technology

The Evolution and Importance of Bag Sealing Machines

In the world of packaging, efficiency and reliability are paramount. One of the most critical components of the packaging process is sealing. Bag sealing machines play an essential role in ensuring that products are securely packaged, preventing contamination and prolonging shelf life. This article delves into the evolution, types, advantages, and future of bag sealing machines.

Historical Background

The concept of sealing bags can be traced back to ancient times, when artisans would stitch or tie bags shut to protect their contents. However, with the advent of the industrial revolution in the 18th and 19th centuries, new sealing methods began to emerge. As manufacturing processes evolved, so did the technology behind bag sealing. The invention of heat sealing in the mid-20th century marked a significant milestone, as it allowed for quicker and more effective sealing than traditional methods.

Types of Bag Sealing Machines

Today, bag sealing machines come in various types, each designed to meet specific packaging needs.

1. Heat Sealers These machines use heat to melt the edge of the bag, forming a secure seal. They are widely used in industries such as food and pharmaceuticals, where maintaining sterility and freshness is crucial. Heat sealers can be further categorized into impulse sealers, which heat only at the moment of sealing, and continuous sealers, which operate in a continuous flow.

2. Vacuum Sealers By removing air from the bag before sealing, vacuum sealers provide an extra layer of protection against spoilage. They are commonly used for packaging perishable goods, helping to extend shelf life considerably.

3. Automatic Bagging Machines These machines integrate sealing with automated bagging processes, enhancing productivity. They are often used in large-scale manufacturing environments, where speed and efficiency outweigh manual operations.

4. Band Sealers Featuring a conveyor belt, band sealers allow bags to move through the sealing mechanism, ideal for high-volume production. These machines are versatile and can handle various bag materials and sizes.

5. Mini Sealers Designed for small businesses or home use, mini sealers are compact and easy to operate. They are perfect for sealing small amounts of products or leftovers, providing convenience without sacrificing quality.

Advantages of Bag Sealing Machines

The use of bag sealing machines comes with numerous advantages.

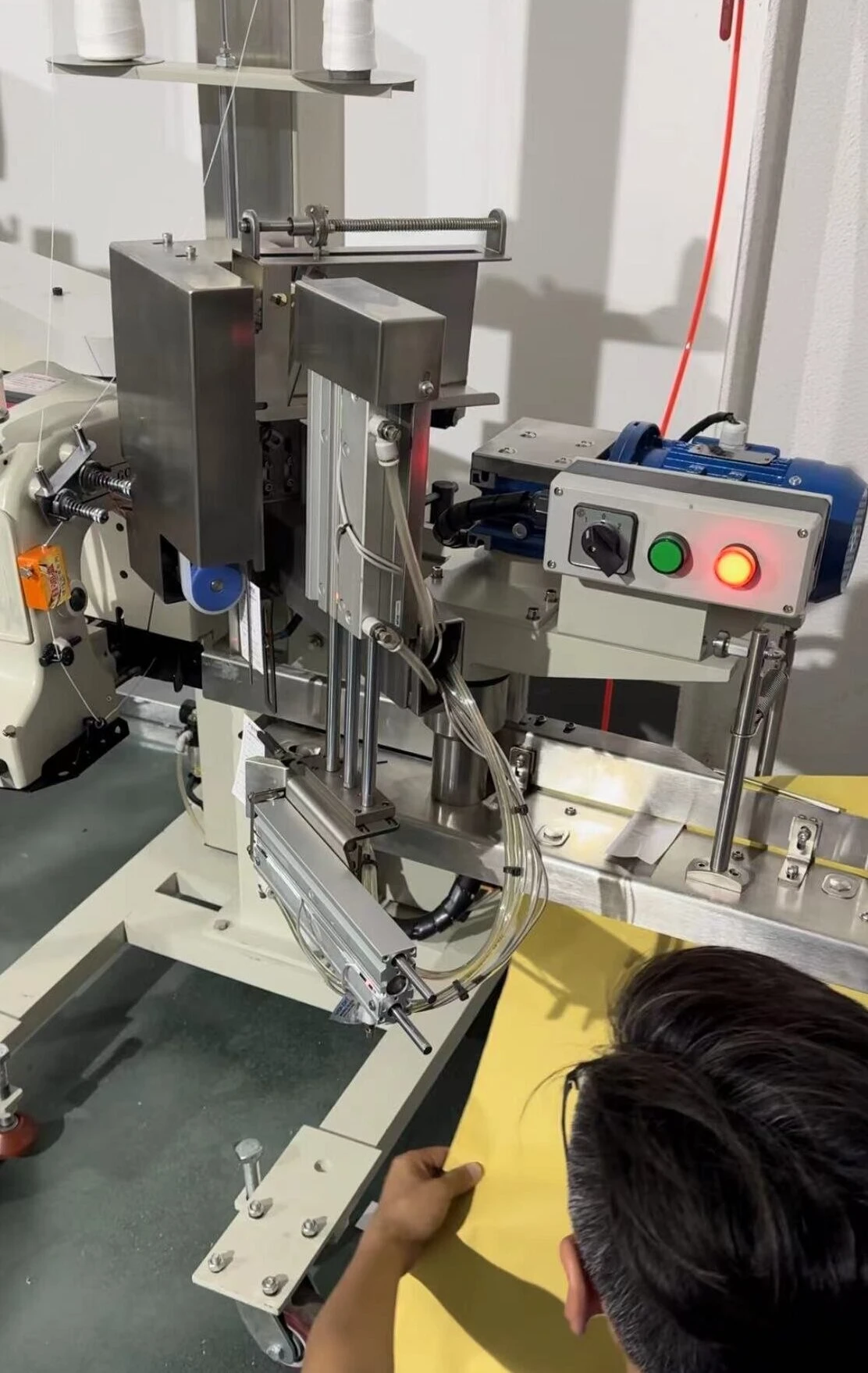

bag sealing machine

- Enhanced Product Freshness Sealing bags effectively eliminates air exposure, significantly extending the life of food products and other perishables

.- Cost Efficiency Automation and improved sealing technology reduce labor costs and minimize material waste due to damaged packages or spoiled products.

- Consistency Machines provide uniform seals, ensuring that every bag is sealed to the same standard, essential for brands focusing on quality control.

- Safety and Hygiene By packaging products securely, bag sealing machines help maintain hygiene standards, reducing the risk of contamination.

- Customization Many modern bag sealing machines offer customization options to accommodate different bag sizes and materials, making them adaptable to various industries.

Future Trends in Bag Sealing Technology

As consumer demands evolve, so too does the technology behind bag sealing machines. Innovations in the industry include

- Sustainability With an increasing focus on environmental sustainability, manufacturers are developing eco-friendly sealing options. This includes using biodegradable materials and minimizing plastic usage in packaging.

- Smart Technology The integration of IoT (Internet of Things) capabilities allows for monitoring and controlling sealing processes remotely. This can enhance efficiency, reduce downtime, and provide valuable data to improve operations.

- Increased Automation As industries strive for higher efficiency, more advanced automation technology will likely become commonplace in bag sealing machines, reducing the need for human intervention and increasing output.

- Advanced Materials Research into new bag materials that are easier to seal or provide better protection will influence the design and functionality of sealing machines.

Conclusion

Bag sealing machines are an indispensable part of the packaging landscape, offering solutions that enhance productivity, ensure product longevity, and maintain hygiene. As technology continues to advance and consumer needs evolve, bag sealing machines will adapt, incorporating new features and capabilities that drive the industry forward. Investing in the right sealing technology not only benefits businesses but also ensures that consumers receive high-quality products that meet their expectations. The future indeed looks bright for bag sealing machines, as they continue to play a critical role in packaging and supply chain management.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025