bag making machine

The Evolution and Importance of Bag Making Machines

In the modern world, where packaging plays a crucial role in commerce and retail, bag making machines have become indispensable in the manufacturing sector. These specialized machines are designed to produce a variety of bags efficiently, catering to different needs in industries ranging from retail to agriculture, and even pharmaceuticals.

Historical Perspective

The journey of bag making machines began with traditional manual methods. Before the advent of mechanization, bags were sewn or crafted by hand, using simple tools and manual labor. This process was labor-intensive and limited in scale, making it challenging to meet the growing demands of consumers. As businesses expanded, the need for faster and more efficient production methods became apparent. The introduction of bag making machines in the 20th century revolutionized the industry, allowing manufacturers to produce bags at an unprecedented pace and with greater consistency and quality.

Types of Bag Making Machines

Today, there are various types of bag making machines available, each designed to produce specific types of bags

. Some of the most common types include1. Plastic Bag Making Machines These machines are used to manufacture polyethylene bags for various applications, including shopping bags and trash bags. They operate using extrusion technology, where plastic resin is melted and formed into a continuous film, which is then cut and sealed to create bags.

2. Paper Bag Making Machines With a rising emphasis on sustainability, paper bags have gained popularity. These machines are designed to create eco-friendly paper bags suitable for retail and food service. They can produce different styles, including flat, square, and pinch-bottom bags.

3. Woven and Non-Woven Bag Making Machines These machines cater to the manufacture of reusable bags often used for shopping. Non-woven bag machines are particularly popular due to their eco-friendly properties and durability.

4. Pouch Making Machines Designed for the production of stand-up pouches, these machines are commonly used in the food industry and can accommodate various closures like zippers and spouts.

bag making machine

Features and Technologies

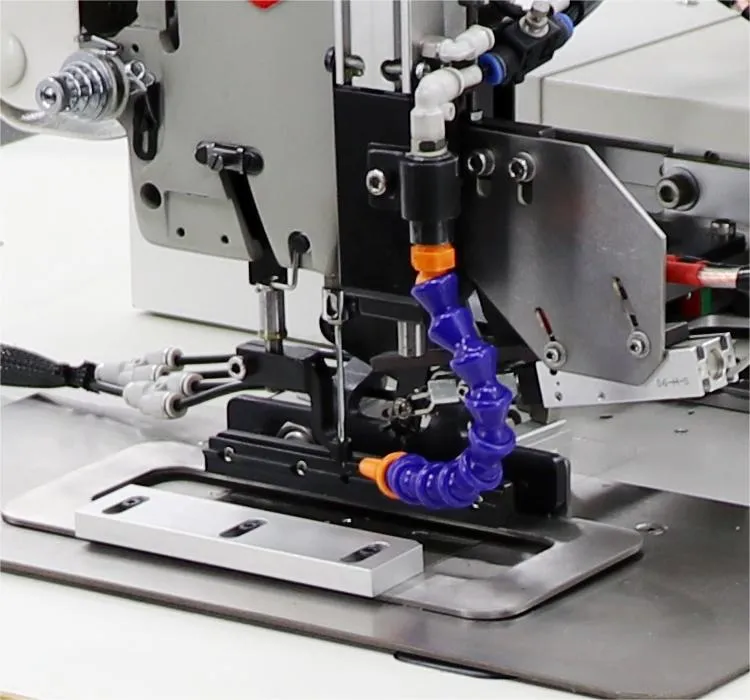

Modern bag making machines are equipped with advanced technologies that enhance efficiency and productivity. Features such as automatic film feeding, multi-functional cutting, and sealing mechanisms streamline the bag production process. Some machines come with computer controls that allow operators to program precise bag dimensions, ensuring minimal waste and optimal use of materials.

Additionally, innovations in machine design have led to faster production speeds, capable of producing thousands of bags per hour. Automation plays a significant role in these advancements, reducing the need for manual labor and minimizing human error, which contributes to higher quality outputs.

Environmental Considerations

As the global focus shifts towards sustainability, manufacturers of bag making machines are also adapting to the demand for eco-friendly alternatives. The rise of biodegradable and recyclable materials has influenced machine design and functionality. Many manufacturers now offer machines that can process recycled materials or produce bags that meet strict environmental regulations. This evolution is not only beneficial for the planet but also aligns with consumer preferences for sustainable products.

Economic Impact

Bag making machines significantly impact the economy by boosting production efficiency and enabling businesses to meet market demands swiftly. They allow companies to lower production costs, improve product quality, and increase profit margins. Furthermore, the growth of this industry has created numerous jobs, from manufacturing and maintenance to design and logistics.

Conclusion

In conclusion, bag making machines have evolved significantly since their inception, playing an essential role in modern manufacturing. As technology continues to advance and consumer preferences shift towards sustainability, these machines will undoubtedly adapt to meet new challenges. The future of bag making machines is promising, with innovations likely to drive further efficiency and environmental responsibility in the packaging industry. As we move forward, the significance of these machines in our daily lives will only grow, highlighting their importance in supporting both business operations and environmental sustainability.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025