bag closer machine parts

Understanding the Components of a Bag Closer Machine

In the modern era of packaging, efficiency and reliability are key components that businesses seek in their production lines. One of the unsung heroes of this process is the bag closer machine. This essential piece of equipment is responsible for sealing bags of various sizes and materials, ensuring that products remain secure during transportation and storage. To comprehend the functionality of a bag closer machine, it is essential to examine its key parts and how they work together to achieve optimal performance.

1. Sealing Mechanism

At the core of any bag closer machine is its sealing mechanism. Depending on the type of machine, this might involve sewing, heat sealing, or adhesive application. Sewing machines use a needle and thread to stitch the bag closed, making them particularly suitable for flexible and heavier materials. Heat sealing machines utilize heat to melt and bond plastic bags together, offering a quick and efficient method for sealing. Adhesive sealers, on the other hand, apply glue to the edges of the bag before they are pressed together, providing a strong and lasting seal.

2. Feed System

The feed system plays a crucial role in the operational efficiency of the bag closer machine. This system is designed to automatically position the bags for the sealing process. Many machines incorporate adjustable feed belts that can handle different bag sizes and materials, making it versatile for various applications. A consistent and reliable feed system minimizes downtime and ensures that the sealing process remains uninterrupted.

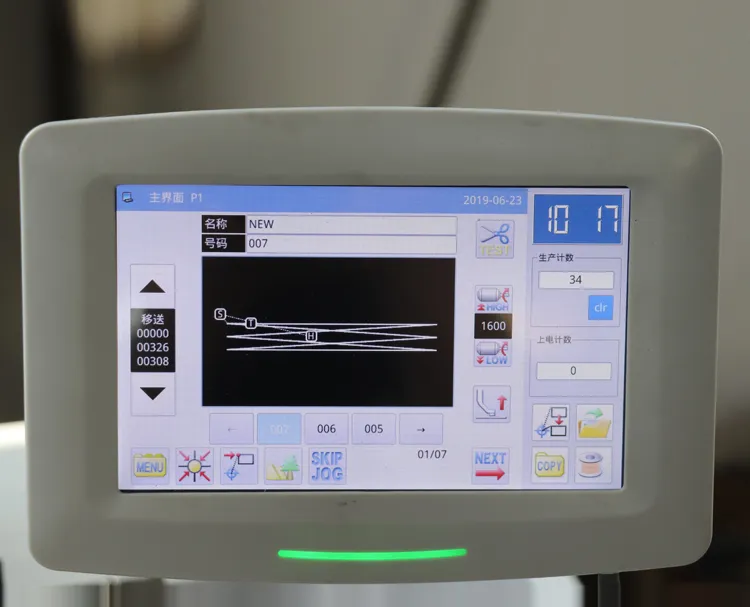

Modern bag closer machines come equipped with user-friendly control panels that enable operators to adjust settings with ease. The control panel allows users to set parameters such as sealing speed, temperature (in the case of heat sealers), and bag length. This adaptability ensures that the machine can handle diverse products and packaging requirements without sacrificing quality. Furthermore, advanced control systems may include programmable features that enable the machine to store settings for different bag types, enhancing efficiency in a high-volume production environment.

bag closer machine parts

4. Motor and Drive System

The motor is a pivotal aspect of the bag closer machine, powering the various components and ensuring smooth operation. The drive system connects the motor to the sealing mechanism and feed system, facilitating coordinated movement. High-quality motors that provide consistent torque are essential for maintaining efficiency and preventing mechanical failures, which can lead to costly downtimes. Many manufacturers now utilize energy-efficient motors, contributing to lower operational costs and a reduced environmental footprint.

5. Safety Features

Safety should always be a priority in any industrial setting, and bag closer machines are no exception. Most machines are designed with several safety features to protect the operator and the equipment. This may include emergency stop buttons, protective guards around moving parts, and sensors that prevent the machine from operating if the bags are not correctly positioned. These safety measures not only prevent accidents but also help to maintain product integrity throughout the sealing process.

6. Maintenance Components

Regular maintenance is essential to ensure the longevity and efficiency of a bag closer machine. Maintenance components such as lubrication systems for the moving parts, replaceable seals, and easily accessible cleaning areas are critical. A well-maintained machine reduces the likelihood of breakdowns and ensures that production continues smoothly.

In conclusion, a bag closer machine is a complex yet vital piece of equipment in packaging operations. Its various components work together cohesively to seal bags effectively, ensuring product safety and quality. By understanding the key parts of a bag closer machine, businesses can make informed decisions when selecting and maintaining their packaging equipment, ultimately enhancing their operational efficiency and product integrity. Whether it's sewing, sealing, or adhering, these machines are, without a doubt, an integral part of the packaging industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025