Feb . 18, 2025 08:12

Back to list

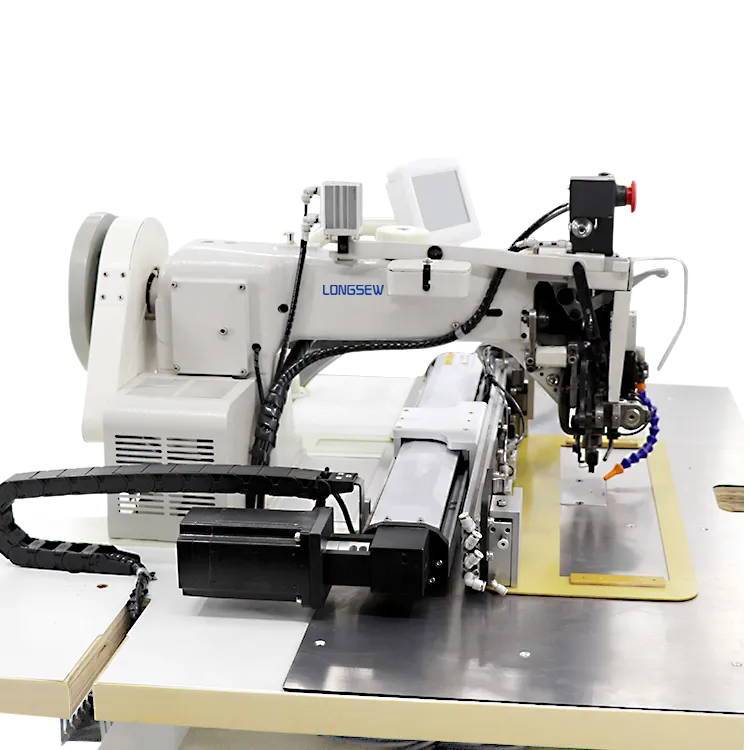

industrial sewing machine straight and zig zag

In the dynamic realm of garment manufacturing, understanding the nuances between different types of industrial sewing machines can significantly impact productivity and product quality. Among the myriad of sewing machinery available, the straight and zigzag industrial sewing machines stand out due to their versatility and widespread application.

Owning and operating these machines also requires a foundation of trust and expertise. As such, it is crucial to select machines from manufacturers known for their reliability and innovative engineering. Brands that offer substantial warranties and customer support tend to foster trust and ensure longevity in high-demand settings. Furthermore, empowering operators with ongoing training and skill development will enhance machine utilization. Skilled technicians adept in both straight and zigzag operations can dynamically switch roles as production demands shift, thus optimizing workforce flexibility. The strategic integration of these sewing machines into production lines can significantly affect competitive advantage in textile manufacturing. While the choice between machines depends on specific manufacturing needs, most operations find that a balance of both types provides the most comprehensive capabilities. Straight machines fulfill consistent, repetitive tasks, maintaining consistency, while zigzag machines allow for creative freedom and garment innovation. Evaluating manufacturer recommendations, user reviews, and industry standards also serves as a guide toward informed purchasing decisions. Investing in modern machines equipped with electronic controls for stitch length and tension adjustments further refines the production process. Consequently, these advancements contribute to elevated manufacturing standards, keeping companies at the forefront of the fashion and textile industry. The synergy between straight and zigzag industrial sewing machines ultimately represents a crucial determinant of business success. By leveraging their respective strengths, manufacturers can meet the varying demands of today’s market with precision, creativity, and reliability. Balancing cost-effectiveness with functionality enables producers to maintain a competitive edge while responding to ever-evolving fashion trends and consumer preferences.

Owning and operating these machines also requires a foundation of trust and expertise. As such, it is crucial to select machines from manufacturers known for their reliability and innovative engineering. Brands that offer substantial warranties and customer support tend to foster trust and ensure longevity in high-demand settings. Furthermore, empowering operators with ongoing training and skill development will enhance machine utilization. Skilled technicians adept in both straight and zigzag operations can dynamically switch roles as production demands shift, thus optimizing workforce flexibility. The strategic integration of these sewing machines into production lines can significantly affect competitive advantage in textile manufacturing. While the choice between machines depends on specific manufacturing needs, most operations find that a balance of both types provides the most comprehensive capabilities. Straight machines fulfill consistent, repetitive tasks, maintaining consistency, while zigzag machines allow for creative freedom and garment innovation. Evaluating manufacturer recommendations, user reviews, and industry standards also serves as a guide toward informed purchasing decisions. Investing in modern machines equipped with electronic controls for stitch length and tension adjustments further refines the production process. Consequently, these advancements contribute to elevated manufacturing standards, keeping companies at the forefront of the fashion and textile industry. The synergy between straight and zigzag industrial sewing machines ultimately represents a crucial determinant of business success. By leveraging their respective strengths, manufacturers can meet the varying demands of today’s market with precision, creativity, and reliability. Balancing cost-effectiveness with functionality enables producers to maintain a competitive edge while responding to ever-evolving fashion trends and consumer preferences.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025