Feb . 07, 2025 04:21

Back to list

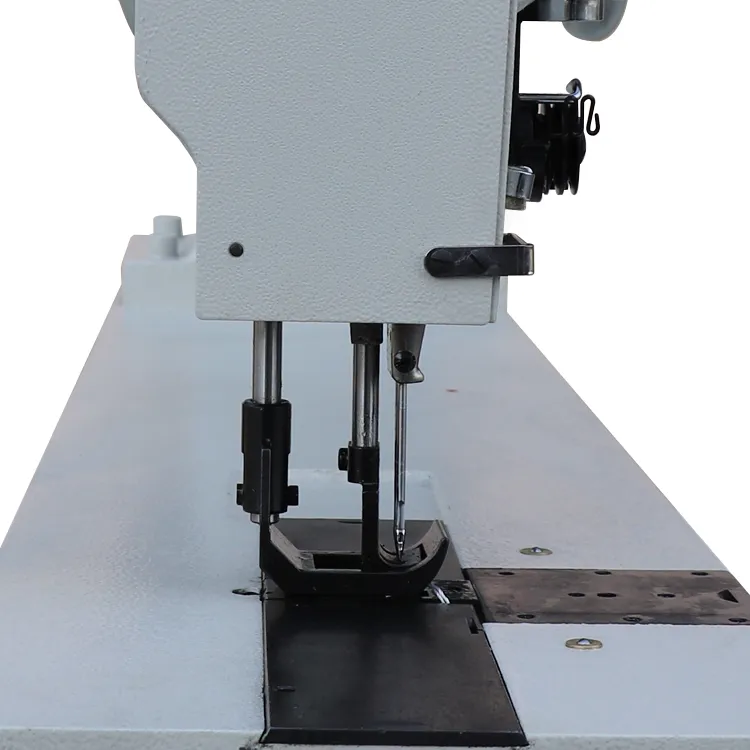

Long Arm Heavy Duty Single/Double Needles Compound Feed Flat Bed Sewing Machine JW-8BL30/JW-28BL30

The world of textile production is evolving at an unprecedented pace, with technological advancements redefining the landscape. One of the standout innovations in this field is the stitching automatic machine, a marvel that has revolutionized how garments are produced. For businesses invested in quality, efficiency, and innovation, understanding the nuances of these machines is crucial.

Investing in automatic stitching machines also aligns with the growing trend of sustainable manufacturing. These machines optimize fabric usage, thereby reducing waste—an ever-important consideration in today’s environmentally-conscious world. Fewer errors and higher precision translate to less material waste, further emphasizing the contribution of these machines toward sustainable production practices. The expert opinion in the industry corroborates the assertion that automatic stitching machines are not merely a trend but a necessity for forward-thinking textile manufacturers. Industry leaders recognize that beyond immediate benefits, the long-term gain in terms of operational efficiency, quality assurance, and brand reputation far outweighs the initial investment costs. Real-world experiences from manufacturers who have embraced these machines reveal significant improvements in delivery timelines and customer satisfaction. Trustworthiness in the industry is augmented when a company is perceived as adopting cutting-edge technologies that ensure high standards. Automatic stitching machines are a testament to a company's commitment to excellence. As these machines are built with state-of-the-art components by reputable manufacturers, they provide reliable performance and longevity. This reliability is critical not only in maintaining production schedules but also in ensuring continuous product quality, thus preserving the trust customers place in a brand. In conclusion, automatic stitching machines stand at the forefront of textile manufacturing innovation, signifying a merging of tradition and technology. As the textile industry continues to innovate, these machines are integral to maintaining a competitive advantage. With advantages spanning from operational excellence to enhanced sustainability practices, they are a valuable asset to any manufacturer keen on establishing itself as a leader in quality and efficiency. Therefore, for those ready to embrace technology and set a new benchmark in textile production, stitching automatic machines offer the perfect confluence of expertise, reliability, and innovation.

Investing in automatic stitching machines also aligns with the growing trend of sustainable manufacturing. These machines optimize fabric usage, thereby reducing waste—an ever-important consideration in today’s environmentally-conscious world. Fewer errors and higher precision translate to less material waste, further emphasizing the contribution of these machines toward sustainable production practices. The expert opinion in the industry corroborates the assertion that automatic stitching machines are not merely a trend but a necessity for forward-thinking textile manufacturers. Industry leaders recognize that beyond immediate benefits, the long-term gain in terms of operational efficiency, quality assurance, and brand reputation far outweighs the initial investment costs. Real-world experiences from manufacturers who have embraced these machines reveal significant improvements in delivery timelines and customer satisfaction. Trustworthiness in the industry is augmented when a company is perceived as adopting cutting-edge technologies that ensure high standards. Automatic stitching machines are a testament to a company's commitment to excellence. As these machines are built with state-of-the-art components by reputable manufacturers, they provide reliable performance and longevity. This reliability is critical not only in maintaining production schedules but also in ensuring continuous product quality, thus preserving the trust customers place in a brand. In conclusion, automatic stitching machines stand at the forefront of textile manufacturing innovation, signifying a merging of tradition and technology. As the textile industry continues to innovate, these machines are integral to maintaining a competitive advantage. With advantages spanning from operational excellence to enhanced sustainability practices, they are a valuable asset to any manufacturer keen on establishing itself as a leader in quality and efficiency. Therefore, for those ready to embrace technology and set a new benchmark in textile production, stitching automatic machines offer the perfect confluence of expertise, reliability, and innovation.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025