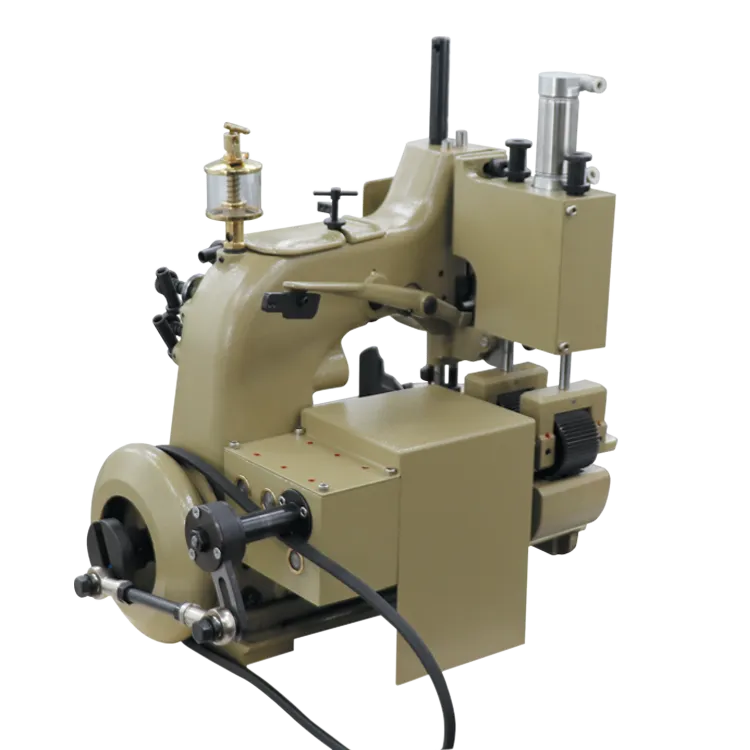

long arm & high arm sail making machine

The Long Arm and High Arm Sail Making Machine Revolutionizing the Sail Industry

The sailing industry, revered for its rich history and craftsmanship, has undergone significant transformations with technological advancements. Among these innovations, the long arm and high arm sail making machine has emerged as a pivotal tool, redefining efficiency, precision, and creativity in sail production.

The Evolution of Sail Making

Historically, sail making was an artisanal craft, characterized by meticulous handwork and traditional techniques passed down through generations. Sailmakers would spend countless hours measuring, cutting, and sewing fabric to create sails fit for various marine vessels. However, as sailing grew in popularity and the demand for high-quality sails surged, the limitations of manual techniques became evident. The industry necessitated a shift towards more efficient manufacturing processes.

Introduction to the Long Arm and High Arm Sail Making Machine

The long arm and high arm sail making machine was developed to address these challenges, combining advanced engineering with user-friendly design. Its long arm allows for the handling of large fabric pieces, providing the capability to create sails of various dimensions without the need for excessive manual labor. The high arm functionality enables the machine to sew multiple layers of heavy sail cloth, while also accommodating the thickness of different materials used in sail production.

Features and Benefits

long arm & high arm sail making machine

One of the standout features of the long arm and high arm sail making machine is its versatility. The machine can process a range of fabrics, including polyester, nylon, and Dacron, catering to diverse sailing needs, from recreational boats to professional racing yachts. This adaptability not only streamlines the manufacturing process but also enhances the quality of the final product.

Moreover, the machine boasts an impressive sewing speed, significantly reducing the time taken to complete a sail. Faster production times lead to quicker turnarounds for sailmakers, enabling them to meet customer demands more efficiently. Additionally, the precision with which these machines sew ensures that the seams are strong and durable, crucial for the safety and performance of sails in challenging marine environments.

Enhancing Skill and Creativity

While the long arm and high arm sail making machine automates many of the labor-intensive processes, it does not diminish the artistry involved in sail making. Instead, it allows skilled sailmakers to focus on creative aspects, such as customizing designs and patterns. With the machine handling the more tedious tasks, sailmakers can devote their time to innovating new sail designs that enhance aesthetics and functionality.

Furthermore, the integration of computer-aided design (CAD) technology with these machines has opened new avenues for precision and creativity. Sailmakers can now digitally draft their designs, allowing for intricate patterns and shapes that were previously difficult, if not impossible, to achieve manually.

Conclusion

The long arm and high arm sail making machine has undoubtedly revolutionized the sail industry, merging the best of traditional craftsmanship with modern technology. It empowers sailmakers to increase productivity while maintaining the quality and artistry that defines exceptional sail design. As the sailing community continues to evolve, this remarkable machine will remain at the forefront, shaping the future of sail making and contributing to the enduring legacy of sailing craftsmanship. With each passing year, as technology advances, the possibilities for innovation within the realm of sail making become limitless, promising a bright future for this storied craft.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025