Feb . 12, 2025 22:48

Back to list

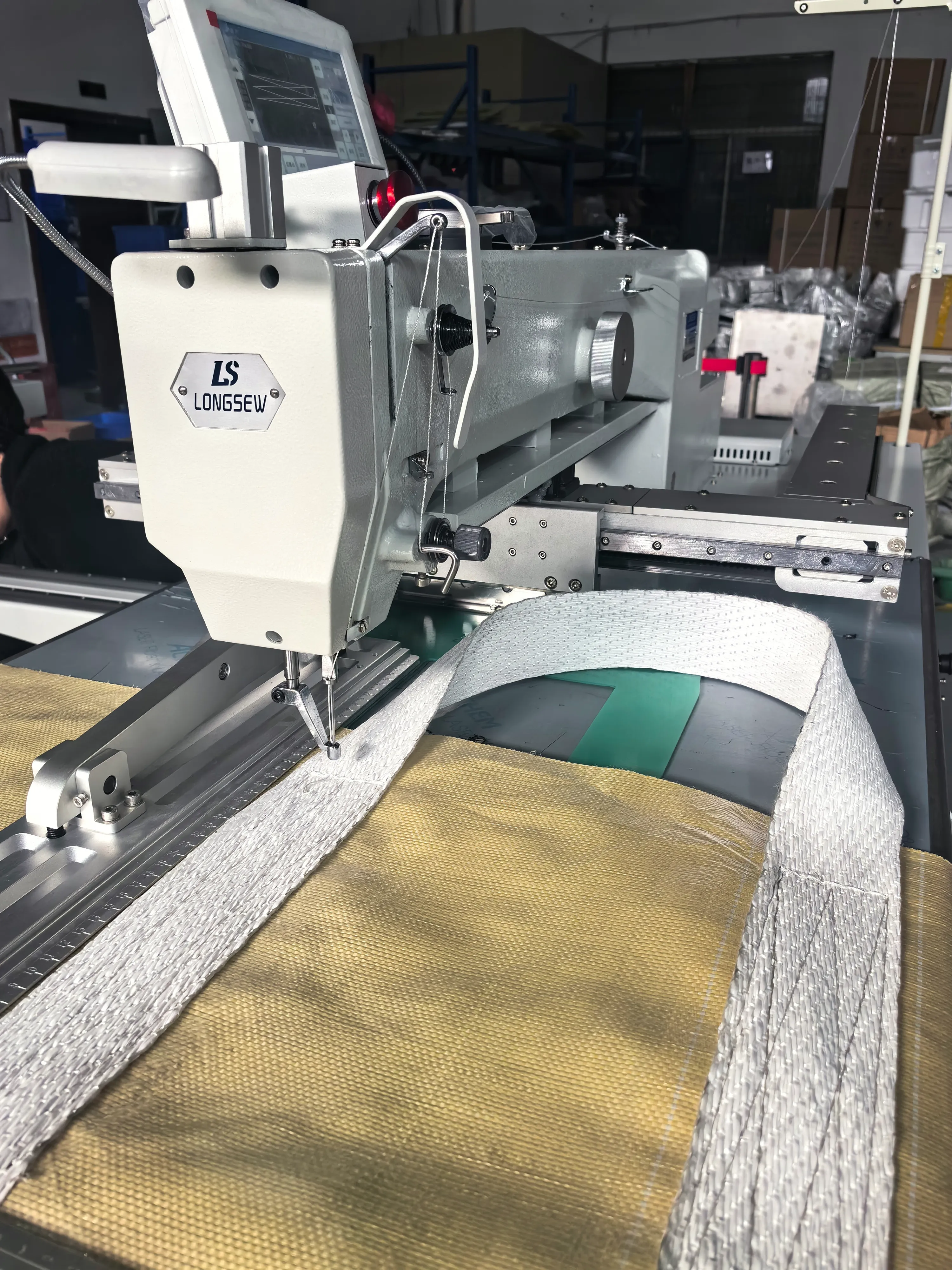

leather cylinder arm sewing machine

Understanding the pricing dynamics of leather machines can be both enlightening and complex, given the industrial and artisanal applications surrounding these devices. With a comprehensive grasp on real-world application, expert insights, authoritative resources, and trustworthy recommendations, you can navigate the market for leather machines more effectively.

Expert forums and leatherworking communities can offer insights into price trends and the practicality of various machines, fostering an environment where professionals can share experiences and recommendations. Whether through online platforms or industry conferences, engaging with industry experts provides an understanding of the realistic capabilities of different machines at varied price points. Furthermore, consulting reviews from authoritative leather industry publications or websites can offer a broader scope of knowledge. These sources often conduct thorough assessments, comparing the pros and cons of machines across price ranges. Such reviews can serve as a guiding resource, helping potential buyers identify which machines align best with their operational needs and budget constraints. Trustworthiness is another critical aspect as the leather machine market has numerous vendors and varying quality standards. Purchasing from reputable suppliers with proven track records ensures product integrity and after-sale reliability. Ensuring that the vendor offers a warranty can further protect your investment, as well as guarantee that you’re purchasing a genuine product. Finally, consider future-proofing your investment by contemplating emerging trends in leather manufacturing. As sustainability becomes prominent, machines capable of working with eco-friendly materials without compromising efficiency might present a forward-looking investment. Hence, the price tag, when paired with a machine’s ability to adapt to future industry shifts, becomes a key deciding factor. Navigating the price terrain of leather machines thus requires a synthesis of current industry practices, expert knowledge, and reliable vendor relationships. Understanding these facets not only helps make informed purchasing decisions but also maximizes the return on investment by aligning the chosen equipment with both present needs and future industry advancements.

Expert forums and leatherworking communities can offer insights into price trends and the practicality of various machines, fostering an environment where professionals can share experiences and recommendations. Whether through online platforms or industry conferences, engaging with industry experts provides an understanding of the realistic capabilities of different machines at varied price points. Furthermore, consulting reviews from authoritative leather industry publications or websites can offer a broader scope of knowledge. These sources often conduct thorough assessments, comparing the pros and cons of machines across price ranges. Such reviews can serve as a guiding resource, helping potential buyers identify which machines align best with their operational needs and budget constraints. Trustworthiness is another critical aspect as the leather machine market has numerous vendors and varying quality standards. Purchasing from reputable suppliers with proven track records ensures product integrity and after-sale reliability. Ensuring that the vendor offers a warranty can further protect your investment, as well as guarantee that you’re purchasing a genuine product. Finally, consider future-proofing your investment by contemplating emerging trends in leather manufacturing. As sustainability becomes prominent, machines capable of working with eco-friendly materials without compromising efficiency might present a forward-looking investment. Hence, the price tag, when paired with a machine’s ability to adapt to future industry shifts, becomes a key deciding factor. Navigating the price terrain of leather machines thus requires a synthesis of current industry practices, expert knowledge, and reliable vendor relationships. Understanding these facets not only helps make informed purchasing decisions but also maximizes the return on investment by aligning the chosen equipment with both present needs and future industry advancements.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025