Feb . 18, 2025 00:59

Back to list

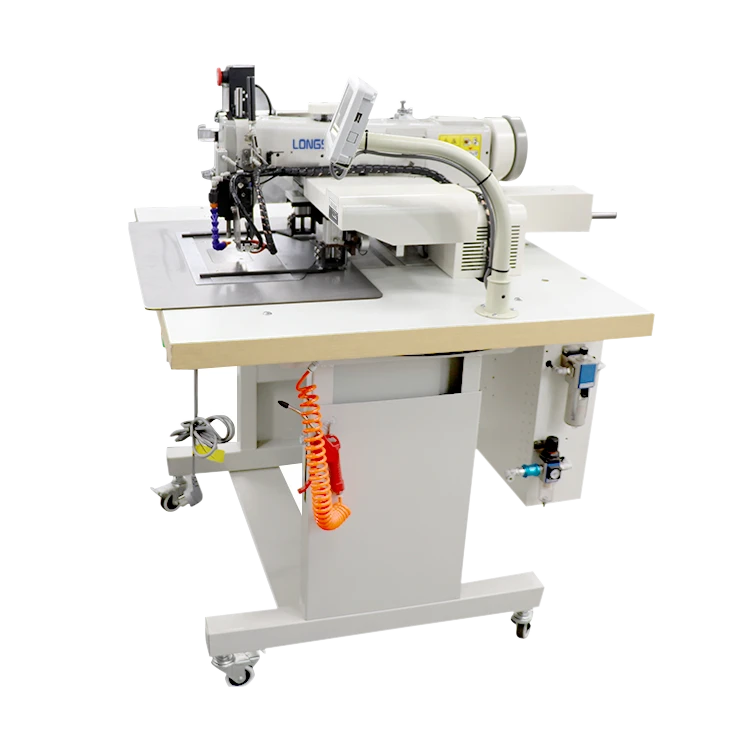

Heavy Duty Sail Bottom Feed 2,3,4 Steps Zigzag Sewing Machine LS366-32/LS366-32TD

Knit foot sewing machines are a revolutionary tool for both professional tailors and DIY enthusiasts. With the rising popularity of knit fabrics in both high fashion and everyday wear, investing in a sewing machine equipped with a knit foot can significantly enhance your sewing projects. These specialized machines cater to the unique properties of knit fabrics, ensuring precision, durability, and a professional finish that stands the test of time.

The authority of knit foot sewing machines doesn't solely rest in their functionality but extends to the creativity they unleash. With less concern for common knit fabric mishaps, users can venture into more complex projects, experimenting with innovative designs and unconventional patterns. This encouragement toward creativity is a testament to the machine’s design excellence, promoting not just efficiency but also artistic expression. Developing trust in a knit foot sewing machine involves acknowledging the engineering precision behind its creation. Brands renowned for their craftsmanship, such as Brother, Janome, and Singer, offer machines equipped with knit feet ensuring longevity and consistent performance. Reviews and user testimonials often highlight not just satisfaction, but loyalty, illustrating the machines’ role as an indispensable tool in the sewing room. Proper maintenance of the machine further builds user trust and extends its life. Regular cleaning, timely oiling, and correct storage are simple yet effective practices. Investing in a high-quality knit foot sewing machine loafs the potential for an incredible return in terms of project quality and personal growth in sewing expertise. These machines embody reliability, allowing users to focus on project execution and creativity rather than troubleshooting fabric issues. In sum, knit foot sewing machines are not just tools; they are gateways to a more enriched sewing experience. With their ability to transform the handling of knit fabrics from challenging to seamless, coupled with the satisfaction of producing professional-quality garments, these machines remain a worthy investment for anyone serious about sewing. Their presence in a sewing toolkit elevates the craft and inspires continued innovation and enjoyment in the creation of knit garments.

The authority of knit foot sewing machines doesn't solely rest in their functionality but extends to the creativity they unleash. With less concern for common knit fabric mishaps, users can venture into more complex projects, experimenting with innovative designs and unconventional patterns. This encouragement toward creativity is a testament to the machine’s design excellence, promoting not just efficiency but also artistic expression. Developing trust in a knit foot sewing machine involves acknowledging the engineering precision behind its creation. Brands renowned for their craftsmanship, such as Brother, Janome, and Singer, offer machines equipped with knit feet ensuring longevity and consistent performance. Reviews and user testimonials often highlight not just satisfaction, but loyalty, illustrating the machines’ role as an indispensable tool in the sewing room. Proper maintenance of the machine further builds user trust and extends its life. Regular cleaning, timely oiling, and correct storage are simple yet effective practices. Investing in a high-quality knit foot sewing machine loafs the potential for an incredible return in terms of project quality and personal growth in sewing expertise. These machines embody reliability, allowing users to focus on project execution and creativity rather than troubleshooting fabric issues. In sum, knit foot sewing machines are not just tools; they are gateways to a more enriched sewing experience. With their ability to transform the handling of knit fabrics from challenging to seamless, coupled with the satisfaction of producing professional-quality garments, these machines remain a worthy investment for anyone serious about sewing. Their presence in a sewing toolkit elevates the craft and inspires continued innovation and enjoyment in the creation of knit garments.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025