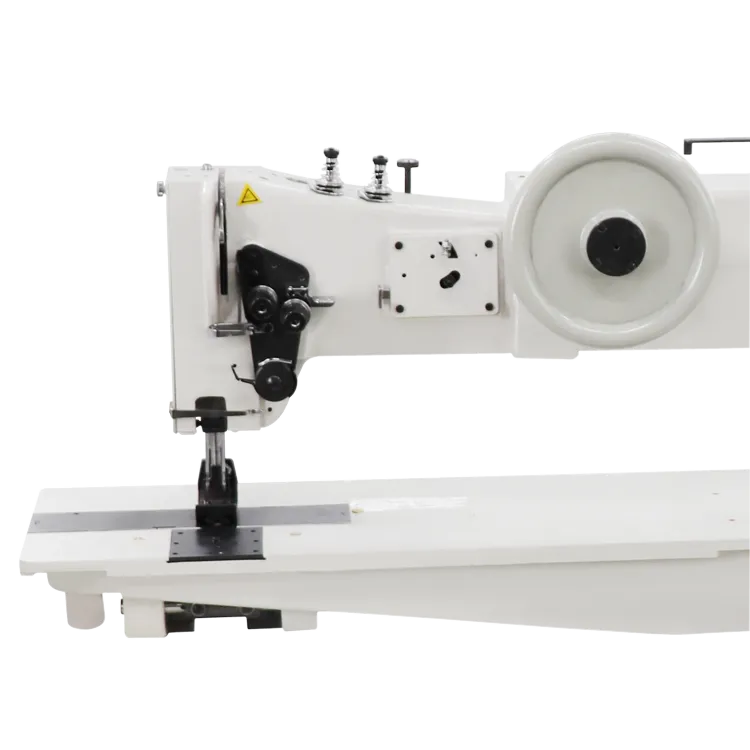

heavy industrial sewing machine

The Significance of Heavy Industrial Sewing Machines in Modern Manufacturing

Heavy industrial sewing machines play a crucial role in various sectors, particularly in the production of textiles and garments. These machines are specifically designed to handle thick materials and high-frequency operations, making them indispensable tools for manufacturers aiming to maintain efficiency and quality in their output. In this article, we will explore the functions, advantages, and impacts of heavy industrial sewing machines on the manufacturing landscape.

Understanding Heavy Industrial Sewing Machines

Heavy industrial sewing machines are robust and powerful equipment tailored for stitching together thick fabrics like leather, denim, canvas, and other industrial materials. Unlike standard sewing machines used for light textiles, heavy industrial sewing machines can withstand the rigors of high-speed operations, making them suitable for mass production environments.

These machines come equipped with specialized features such as walking feet, which allow for even feeding of tough materials, and high-torque motors that provide the necessary power to penetrate layers of fabric effortlessly. Additionally, many heavy industrial machines are designed for specific tasks, including zigzag stitching, straight stitching, or heavy-duty leatherwork, offering versatility to manufacturers.

Advantages of Heavy Industrial Sewing Machines

1. Durability and Longevity Built to endure the strain of continual use, heavy industrial sewing machines are constructed from high-quality materials that maximize their lifespan. This reliability makes them a worthy investment for manufacturers.

2. Increased Productivity These machines can operate at much higher speeds than conventional sewing machines, allowing for rapid production cycles. This efficiency is essential in meeting the demands of bulk orders and tight deadlines.

3. Quality of Stitching Heavy industrial sewing machines produce superior stitching quality, ensuring that seams are strong, even, and aesthetically pleasing. This quality is particularly important in the garment industry, where the durability of seams can impact the overall garment lifespan.

heavy industrial sewing machine

4. Versatility With various attachments and configurations available, heavy industrial machines can be adapted for a wide range of applications, from manufacturing uniforms and workwear to creating high-end fashion pieces.

5. Cost-effectiveness While the initial investment may be higher, the long-term savings achieved through durability, reduced maintenance costs, and increased productivity make heavy industrial sewing machines a cost-effective choice.

The Impact of Heavy Industrial Sewing Machines on Manufacturing

The effects of heavy industrial sewing machines extend beyond mere functionality. They have significantly influenced the textile and garment manufacturing sectors by enabling businesses to scale their operations while maintaining quality standards. As global demand for apparel rises, the capacity and speed provided by these machines have allowed manufacturers to meet market needs efficiently.

Moreover, heavy industrial sewing machines contribute to the global economy by creating job opportunities in manufacturing and related fields. Skilled operators are required to run these machines, fostering expertise and promoting workforce development in the textile industry.

The technological advancements accompanying heavy industrial sewing machines also cannot be understated. Automation and smart technology integration are paving the way for a new era in manufacturing, enhancing precision and control over production processes. This evolution not only boosts efficiency but also minimizes waste, promoting sustainable practices in the industry.

Conclusion

Heavy industrial sewing machines are integral to the evolution and success of modern manufacturing. Their ability to handle demanding tasks with efficiency and quality underlines their importance in producing a wide array of products, from everyday clothing to specialized industrial gear. As technology continues to advance, these machines will undoubtedly play an even more significant role in shaping the future of the textile industry, driving innovation, productivity, and sustainability. For manufacturers looking to thrive in a competitive market, investing in heavy industrial sewing machines is essential not only for enhancing output but also for maintaining the highest standards of craftsmanship in their products.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025