Industrial Heavy-Duty Sewing Machines for Robust and Reliable Fabric Work

The Heavy-Duty Sewing Machine A Cornerstone of Industrial Fabrication

In the world of textile production and industrial fabrication, the heavy-duty sewing machine stands out as an indispensable tool. Built to withstand rigorous use and equipped with features that cater to various heavy fabrics, these machines are designed for both efficiency and longevity. Understanding the significance of heavy-duty sewing machines can provide insights into their role in the manufacturing landscape.

Heavy-duty sewing machines are engineered to handle thick materials such as denim, leather, canvas, and upholstery fabrics. Traditional domestic sewing machines may falter when faced with such robust materials, but heavy-duty machines are equipped with stronger motors, reinforced frames, and specialized needles that enable them to sew through multiple layers without breaking down. This capability makes them essential in industries such as fashion, automotive, furniture, and outdoor gear manufacturing.

One of the key features of heavy-duty sewing machines is their powerful motor. Unlike regular sewing machines, which may have a motor that ranges from 0.5 to 1 amp, heavy-duty models can have motors that exceed 1.5 amps. This increased power allows for faster stitching speeds, often exceeding 1,000 stitches per minute. Consequently, manufacturers can significantly enhance their productivity while maintaining high-quality stitching standards.

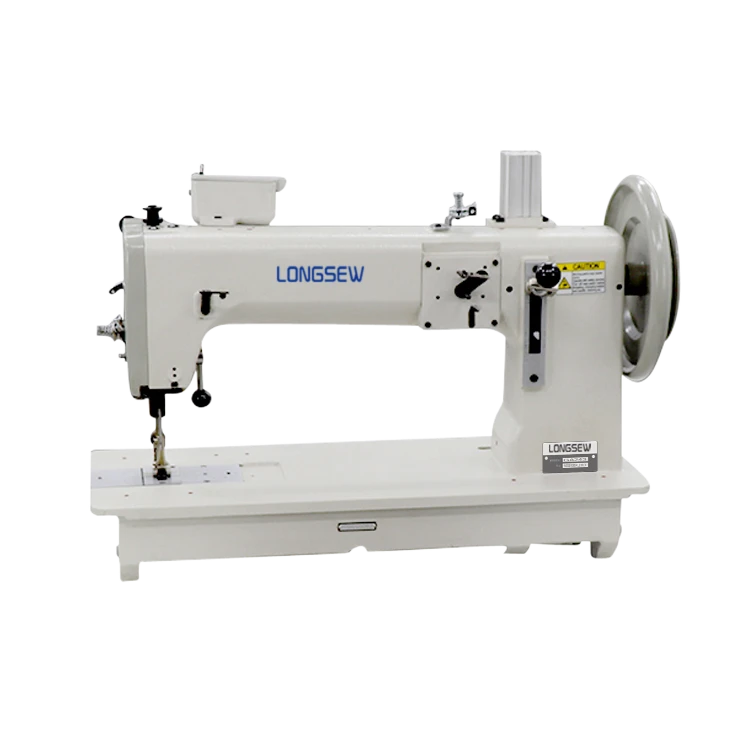

heavy duty sewing machine industrial

Durability is another hallmark of heavy-duty sewing machines. These machines are constructed with robust materials intended to endure years of demanding use. Features like all-metal bodies, heavy-duty presser feet, and advanced tension systems contribute to their resilience. When properly maintained, a heavy-duty sewing machine can serve its operator for a lifetime, making it a worthy investment for businesses.

Moreover, heavy-duty sewing machines often come with an array of functionalities that cater to the diverse needs of industrial sewing. Features such as adjustable stitch length and width, multiple sewing feet, and automatic needle positioning add versatility to the machine, allowing operators to tackle a wide range of sewing projects. This adaptability is crucial in a fast-paced industrial environment where demands can shift unpredictably.

In addition to functionality and durability, heavy-duty sewing machines contribute to cost savings for manufacturers. By facilitating faster and more efficient sewing processes, these machines help reduce labor costs and minimize material waste. The precise stitching they enable leads to higher-quality products that can enhance brand reputation and customer satisfaction.

In conclusion, the heavy-duty sewing machine plays a vital role in the industrial sector, transforming the way fabric is handled and stitched. With their ability to tackle tough materials, speed up production, and maintain high-quality outcomes, these machines are indispensable for businesses that prioritize efficiency and durability. As industries evolve and the demand for high-quality textile goods grows, the heavy-duty sewing machine will undoubtedly continue to be a cornerstone of industrial fabrication, empowering manufacturers to meet their goals and adapt to changing marketplace dynamics. Investing in a heavy-duty sewing machine is not just a choice for today; it’s a strategic move toward a sustainable and productive future in manufacturing.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025