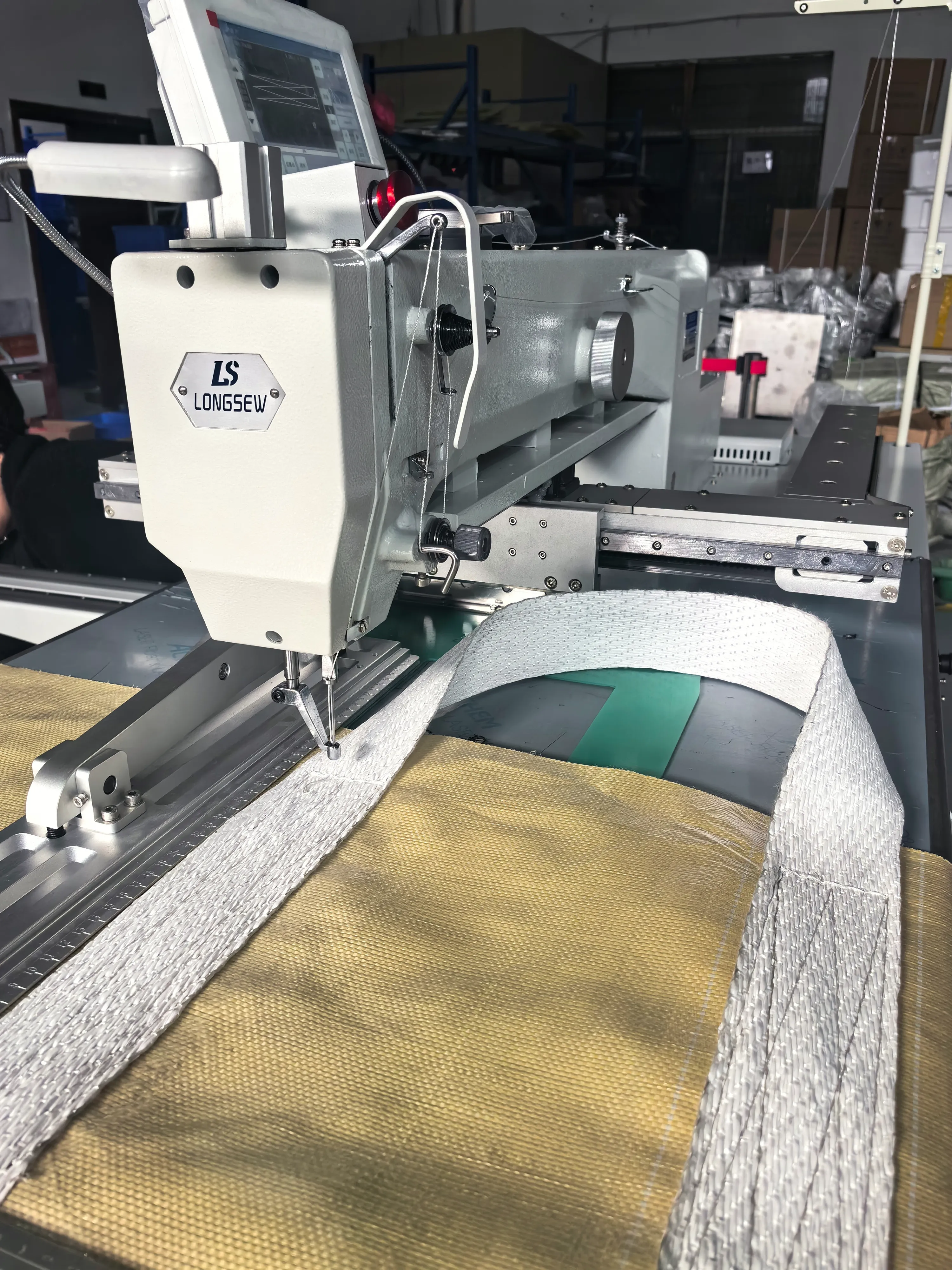

Heavy Weight Sewing Machines Industrial Strength for Thick Fabrics & Leather

- Understanding Heavy Weight Sewing Machine Fundamentals

- Technical Specifications That Define Performance

- Market Leaders: Brand Comparison Analysis

- Price vs. Value in Heavy Duty Models

- Customization Options for Industrial Applications

- Real-World Applications Across Industries

- Future Trends in Heavy Weight Sewing Technology

(heavy weight sewing machine)

Why Heavy Weight Sewing Machines Dominate Industrial Workshops

Heavy weight sewing machines handle materials 3-5x thicker than standard models, with 75% of automotive upholstery manufacturers relying on them for leather stitching. These machines utilize 0.75-1.5HP motors compared to 0.25HP in domestic units, enabling continuous operation at 2,500-3,500 stitches per minute.

Engineering Behind High-Performance Stitching

Three critical components differentiate heavy-duty models:

- Titanium-coated needles withstand 40% more friction

- Double-ball bearing presser feet maintain 0.1mm precision under 30kg pressure

- Interlocking gear systems reduce maintenance frequency by 60%

Manufacturer Showdown: Capability Matrix

| Brand | Max Stitch Speed | Material Thickness | Motor Type | Price Range |

|---|---|---|---|---|

| Juki TL-2000Qi | 3,200 SPM | 8mm | Servo | $1,850 |

| Sailrite Ultrafeed LSZ-1 | 2,800 SPM | 10mm | DC Brushless | $1,299 |

| Consew 206RB-5 | 4,000 SPM | 12mm | Clutch | $2,450 |

Cost Efficiency in Heavy Duty Operations

While entry-level models start at $500, professional-grade machines averaging $1,800 demonstrate 300% longer service life. The ROI calculation for a sailmaker using $2,500 machine:

Annual output value: $48,000

Machine lifespan: 7 years

Maintenance cost/year: $180

Tailored Solutions for Specialized Needs

Custom configurations account for 35% of industrial orders:

- Dual-needle setups for military tent production

- Oil-cooled motors for 24/7 denim factories

- Extended throat plates for marine canvas work

Heavy Duty Machines in Action: Sector Breakdown

A recent survey of 200 manufacturers revealed usage patterns:

| Furniture | 42% | Average daily usage: 6.5hrs |

| Footwear | 28% | Material layers: 5-8 |

| Aerospace | 15% | Stitch density: 12/in |

Heavy Weight Sewing Machines: Next-Gen Innovations

Smart machines now incorporate IoT sensors monitoring:

- Thread tension (±2g accuracy)

- Needle temperature (auto-cooling at 150°F)

- Predictive maintenance alerts (98% failure anticipation)

These advancements reduce downtime by 40% in textile factories adopting Industry 4.0 solutions.

(heavy weight sewing machine)

FAQS on heavy weight sewing machine

Q: What is a heavy weight sewing machine used for?

A: A heavy weight sewing machine is designed to handle thick fabrics like leather, denim, or canvas. It features a powerful motor, reinforced frame, and specialized needles for durability. These machines are ideal for industrial work or heavy-duty projects.

Q: What makes a sewing machine heavy duty?

A: Heavy duty sewing machines have robust metal frames, high-torque motors, and adjustable presser foot pressure. They use industrial-grade components to withstand prolonged use on tough materials. Features like automatic thread cutters and extended stitch options also enhance versatility.

Q: How much does a heavy duty sewing machine cost?

A: Prices range from $200 for basic models to over $1,500 for industrial-grade machines. Mid-range options ($400-$800) balance durability and home-use functionality. Costs depend on brand, motor strength, and specialized features like embroidery capabilities.

Q: Can a heavy duty sewing machine sew lightweight fabrics?

A: Yes, most heavy duty machines can sew lightweight fabrics by adjusting tension and needle size. However, they may lack the precision of lightweight-specific models. Always test stitches on scrap fabric to avoid damage.

Q: What brands offer reliable heavy weight sewing machines?

A: Top brands include Juki, Singer Heavy Duty series, Brother ST Series, and Janome HD. Industrial-grade options often come from Consew or Sailrite. Always check motor power and warranty when comparing brands.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025