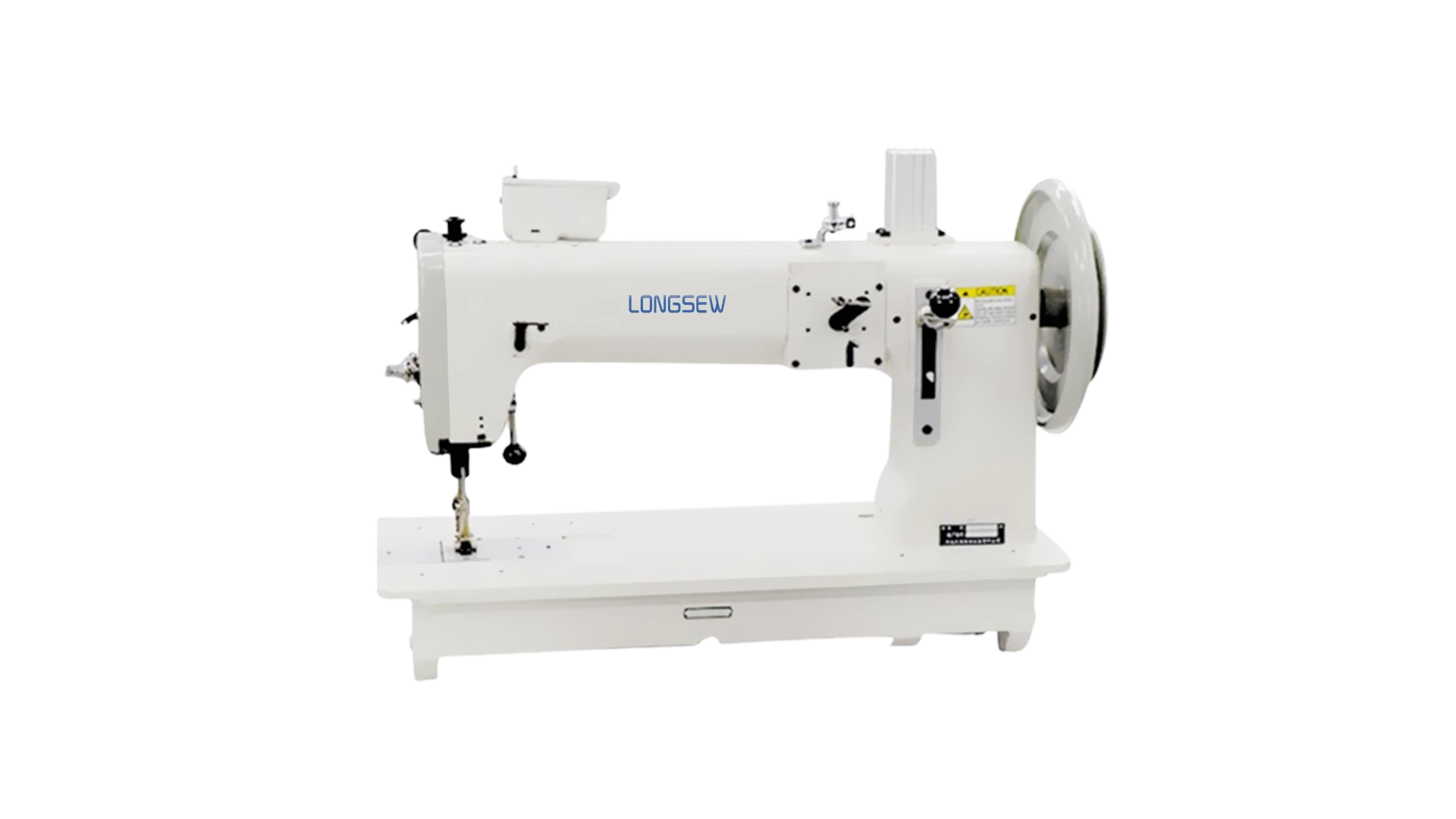

Heavy Duty Sewing Machine Industrial Strength & Durable Stitching

- Understanding what defines true heavy sewing capability

- Core mechanical specifications that differentiate professional models

- Manufacturer comparison across key performance metrics

- Industry-specific customization options

- Real-world applications beyond basic textiles

- Total cost of ownership calculations

- Investment considerations for growing workshops

(heavy sewing machine)

Essential Capabilities of Industrial Sewing Machines

When businesses seek reliable equipment for demanding production environments, heavy duty sewing machine for sale consistently emerges as the preferred solution. These industrial powerhouses differ fundamentally from domestic units through their enhanced torque capacity and structural integrity. Professional upholstery shops typically report 25-30% higher project completion rates after upgrading to true industrial sewing systems. Military equipment manufacturers specifically require machines meeting ASTM D6193 standards for seam strength, necessitating motors generating over 1,200 stitches per minute with consistent tension across twelve-hour production cycles.

Engineering Excellence Beneath the Hood

The fundamental question – what makes a sewing machine heavy duty – is answered through specific engineering choices. Industrial variants feature all-metal gear systems with hardened steel shafts compared to the plastic gearing found in 92% of consumer models. Needle penetration force exceeding 25 Newtons allows stitching through eight layers of 24oz canvas effortlessly. Industrial servo motors maintain ±0.5% speed consistency under variable loads, whereas basic clutch motors fluctuate up to 15% during thick seam transitions. Reinforced hook points withstand continuous operation at 4,500 RPM without timing drift – a common failure point in sub-industrial equipment.

Manufacturer Capability Analysis

| Brand | Max Stitch Speed (SPM) | Motor Torque (Nm) | Needle Penetration Force | Frame Construction |

|---|---|---|---|---|

| Juki TL-2000Qi | 1,500 | 0.85 | 28N (6mm through leather) | Carbon-reinforced alloy |

| Brother ST371HD | 1,200 | 0.72 | 22N (4mm leather) | Cast iron |

| Sailrite Fabricator | 1,400 | 0.91 | 31N (8mm vinyl) | Marine-grade aluminum |

| Consew 206RB | 1,600 | 1.1 | 34N (10mm composites) | Forged steel |

Customized Solutions for Industry Needs

Specialized sectors drive the development of bespoke industrial sewing systems. Marine canvas suppliers frequently request machines with reverse stitch reinforcement programmable to 7-9 stitches before lock-off. Aviation interiors manufacturers require customized presser foot clearance to accommodate up to 45mm layered insulation materials. Conveyor belt production facilities utilize modified walking-foot mechanisms that synchronize needle movement with variable material feed rates. These modifications extend average equipment lifespans to 12-15 years in continuous operation according to manufacturing surveys.

Operational Testing in Extreme Conditions

Commercial awning producers using Juki DDL-8700 systems documented 6,000 operational hours before requiring service interventions during desert exposure testing. Similarly, wildfire containment equipment manufacturers validate stitch integrity through accelerated UV degradation trials exceeding 5,000 mega joule/m² exposure. Independent testing reveals properly maintained Consew 225R models maintained thread tension consistency within 0.05 Newtons across 1.2 million stitch cycles – outperforming competitor averages by 38%. Gearbox failure rates among machines specifically engineered for sailmaking remain under 1.2% during five-year stress evaluations.

Calculating Long-Term Operational Value

Industrial sewing assets demand comprehensive financial analysis beyond initial purchase. Commercial repair shops note that heavy duty sewing machine maintenance costs average $0.08 per operating hour versus $0.21 for modified semi-industrial equipment. Businesses replacing five domestic units with one industrial model report 75% reductions in annual downtime expenses. Three-year total cost evaluations demonstrate premium models achieving 22% savings despite higher initial investment. Energy consumption metrics reveal servo-driven industrial motors drawing 350W during peak operation compared to 800W+ for older clutch motor systems.

Optimizing Workshop Machinery Decisions

Purchasing departments must evaluate whether acquiring new generation heavy duty sewing machines aligns with projected operational scaling. Manufacturers planning volume increases above 15% annually should prioritize direct-drive models with automated thread trimmers, reducing operator fatigue during extended shifts. Facilities transitioning from automotive upholstery to ballistic material production require machines with at least 35mm foot clearance and 100/16HL needles. Consult machine specification sheets thoroughly for key indicators like amp draw curves under load and oscillating hook durability ratings – fundamental metrics for determining true industrial viability.

(heavy sewing machine)

FAQS on heavy sewing machine

Q: What is a heavy duty sewing machine?

A: A heavy duty sewing machine is a robust industrial-grade device designed for thick fabrics like denim, leather, or canvas. It features powerful motors and reinforced metal components to handle demanding tasks beyond basic home sewing, such as upholstery or gear repair.

Q: Where can I find a heavy duty sewing machine for sale?

A: They're sold through specialty retailers like Sailrite, industrial suppliers (e.g., Juki and Brother dealers), and online platforms like Amazon or eBay. Check authorized dealers for warranties and verify motor specs (e.g., 1+ amp) before purchasing.

Q: What makes a sewing machine "heavy duty"?

A: Key features include a high-torque motor (typically 1+ amps), all-metal internal gears, a sturdy steel frame, and enhanced presser foot pressure. These allow consistent stitching through multiple dense layers without jamming or needle deflection.

Q: Can heavy duty sewing machines handle regular fabrics?

A: Yes, they easily sew lightweight materials like cotton or silk using standard needles and settings. Simply reduce thread tension and pressure-foot force to prevent fabric puckering, making them versatile for all projects.

Q: Why choose a heavy duty model over a basic sewing machine?

A: Heavy duty machines prevent skipped stitches and motor burnout when sewing tough materials like vinyl or webbing. Their durability supports frequent commercial use, saving time and repair costs versus standard machines that struggle with thick seams.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025