Heavy-Duty Sewing Machines Designed for Lifting Slings and Enhanced Durability in Industrial Applications

The Importance of Lifting Sling Sewing Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the role of technology cannot be overstated. One of the key advancements that has streamlined production processes is the lifting sling sewing machine. This specialized equipment is crucial in various industries, particularly in fabric and textiles, where it enhances efficiency and ensures high-quality output.

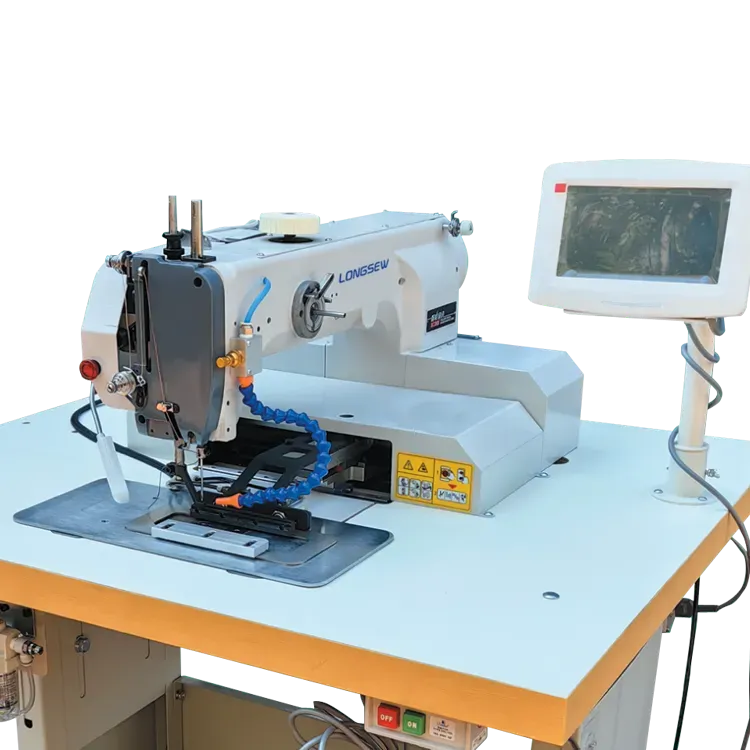

A lifting sling sewing machine is designed specifically to handle heavy-duty materials, making it ideal for sewing slings and other load-bearing devices. These machines are built with robust features that allow them to sew through thick and layered fabrics with precision. This is essential in industries such as construction, shipping, and logistics, where slings are used extensively to lift and transport goods safely.

One of the primary advantages of using a lifting sling sewing machine is its ability to improve productivity. Traditional sewing machines can struggle with heavy materials, leading to slower production times and increased wear and tear on both the machine and the operator. In contrast, lifting sling sewing machines are engineered to handle heavy loads efficiently, reducing downtime and accelerating the manufacturing process. Operators can complete more tasks in less time, ultimately contributing to higher output rates and improved profitability for businesses.

Additionally, the design and functionality of these machines ensure consistent quality in the finished product. Lifting sling sewing machines often incorporate advanced technology, such as computerized controls, which facilitate precise stitching and uniform tension. This consistent performance not only enhances the durability of the slings but also instills confidence among users regarding the safety and reliability of the products they use. In industries where safety is paramount, ensuring that every stitch is flawlessly executed can mean the difference between success and disaster.

lifting sling sewing machine

Moreover, the versatility of lifting sling sewing machines cannot be overlooked. They are capable of sewing a wide range of materials, including synthetic fibers, canvas, and webbing. This adaptability allows manufacturers to produce various types of slings—such as round slings, flat slings, and specialty slings—meeting diverse client needs. The ability to switch between different fabric types and sling designs without needing extensive downtime for machine adjustment enhances operational flexibility.

The automation feature often found in modern lifting sling sewing machines further bolsters efficiency. Automated stitching processes can minimize human error, ensuring that each sling is produced to the exact specifications required. With fewer mistakes, manufacturers can reduce material waste and minimize costs, leading to greater profitability. Furthermore, automation allows operators to focus on quality control and other critical tasks rather than being bogged down by repetitive sewing processes.

Training and safety are also significant considerations in the operation of lifting sling sewing machines. Manufacturers must ensure that their operators are well-trained in using these machines safely and effectively. Proper training not only enhances productivity but also minimizes the risk of accidents, which can have serious repercussions in a manufacturing environment. Safety protocols must be established to protect workers and ensure compliance with industry regulations.

In conclusion, the lifting sling sewing machine represents a vital component of modern manufacturing processes. Its ability to handle heavy materials with speed and precision, coupled with the advantages of automation and versatility, make it indispensable in producing high-quality slings for various industries. As manufacturing continues to advance, investing in advanced sewing technology will be essential for businesses looking to enhance productivity, ensure safety, and maintain a competitive edge in the marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025