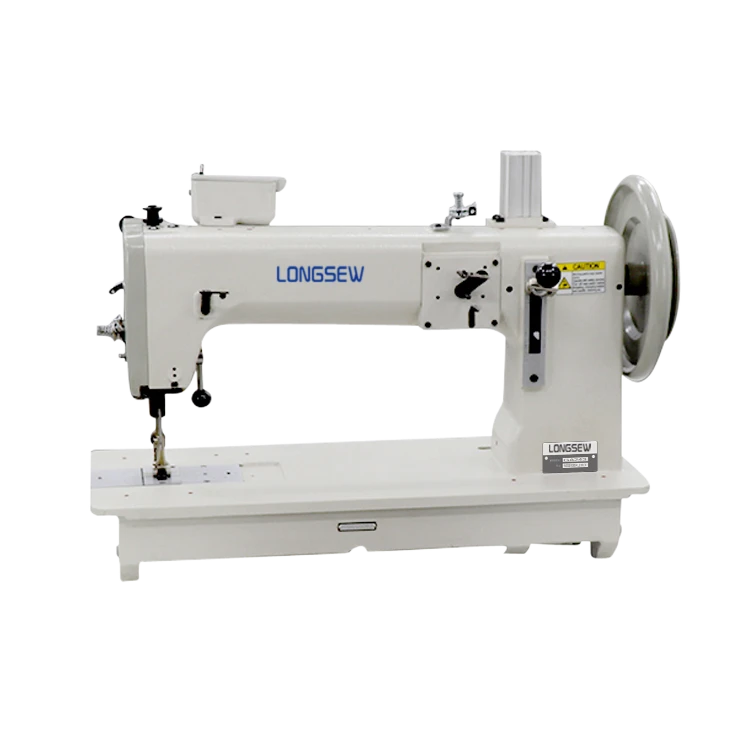

fibc overlock sewing machine

The Importance of FIBC Overlock Sewing Machines in Modern Manufacturing

In the rapidly evolving world of manufacturing and textile production, efficiency, durability, and precision are essential factors that determine the success of a business. One of the key players in achieving these goals is the FIBC (Flexible Intermediate Bulk Container) overlock sewing machine. This specialized equipment is designed to meet the growing demands of industries requiring robust and reliable packaging solutions, particularly in the transport of bulk materials.

The Importance of FIBC Overlock Sewing Machines in Modern Manufacturing

One of the primary advantages of using an FIBC overlock sewing machine is its efficiency. These machines can operate at high speeds, significantly increasing production rates compared to traditional sewing methods. This efficiency is particularly important in industries where time is money, and production delays can lead to substantial financial losses. An overlock sewing machine can handle heavy-duty materials, providing consistent quality in seam formation even when working with thick fabrics. This capability is instrumental in ensuring that FIBC bags meet industry standards concerning safety and performance.

fibc overlock sewing machine

Moreover, the precision offered by FIBC overlock sewing machines cannot be understated. With advanced technology and computer-controlled settings, these machines can create highly accurate seams that meet the stringent specifications required for heavy-load applications. The precise stitching ensures that the bags maintain their shape and integrity, which is essential for preventing spillage or damage to the contents. Furthermore, the machine's ability to adjust to different fabric types and thicknesses adds versatility, allowing manufacturers to produce a wide range of FIBC bags tailored to specific requirements.

Another significant aspect of FIBC overlock sewing machines is their ability to enhance sustainability in manufacturing processes. As industries increasingly focus on environmentally friendly practices, using high-quality sewing machines ensures that fewer bags fail during use, subsequently reducing waste. Durable FIBC bags that are properly sewn not only save costs over time but also lessen the environmental impact by minimizing the need for replacement bags. Additionally, many modern overlock sewing machines are designed to consume less energy, further contributing to sustainable manufacturing practices.

Integration of technology into the design of FIBC overlock sewing machines has led to improved user experience and operational safety. Features such as automatic threading, touch-screen controls, and safety sensors reduce the risk of operator error and enhance the overall efficiency of the sewing process. Operators are provided with more intuitive interfaces, leading to reduced training time and higher productivity levels.

In conclusion, FIBC overlock sewing machines are pivotal in modern manufacturing, particularly in producing strong, reliable, and efficient packaging solutions for bulk handling. Their efficiency, precision, and capacity to support sustainable practices make them an essential investment for businesses aiming to thrive in a competitive market. As industries continue to evolve, the role of FIBC overlock sewing machines will undoubtedly grow, reinforcing their importance in the textile and manufacturing sectors. By prioritizing quality and sustainability, manufacturers can ensure their operations remain efficient and successful in meeting customer demands.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025