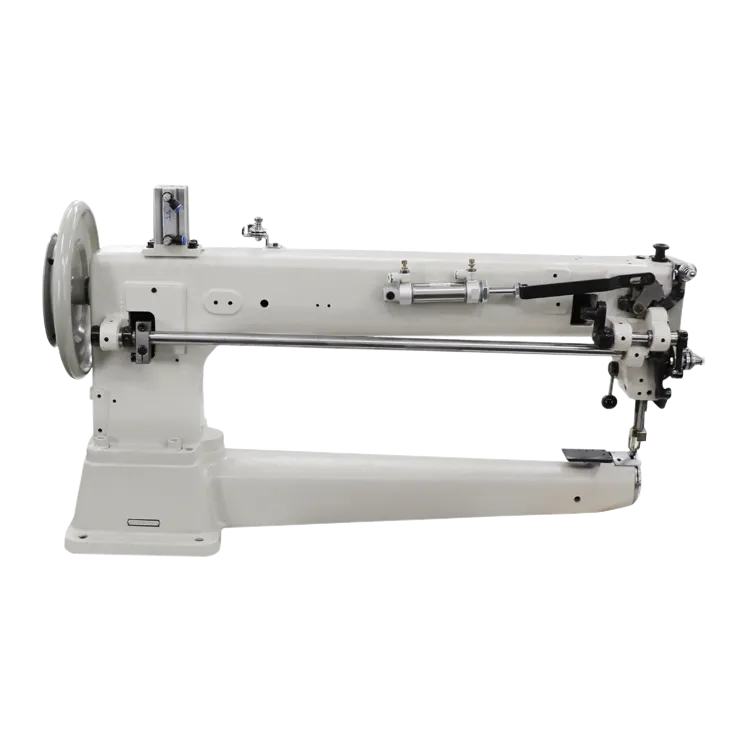

fibc bag shuttle hook sewing machine

The Importance of FIBC Bag Shuttle Hook Sewing Machines in Modern Packaging

In today's fast-paced industrial landscape, efficient packaging solutions are indispensable for the smooth operation of various sectors, including agriculture, construction, chemicals, and more. Among the myriad packaging options available, the Flexible Intermediate Bulk Container (FIBC) bags have gained immense popularity due to their durability and ease of use. The manufacturing of these bags requires specialized equipment, and one crucial component in this process is the FIBC bag shuttle hook sewing machine.

FIBC bags, often referred to as bulk bags, are designed to carry large quantities of material. They can hold anywhere from 500 to 2,000 kg of dry and flowable products, making them ideal for transporting substances like grains, sand, fertilizers, and chemicals. The demand for FIBC bags has surged, prompting manufacturers to invest in advanced sewing technology to ensure the production of high-quality bags that meet stringent industry standards.

The Importance of FIBC Bag Shuttle Hook Sewing Machines in Modern Packaging

One of the most significant advantages of using a shuttle hook sewing machine is its ability to create consistent, high-quality stitches at a faster rate compared to conventional machines. This efficiency is essential in a production environment where time equates to money. Manufacturers can keep up with high demand while maintaining the quality of their products. Furthermore, the machines are designed for ease of operation, minimizing the learning curve for workers and enhancing productivity across the board.

fibc bag shuttle hook sewing machine

Additionally, modern FIBC bag shuttle hook sewing machines come equipped with advanced technology, including programmable features that allow for customization of stitch patterns and lengths. This versatility enables manufacturers to produce various bag types tailored to specific customer requirements. Whether it's a bag with a duffle top, a spout bottom, or additional reinforcement, these machines have the capability to meet diverse needs.

Safety is another critical consideration in the production of FIBC bags. The shuttle hook sewing machine minimizes the risk of threading issues that could lead to defects in the bags, ensuring they are safe for transporting hazardous materials. Reliable stitching helps prevent leaks and spills, protecting both the product and the environment.

Moreover, with sustainability becoming an increasingly vital aspect of manufacturing, the use of efficient sewing machines contributes to reducing waste and improving production processes. High-quality stitching means less material is wasted on defective bags, promoting a more sustainable operation.

In conclusion, FIBC bag shuttle hook sewing machines play a pivotal role in the packaging industry. Their ability to produce high-quality, durable stitches quickly and reliably makes them an essential investment for manufacturers looking to meet growing consumer demands while adhering to safety standards. As industries continue to evolve, the role of innovative machinery like the shuttle hook sewing machine will only become more critical in ensuring efficiency and quality in the production of FIBC bags. By embracing these advanced technologies, manufacturers can not only enhance their productivity but also contribute to a more sustainable future in packaging solutions.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025