Optimizing the Production Line for FIBC Bag Manufacturing Efficiency

The FIBC Bag Producing Line Innovation in Bulk Packaging

In the ever-evolving world of packaging solutions, the Flexible Intermediate Bulk Container (FIBC) bag stands out as a versatile and efficient option for transporting a wide range of materials. As the demand for FIBC bags continues to rise, so does the need for efficient and innovative manufacturing processes. This is where the FIBC bag producing line comes into play, revolutionizing the way these essential packaging solutions are created.

Understanding FIBC Bags

FIBC bags, often referred to as bulk bags or big bags, are large flexible containers designed to hold and transport dry bulk materials. Commonly used in industries such as construction, agriculture, chemicals, and food, these bags offer several advantages, including high strength, lightweight construction, and cost-effectiveness. Their design allows for easy handling and stacking, making them a preferred choice for bulk material storage and transportation.

The FIBC Bag Producing Line Components and Process

The FIBC bag producing line is a sophisticated assembly of machinery and equipment that automates the manufacturing process of these bags. The production line typically includes several key components

1. Extrusion Machine The process begins with the extrusion machine, where raw polypropylene or polyethylene resin is melted and formed into flat film. This film serves as the primary material for the FIBC bags. The extruder ensures a consistent thickness and width of the material, which is crucial for the strength and durability of the final product.

2. Weaving Loom Once the film is produced, it is directed to the weaving loom, where the flat strips of film are woven into fabric. This fabric is the core structure of the FIBC bag. Advanced weaving techniques allow for a high degree of flexibility and strength, enabling the bags to hold heavy loads without tearing or bursting.

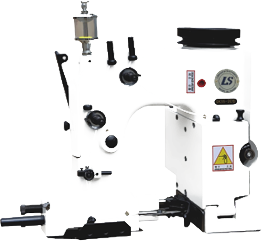

3. Cutting and Sewing After weaving, the fabric is cut into appropriate lengths for the bag dimensions. Skilled operators or automated sewing machines then stitch the fabric sections together to form the bag. This stage also includes the attachment of loops or lifting points, which are essential for handling the bags.

fibc bag producing line

4. Quality Control Quality assurance is a critical component of the FIBC bag producing line. Each bag is subjected to rigorous testing to ensure it meets industry standards for weight capacity, seam strength, and durability. This step is vital for maintaining the reputation of the manufacturer and ensuring customer satisfaction.

5. Printing and Customization Many manufacturers offer printing services for branding and labeling purposes. The printing processes can be integrated into the production line, allowing for customized designs to be applied directly to the bags before they are finished.

6. Final Touches and Packing Once the bags are sewn and printed, they undergo a final inspection before being folded and packed for shipping. Proper packing ensures that the bags reach their destination in pristine condition.

Advantages of an Automated Producing Line

Implementing an automated FIBC bag producing line brings numerous benefits. First, it significantly boosts production efficiency, allowing manufacturers to meet rising demand with consistent quality. Additionally, automation reduces labor costs and minimizes human error, resulting in a more reliable manufacturing process.

Furthermore, advanced technologies, such as computer-aided design (CAD) and industry 4.0 innovations, enable manufacturers to optimize their production lines. These technologies facilitate real-time monitoring and data analysis, leading to improved resource management and waste reduction.

The Future of FIBC Bag Production

As sustainability concerns grow, the FIBC bag industry is also evolving towards eco-friendly practices. Manufacturers are increasingly exploring biodegradable materials and recycling processes to produce environmentally friendly FIBC bags. Furthermore, innovations in production technology promise even greater efficiency and reduced environmental impact.

In conclusion, the FIBC bag producing line represents a crucial aspect of modern packaging manufacturing. By embracing advanced technology and streamlined processes, manufacturers can create high-quality FIBC bags that meet the diverse needs of various industries while ensuring environmental sustainability. This commitment to innovation will undoubtedly shape the future of bulk packaging solutions.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025