fibc bag producing line

The FIBC Bag Producing Line Revolutionizing Bulk Packaging Solutions

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, have become an essential component in various industries, including agriculture, construction, and pharmaceuticals. The demand for FIBC bags is escalating due to their ability to store and transport large quantities of materials efficiently. Key to this growing market is the innovative FIBC bag producing line, an advanced manufacturing solution that ensures the quality and consistency of these versatile containers.

The FIBC Bag Producing Line Revolutionizing Bulk Packaging Solutions

The next stage involves fabric weaving. This process is essential as it forms the basis of the bag’s structure. Modern production lines use high-speed weaving machines that not only increase efficiency but also maintain precision, ensuring that the fabric meets the necessary specifications. After weaving, the fabric is subjected to quality checks to verify its strength and longevity.

fibc bag producing line

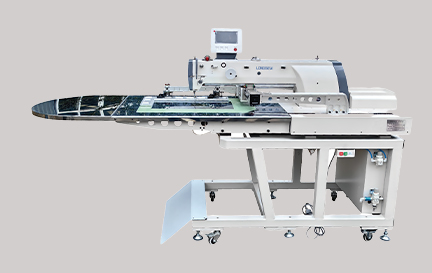

Following this, the fabric is cut to the required dimensions using automated cutting machines. Accurate cutting is vital for the uniformity of the bags and helps prevent material wastage. With cutting complete, the pieces are then sewn together using industrial sewing machines, which are capable of producing strong seams that can withstand the weight of heavy materials.

Once the seams are secure, the bags undergo additional processes such as printing and lamination. Custom printing allows manufacturers to brand their bags or indicate handling instructions, while lamination adds an extra layer of protection against moisture and contaminants. These finishing touches not only enhance the functionality of the bags but also improve their aesthetic appeal.

Finally, the completed FIBC bags are subjected to a rigorous quality control process. This includes checking for defects, measuring dimensions, and ensuring that each bag adheres to international safety standards. Once they pass inspection, the bags are packed and prepared for shipping, ready to meet the needs of a variety of industries.

In conclusion, the FIBC bag producing line represents a significant advancement in the realm of bulk packaging. By integrating automated systems and high-quality materials, manufacturers can produce durable, versatile bags that fulfill a range of applications. As industries continue to seek efficient packaging solutions, the importance of the FIBC bag producing line will only grow, solidifying its role as a cornerstone of modern manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025