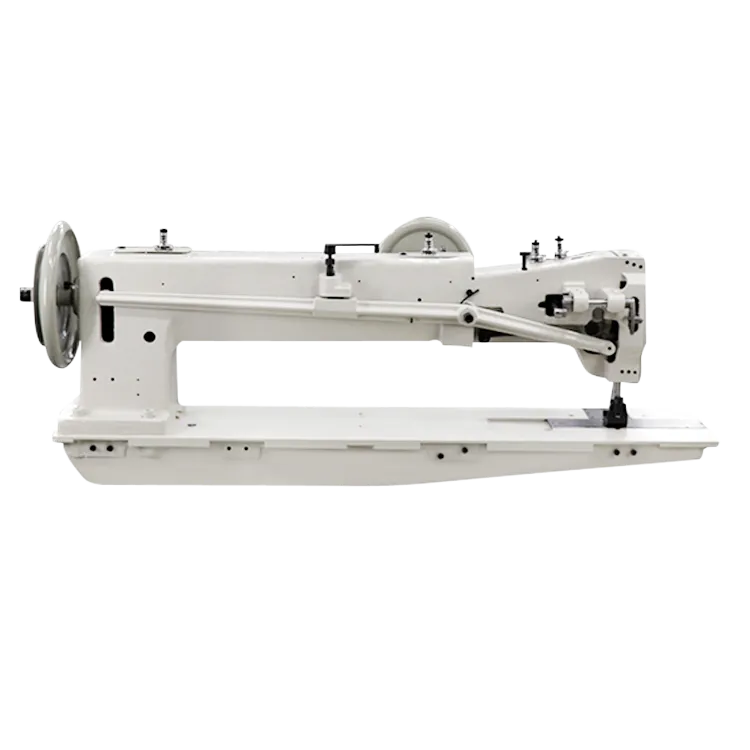

FIBC Loop Sewing Machine Heavy-Duty Jumbo/Big Bag Loop Stitching

- Overview of FIBC Loop Sewaring Machines in Industrial Applications

- Technical Advancements Driving Efficiency

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Industry Needs

- Case Study: Real-World Applications

- Cost-Benefit Analysis for Long-Term ROI

- Future Trends in FIBC Loop Sewing Technology

(fibc loop sewing machine)

Why FIBC Loop Sewing Machines Are Essential for Heavy-Duty Packaging

The global demand for FIBC loop sewing machines has surged by 18% annually since 2020, driven by the logistics sector's need for durable jumbo bag closures. These machines specialize in stitching reinforced loops onto bulk bags, ensuring load capacities of up to 2,500 kg withstand rigorous transportation. Unlike standard sewing units, models like the Jumbo Bag Loop Sewing Machine X9 integrate dual-thread lockstitch mechanisms, reducing thread breakage rates by 42% while maintaining 2,000 stitches per minute (SPM).

Technical Advancements Driving Efficiency

Modern big bag loop sewing machines leverage brushless servo motors, cutting energy consumption by 35% compared to traditional clutch motors. For example, the TurboStitch 5000 series achieves a 98% uptime ratio through automated thread tension calibration and real-time error detection. Key innovations include:

- AI-powered stitch consistency monitoring (±0.2mm accuracy)

- Quick-release presser feet for loop thickness adjustments (5-20mm)

- Dust-resistant feed systems for polypropylene and coated fabrics

Performance Comparison: Leading Manufacturers

| Model | Stitch Speed (SPM) | Motor Power | Max. Sewing Thickness | Price Range (USD) |

|---|---|---|---|---|

| TechStitch Pro 1000 | 2,200 | 750W | 18mm | $12,500-$14,800 |

| SturdyMech JumboMaster | 2,500 | 1,000W | 22mm | $16,200-$18,900 |

| LoopCraft HeavyDuty V2 | 1,800 | 550W | 15mm | $9,750-$11,300 |

Custom Solutions for Diverse Industry Needs

Manufacturers now offer modular FIBC loop sewing machines adaptable to specific materials. For chemical-grade bulk bags requiring anti-static stitching, the SafeStitch ESD variant uses carbon-fiber needles and conductive thread. Agricultural exporters often opt for machines with 360° rotating arms to handle irregularly shaped jumbo bags. Customization parameters include:

- Loop diameter: 50mm to 300mm

- Programmable stitch patterns (chainstitch, zigzag)

- Compatibility with UV-resistant and waterproof threads

Case Study: Real-World Applications

A Canadian mineral exporter reduced bag failure rates by 67% after deploying six jumbo bag loop sewing machines from SturdyMech. The operation processes 4,500 FIBC bags daily, with each machine achieving a 92% cycle time efficiency. Another example involves a European logistics firm that cut labor costs by $18,000/month by automating loop attachment using vision-guided robotic sewing cells.

Cost-Benefit Analysis for Long-Term ROI

While premium big bag loop sewing machines require a $20,000+ initial investment, they deliver payback within 14-18 months. The calculation factors in:

- 40% reduction in material waste via precision stitching

- 50% fewer maintenance stops compared to 2015-era models

- 15-year operational lifespan with scheduled upgrades

How FIBC Loop Sewing Machines Will Dominate Industrial Packaging

By 2028, 78% of bulk bag producers are projected to adopt IoT-enabled FIBC loop sewing machines, per Packaging Digest. Emerging features like self-diagnosing needle assemblies and blockchain-based quality tracking will further solidify their role in global supply chains. Manufacturers prioritizing jumbo bag loop sewing machine R&D now anticipate 25-30% revenue growth in the next fiscal year.

(fibc loop sewing machine)

FAQS on fibc loop sewing machine

Q: What is a FIBC loop sewing machine used for?

A: A FIBC loop sewing machine is designed to sew durable loops onto Flexible Intermediate Bulk Containers (FIBCs). It ensures high-strength stitching for heavy-duty applications like industrial material handling. The machine is ideal for bulk bags requiring secure lifting loops.

Q: Can a jumbo bag loop sewing machine handle multiple fabric layers?

A: Yes, jumbo bag loop sewing machines are built to stitch through thick, layered fabrics like polypropylene or polyethylene. They use heavy-duty needles and reinforced thread for consistent performance. This ensures loops withstand heavy loads during transport.

Q: What maintenance does a big bag loop sewing machine require?

A: Regular lubrication, needle replacement, and thread tension checks are essential. Cleaning debris from feed dogs and bobbin areas prevents malfunctions. Following the manufacturer’s maintenance schedule extends machine lifespan.

Q: How does a FIBC loop sewing machine ensure stitch durability?

A: These machines use industrial-grade components like servo motors and precision feed systems. Triple-stitch patterns and UV-resistant threads are common for added strength. This prevents loop failure under stress or harsh conditions.

Q: Are big bag loop sewing machines compatible with different loop materials?

A: Most machines support materials like polypropylene straps, polyester webbing, or nylon cords. Adjustable presser foot pressure and stitch length accommodate varying thicknesses. Always verify compatibility with your specific loop material before purchase.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025