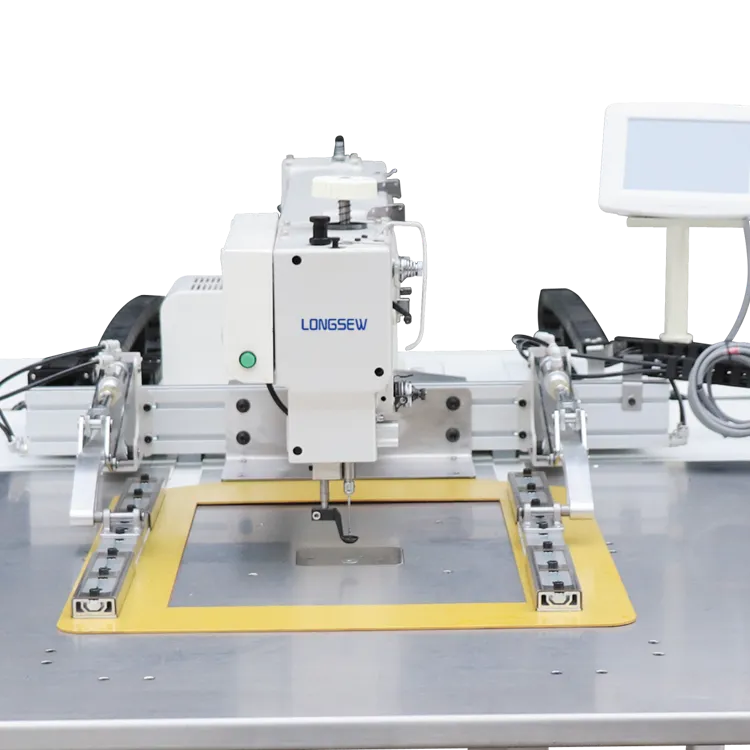

double needle bag closer machine

The Double Needle Bag Closer Machine An Essential Tool in Packaging

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. One of the often-overlooked heroes in the packaging industry is the double needle bag closer machine. This specialized equipment has become indispensable for businesses that require durability and reliability in their packaging processes.

What is a Double Needle Bag Closer Machine?

A double needle bag closer machine is a sewing device designed to close bags made from various materials such as polypropylene, jute, or paper. As the name suggests, it utilizes two needles to stitch the bag shut, creating a robust and secure closure. This machine is particularly useful in industries such as agriculture, food processing, and construction, where bags are commonly used to contain products like grains, fertilizers, or cement.

Advantages of Using a Double Needle Bag Closer Machine

One of the primary benefits of employing a double needle bag closer machine is its enhanced strength. The use of two needles ensures that the seams are tight and secure, significantly reducing the risk of bags opening during transport or storage. This added security not only protects the contents of the bags but also minimizes product loss, which can be a significant concern in many industries.

Another advantage is the speed and efficiency that these machines provide. Manual stitching can be labor-intensive and time-consuming. In contrast, a double needle bag closer machine can operate at high speeds, allowing businesses to process large quantities of bags in a fraction of the time. This efficiency can lead to increased productivity and reduced labor costs, giving businesses a competitive edge.

double needle bag closer machine

Versatility and Ease of Use

Double needle bag closer machines are versatile and can handle a variety of bag materials and sizes. This adaptability makes them suitable for numerous applications across different sectors. Moreover, modern machines are designed with user-friendly controls and features, enabling operators to quickly adjust settings for various bag types without extensive training.

The maintenance of a double needle bag closer machine is relatively straightforward, further enhancing its appeal for businesses. Routine checks and lubrication can keep the machine running smoothly and extend its lifespan, ensuring a worthwhile investment for manufacturers.

Sustainability Considerations

In an era where sustainability is becoming increasingly important, double needle bag closer machines can play a role in eco-friendly practices. By securely sealing bags, they can help reduce the amount of packaging waste generated from improperly closed bags. Additionally, many manufacturers are now producing machinery that is energy-efficient and designed with sustainable materials, aligning with corporate social responsibility goals.

Conclusion

In conclusion, the double needle bag closer machine stands out as an essential tool in the packaging industry. Its ability to provide strong, reliable closures while operating efficiently makes it invaluable for various sectors, from agriculture to construction. As businesses continue to seek ways to improve their processes and reduce waste, investing in a double needle bag closer machine is a step toward achieving these goals. As technology evolves, we can also anticipate advancements in this type of machinery, further enhancing its capabilities and sustainability in packaging.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025