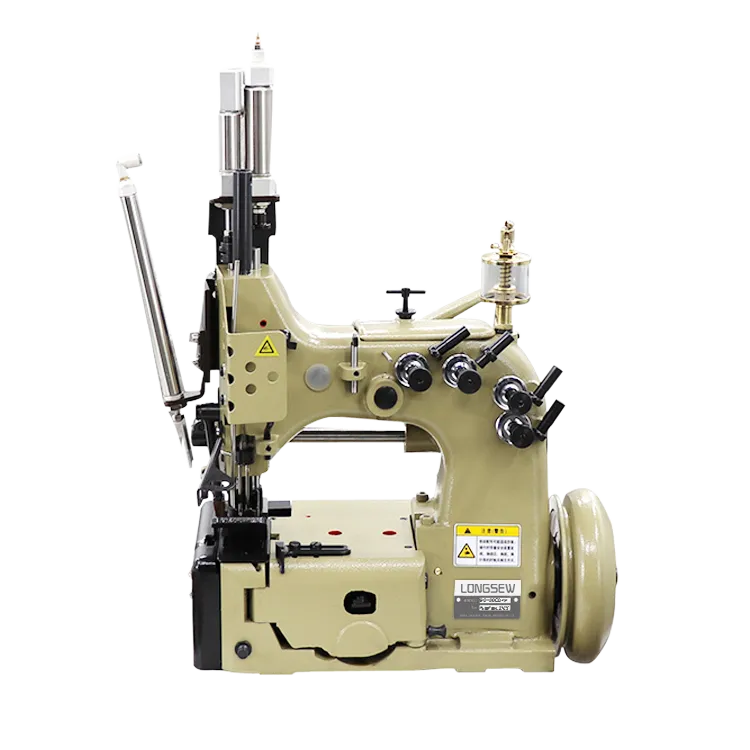

cylinder bed industrial sewing machine

The Versatility and Innovation of Cylinder Bed Industrial Sewing Machines

In the ever-evolving world of textile and garment manufacturing, the machinery used plays a pivotal role in determining the efficiency, quality, and scope of production. Among the myriad types of sewing machines available, the cylinder bed industrial sewing machine stands out for its unique capabilities and versatility, making it an indispensable tool in the industry.

Definition and Structure

A cylinder bed industrial sewing machine is designed with a cylindrical arm, which allows for easy maneuverability and access to hard-to-reach areas of garments. Unlike flat-bed machines, the cylinder bed configuration facilitates the sewing of tubular fabrics, such as sleeves, cuffs, and hems. This specific design is crucial for producing high-quality finished products in various sectors, including fashion, automotive upholstery, and marine textiles.

The construction of a cylinder bed sewing machine typically includes a sturdy base, a powerful motor, and advanced sewing technology. Many models are equipped with features that allow for various stitch types, automatic needle positioning, and programmable sewing patterns, thereby enhancing productivity and reducing the likelihood of human error.

Applications in the Industry

Cylinder bed industrial sewing machines are particularly favored in the production of garments that require precision and attention to detail. For instance, they are commonly used in the making of activewear, where the ability to sew stretch fabrics seamlessly is essential. The cylindrical arm allows operators to navigate around curved seams without compromising the integrity of the fabric.

In addition to apparel manufacturing, these machines are indispensable in the creation of technical textiles. Applications include sewing items such as bags, footwear, and even automotive interiors. The versatility of cylinder bed machines enables manufacturers to handle both lightweight and heavyweight materials, from delicate lace to robust canvas, thus broadening the product range that can be effectively produced.

cylinder bed industrial sewing machine

Advantages Over Other Sewing Machines

One of the primary advantages of cylinder bed sewing machines is their ability to handle tubular forms, which are commonly found in various garments. The cylindrical arm design minimizes the risk of fabric distortion that may occur with flat-bed machines, ensuring that seams remain straight and aligned. This characteristic is particularly important in industries where precision is critical, such as in the production of sportswear or specialized uniforms.

Moreover, the construction of cylinder bed machines often allows for greater needle visibility during operation. This is beneficial for operators striving for accuracy as they sew intricate patterns or delicate materials. The accessibility of the fabric under the needle, thanks to the cylindrical bed, contributes to greater control over the sewing process.

Technological Advancements

With the advancement of technology, modern cylinder bed industrial sewing machines come equipped with a variety of features that enhance their functionality. State-of-the-art models may include digital interfaces that allow users to program specific sewing tasks, memory functions that store patterns, and even automatic threading systems to minimize downtime.

Additionally, advancements in sewing automation and robotics can further optimize the production process. The integration of these technologies in cylinder bed sewing machines enables manufacturers to increase output while maintaining high-quality standards. Automated features can assist in repetitive tasks, freeing up skilled operators to focus on more complex sewing projects.

Conclusion

In conclusion, cylinder bed industrial sewing machines represent a significant innovation in the textile manufacturing sector. Their unique design, combined with the latest technological advancements, allows for unparalleled versatility and efficiency. As the demand for quality garments continues to rise, the relevance of these machines in boosting productivity and facilitating intricate designs becomes increasingly evident. With their ability to adapt to various materials and applications, cylinder bed sewing machines will undoubtedly remain a crucial component of the industrial sewing landscape for years to come. Manufacturers aiming to stay competitive must recognize the value of incorporating this specialized machinery into their production processes, ensuring they can meet market demands while upholding the standards of excellence that consumers expect.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025