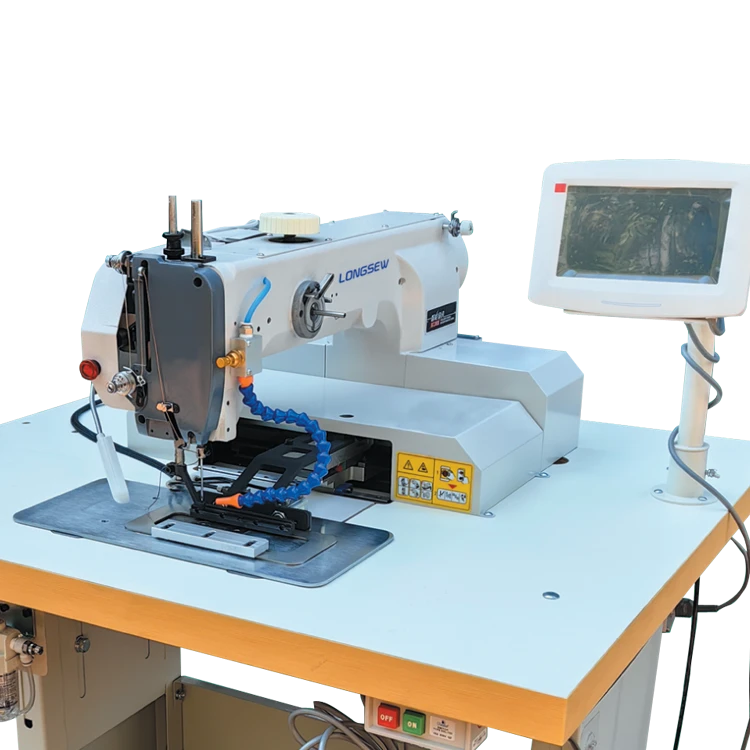

auto tailoring machine

The Evolution of Auto Tailoring Machines

In today’s fast-paced world, the fashion industry is no stranger to innovation and technological advancements. One of the most significant developments in this sector has been the emergence of auto tailoring machines. These cutting-edge devices have revolutionized the way garments are produced, making the process faster, more efficient, and increasingly precise.

Auto tailoring machines incorporate advanced technologies such as computer-aided design (CAD), automated cutting systems, and intelligent sewing mechanisms. This combination allows manufacturers to streamline their operations, reduce waste, and improve the quality of their products. The significance of these machines extends beyond mere convenience; they represent a paradigm shift in the garment production process.

Historically, tailoring was a labor-intensive craft that required considerable skill and time. Skilled tailors would spend hours measuring, cutting, and sewing fabric to create a single garment. The introduction of sewing machines in the 19th century marked the initial step towards automation, but it wasn't until the 21st century that auto tailoring machines began to truly transform the industry.

One of the core components of auto tailoring machines is the use of CAD software

. This technology allows designers to create detailed digital patterns that can be precisely replicated by the machines. With CAD, adjustments can be made quickly and efficiently, enabling designers to experiment with different styles and fits without the considerable lead time traditionally required. The ability to visualize the final product in a digital format also ensures that potential design flaws are identified before physical production begins.auto tailoring machine

Automated cutting systems have also played a vital role in enhancing the efficiency of garment production. These systems utilize high-precision cutting tools, often guided by lasers, to cut multiple layers of fabric simultaneously. This not only speeds up the cutting process but also minimizes fabric waste, an important consideration in an industry increasingly focused on sustainability. The precision of automated cutting machines ensures that each piece is cut to the exact specification, reducing the need for further adjustments during the sewing stage.

The sewing process has also benefited from automation through the development of intelligent sewing machines that can adapt to different materials and patterns. These machines can perform a wide variety of stitches and operations without the need for constant human intervention. By incorporating sensors and artificial intelligence, modern sewing machines can detect inconsistencies and adjust their operation on the fly. This smart adaptability results in higher quality garments and less material wastage.

Furthermore, auto tailoring machines cater to the growing demand for customization in the fashion market. As consumers increasingly seek unique, made-to-order items, the need for traditional, one-size-fits-all approaches diminishes. Auto tailoring machines can quickly adapt to individual measurements and preferences, allowing for a personalized experience that meets each customer’s specific requirements.

However, the rise of auto tailoring machines does raise questions about the future of the tailoring profession. While these technologies can significantly reduce the volume of human labor required, they also open up new opportunities for skilled workers. Tailors can transition from traditional garment-making roles to overseeing, programming, and maintaining auto tailoring machines, thereby integrating the art of tailoring with modern technology.

In conclusion, auto tailoring machines signify an exciting advancement in the fashion industry. They promise greater efficiency, higher quality production, and the potential for personalized fashion experiences. As the industry continues to evolve, embracing these technologies while honoring the craftsmanship and artistry of traditional tailoring will be crucial. The future of fashion is undoubtedly intertwined with automation, paving the way for innovative designs and sustainable practices that can cater to a dynamic consumer landscape.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025