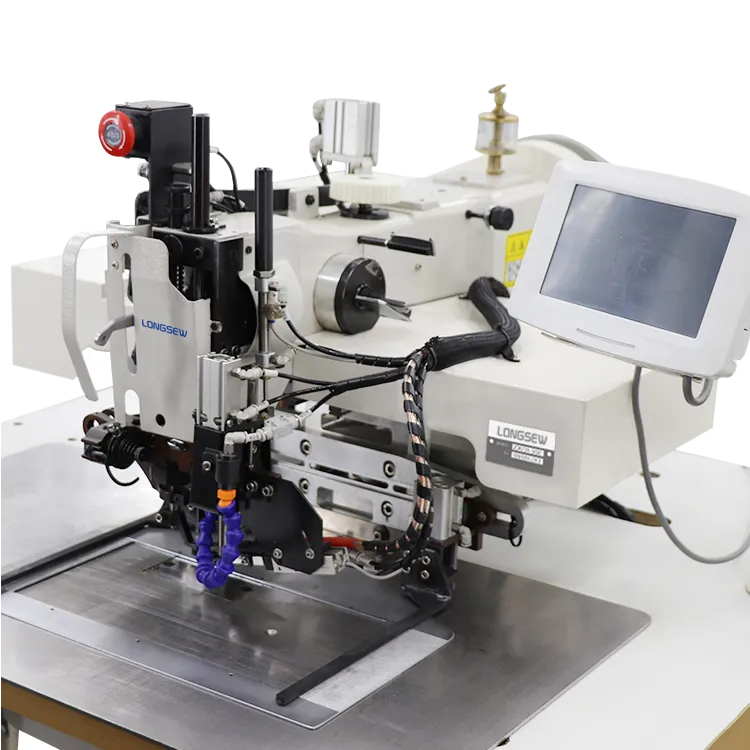

auto oil sewing machine

The Versatility of Auto Oil Sewing Machines

In the world of textile production, sewing machines play a pivotal role, acting as indispensable tools for both industrial and home applications. Among the various types of sewing machines, the auto oil sewing machine stands out due to its unique functionality and efficiency. This article delves into the characteristics, benefits, and applications of these machines, highlighting their importance in modern sewing operations.

Understanding Auto Oil Sewing Machines

Auto oil sewing machines are equipped with an automatic lubrication system that ensures seamless operation. Unlike traditional sewing machines that require manual oiling, these advanced machines use a built-in mechanism to deliver lubricant to the necessary components at regular intervals. This innovative feature not only enhances the machine's performance but also extends its lifespan, making it an ideal choice for high-volume sewing tasks.

The auto oiling system typically consists of an oil reservoir, tubing, and lubrication points strategically placed throughout the machine. As the sewing machine operates, oil is circulated automatically, reducing friction between moving parts. This automatic lubrication not only minimizes wear and tear on the machine but also helps in maintaining optimal sewing speed and stitch quality.

Advantages of Auto Oil Sewing Machines

1. Increased Productivity One of the most significant advantages of auto oil sewing machines is their ability to boost productivity. With the automatic lubrication system in place, operators can focus on their sewing tasks without the need for frequent interruptions to oil the machine. This results in higher output, especially in industrial settings where time is of the essence.

2. Consistency in Stitch Quality A well-oiled machine produces more consistent and high-quality stitches. The automatic oiling system ensures that all moving parts are adequately lubricated, preventing issues such as thread breakage and uneven stitching. This consistency is crucial for manufacturers who need to deliver flawless products to their customers.

3. Reduced Maintenance Costs Manual oiling can often lead to inconsistent lubrication, resulting in increased wear and tear on the machine. Auto oil sewing machines mitigate this risk, reducing the need for frequent maintenance and replacement parts. This not only lowers maintenance costs but also enhances the overall reliability of the equipment.

auto oil sewing machine

4. User-Friendly Operation For operators, the user-friendly nature of auto oil sewing machines is a significant benefit. The elimination of manual oiling means less hassle, allowing even novice users to operate the machine with ease. This accessibility makes it an attractive option for small businesses and home sewers who may not have extensive experience with sewing equipment.

Applications of Auto Oil Sewing Machines

Auto oil sewing machines are used in a variety of applications across different industries. Their versatility makes them suitable for

- Apparel Manufacturing In the fashion industry, where precision and speed are paramount, auto oil machines are essential for mass production. They ensure that garments are stitched quickly and impeccably, meeting the demands of fast-paced fashion cycles.

- Upholstery and Home Décor For businesses specializing in upholstery and home furnishings, these machines offer the durability and efficiency required for heavy fabrics. The auto oil feature helps maintain consistent performance even when sewing through multiple layers of material.

- Leather Goods Production Leather crafting requires specialized equipment, and auto oil sewing machines are well-suited for this task. The robust lubrication system allows for smooth operation on thick and tough materials, ensuring high-quality stitches that are durable and aesthetically pleasing.

- Automotive and Marine Industries These machines are also increasingly being utilized in automotive and marine industries for sewing heavy-duty materials, such as canvas and vinyl. The ability to work with tough fabrics makes auto oil sewing machines a valuable asset in these sectors.

Conclusion

In conclusion, auto oil sewing machines represent a significant advancement in sewing technology, combining efficiency with user-friendly operation. Their automatic lubrication systems not only improve productivity and stitch quality but also reduce maintenance costs, making them an excellent investment for businesses and individual users alike. As industries continue to evolve, the role of such machines will likely expand, solidifying their place as essential equipment in various applications across the textile world. Whether in a factory or a home workshop, auto oil sewing machines are here to revolutionize the way we sew and create.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025