Feb . 02, 2025 05:03

Back to list

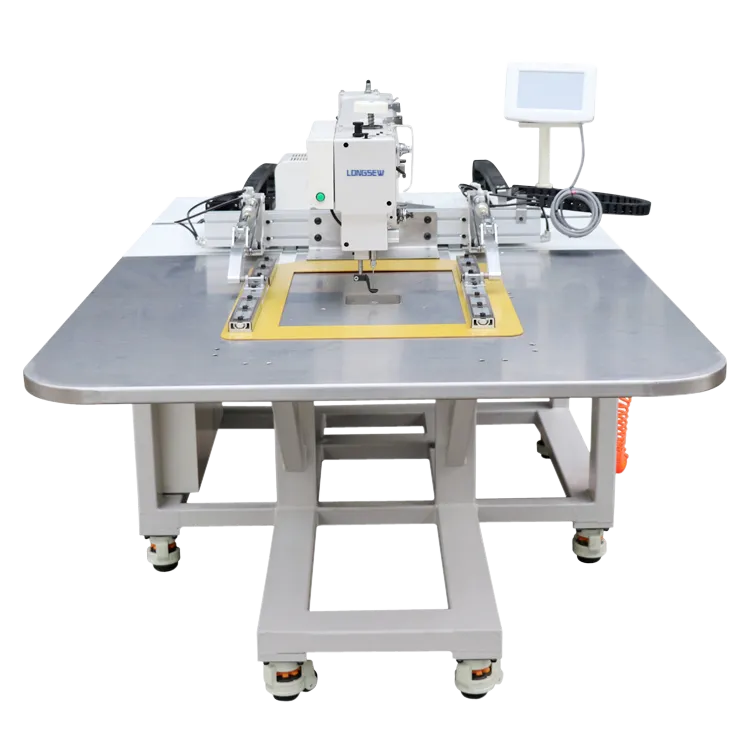

Heavy Duty Computerized Auto Pattern Sewing Machine For Safety Rope or Safety Belt LS273-2010H / LS273-2010S

Navigating the complex landscape of automotive upholstery requires not only a keen eye for design but also the right equipment to bring those visions to life. Among the essential tools in this craft is the automotive upholstery sewing machine—a device that plays a pivotal role in ensuring that every stitch is both functional and aesthetically pleasing. This article delves into the intricacies of selecting, using, and maintaining a top-tier automotive upholstery sewing machine, promising an unrivaled journey into the heart of automotive interior craftsmanship.

Moreover, needle size and type are pivotal in ensuring superior results. Leather needles, with cutting points, make transpiring through tough materials seamless, while ballpoint needles are preferable for knitting fabrics. Professionals emphasize the importance of regularly replacing needles, as dull ones can compromise stitch quality and damage the material. Regular maintenance is another aspect that cannot be ignored if one is to uphold the integrity and longevity of an upholstery sewing machine. Simple practices such as cleaning lint buildup, oiling, and scheduled servicing protect moving parts from wear and tear. Users have reported that consistent maintenance not only extends the machine's life but also maintains optimal performance, reducing costly downtimes. Trustworthiness in the selection of a sewing machine also emanates from the provision of after-sales support and warranty services. Brands that offer comprehensive customer service and facilitate easy access to replacement parts invariably build a loyal clientele. Testimonials underscore that responsive technical support often makes the difference between prolonged projects and timely job completions. Among practitioners, the seamless blending of skills and machinery is likened to a symphony; it requires harmony. The marriage of technique and technology propels the craft of automotive upholstery to new heights, enabling artisans to transform mundane vehicle interiors into bespoke environments of luxury and comfort. In conclusion, selecting the right automotive upholstery sewing machine is both an art and a science. It rests upon a foundation of real-world experiences, technical expertise, authoritative knowledge of available options, and results-driven trustworthiness. As the automotive industry evolves, demanding bespoke and intricate designs, so too must the tools of the trade adapt. The future of automotive upholstery is bright, with innovative machines leading the charge, seamlessly blending functionality with form to elevate the driving experience into an art form.

Moreover, needle size and type are pivotal in ensuring superior results. Leather needles, with cutting points, make transpiring through tough materials seamless, while ballpoint needles are preferable for knitting fabrics. Professionals emphasize the importance of regularly replacing needles, as dull ones can compromise stitch quality and damage the material. Regular maintenance is another aspect that cannot be ignored if one is to uphold the integrity and longevity of an upholstery sewing machine. Simple practices such as cleaning lint buildup, oiling, and scheduled servicing protect moving parts from wear and tear. Users have reported that consistent maintenance not only extends the machine's life but also maintains optimal performance, reducing costly downtimes. Trustworthiness in the selection of a sewing machine also emanates from the provision of after-sales support and warranty services. Brands that offer comprehensive customer service and facilitate easy access to replacement parts invariably build a loyal clientele. Testimonials underscore that responsive technical support often makes the difference between prolonged projects and timely job completions. Among practitioners, the seamless blending of skills and machinery is likened to a symphony; it requires harmony. The marriage of technique and technology propels the craft of automotive upholstery to new heights, enabling artisans to transform mundane vehicle interiors into bespoke environments of luxury and comfort. In conclusion, selecting the right automotive upholstery sewing machine is both an art and a science. It rests upon a foundation of real-world experiences, technical expertise, authoritative knowledge of available options, and results-driven trustworthiness. As the automotive industry evolves, demanding bespoke and intricate designs, so too must the tools of the trade adapt. The future of automotive upholstery is bright, with innovative machines leading the charge, seamlessly blending functionality with form to elevate the driving experience into an art form.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025