Exploring the Advancements in Automatic Machine Sewing Technology for Modern Tailoring Solutions

The Evolution and Impact of Automatic Machine Sewing

In the realm of textile and garment production, automatic machine sewing stands as a monumental innovation that has significantly transformed the industry. From its modest beginnings in the early 19th century to the sophisticated, computerized systems of today, automatic machine sewing has not only enhanced productivity but has also revolutionized the way garments are designed and manufactured.

Historical Context

The journey of automatic machine sewing began with the invention of the sewing machine by Elias Howe in 1846 and later refined by Isaac Singer. These early machines mechanized the sewing process, enabling faster production than hand sewing. However, the advent of automatic sewing machines came later, in the 20th century, with the integration of electric motors and programmable systems. This shift allowed for increased efficiency, consistency, and accuracy, marking a turning point in the fashion and textile industries.

Technology and Functionality

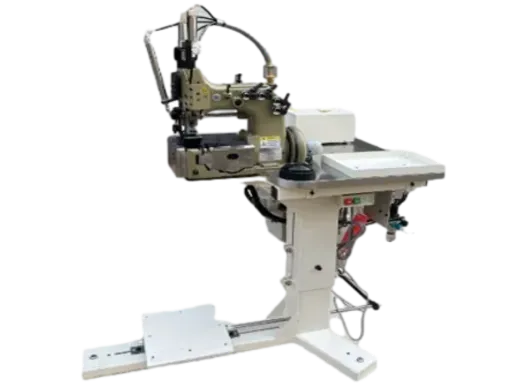

Today’s automatic sewing machines incorporate advanced technologies such as computerization and robotics. These machines can perform a wide array of tasks—from simple straight stitches to complex embroidery—often at speeds surpassing those of human workers. Modern automatic sewing machines are equipped with tools like sensors, which detect fabric thickness and adjust tension accordingly, ensuring precision in stitching. Additionally, many machines come with built-in software that allows users to create custom designs and applications, making them invaluable for both mass production and bespoke tailoring.

Impact on the Industry

The introduction of automatic sewing has had profound implications for the fashion and garment industries. Firstly, it has dramatically increased production capabilities, allowing companies to meet growing consumer demands for fast fashion. This efficiency means that garments can be produced in larger quantities and at a lower cost, ultimately benefiting both manufacturers and consumers.

Moreover, automatic sewing machines have helped improve quality control. Automated processes reduce the likelihood of human error, leading to more consistent stitching quality and fewer defects. This consistency is crucial in maintaining the reputation of brands, particularly in a market where competition is fierce.

automatic machine sewing

Challenges and Considerations

Despite its advantages, the rise of automatic machine sewing has not been without challenges. One of the primary concerns is the impact on jobs. As machines take over repetitive tasks, the demand for manual labor in certain aspects of garment production has diminished. This shift raises questions about job displacement and the need for retraining workers in a changing industry landscape.

Another consideration is the environmental impact of increased production. The fast fashion model, fueled by automatic sewing technology, contributes to overproduction and, consequently, significant waste. The textile industry is one of the largest polluters globally, and brands are now facing increasing pressure to adopt sustainable practices.

The Future of Automatic Machine Sewing

Looking ahead, the future of automatic machine sewing seems promising. As technology continues to advance, we can expect even more innovative solutions that combine automation with environmentally friendly practices. The integration of artificial intelligence and machine learning could lead to machines that not only sew but also analyze patterns, predict trends, and optimize resource use.

Furthermore, the rise of customization and personalization in fashion will likely push the limits of automatic sewing technology. Consumers increasingly seek unique garments that reflect their personal style, and automatic sewing machines will need to adapt to fulfill these desires without sacrificing efficiency.

Conclusion

Automatic machine sewing has undoubtedly reshaped the garment industry, enhancing productivity and quality while posing challenges that must be addressed. As technology continues to advance, it holds the potential to further revolutionize the way garments are produced. Balancing efficiency with sustainability will be crucial in ensuring that the benefits of automatic sewing do not come at the expense of the environment or the workforce. The future of automatic machine sewing is not just about stitching fabrics; it’s about creating a harmonious relationship between technology, craftsmanship, and responsibility.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025