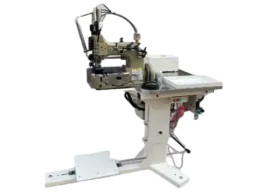

Efficient and Reliable Automatic Bag Sealing Machine for Packaging Solutions

The Importance of Automatic Bag Closer Machines in Modern Manufacturing

In the fast-paced world of manufacturing and packaging, efficiency is key to maintaining a competitive edge. One of the critical components in the packaging process is the bag closer machine, particularly the automatic bag closer machine. These machines have revolutionized how products are packaged, stored, and transported, providing significant benefits to industries ranging from food production to agricultural products.

Automatic bag closer machines are designed to seal bags securely and efficiently, ensuring that the contents remain fresh and protected from contamination. The primary function of these machines is to apply a closing mechanism that can include stitching, heat sealing, or gluing, depending on the type of bag and the material being packaged. This automation not only speeds up the sealing process but also reduces the likelihood of human error, which can lead to costly product waste and potential safety issues.

One of the most significant advantages of using automatic bag closer machines is the enhancement of production speed. Unlike manual closing methods, which can be time-consuming and labor-intensive, these machines can process hundreds or thousands of bags per hour. This increased speed is particularly essential in high-volume production environments where time is money. Manufacturers can meet tight deadlines and fulfill large orders without compromising on quality.

Additionally, these machines contribute to cost savings. By automating the bag closing process, companies can reduce their reliance on manual labor, thereby minimizing labor costs. Furthermore, the consistency and reliability of automatic machines reduce the costs associated with product returns or spoilage due to inadequate sealing. High-quality sealing also leads to improved product shelf life, which is crucial for perishable goods.

automatic bag closer machine

Moreover, advancements in technology have led to the development of highly versatile automatic bag closer machines that can handle various bag sizes, shapes, and materials. This flexibility allows manufacturers to switch between different products with minimal downtime, making it easier to adapt to changing market demands. Features such as programmable settings and user-friendly interfaces facilitate quick adjustments, enabling manufacturers to optimize their production lines efficiently.

In addition to efficiency and cost-effectiveness, automatic bag closer machines also enhance workplace safety. Automated processes minimize the need for employees to be in close contact with heavy machinery or potentially hazardous materials. By streamlining the bag closing process, businesses can create a safer working environment and reduce the risk of workplace injuries.

Sustainability has also become a priority in contemporary manufacturing. With the increasing emphasis on eco-friendly practices, manufacturers are considering how their packaging affects the environment. Automatic bag closer machines can be integrated with sustainable materials and methods, promoting a greener packaging solution. Many modern machines utilize recyclable materials and energy-efficient technologies, aligning with global sustainability efforts.

In conclusion, automatic bag closer machines play a vital role in the manufacturing and packaging industry. By improving speed, reducing costs, enhancing safety, and promoting sustainability, these machines contribute to a more efficient and effective production process. As industries continue to evolve and seek ways to improve their operations, the automatic bag closer machine will undoubtedly remain an invaluable asset in packaging solutions.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025