Advanced Sewing Machines for Automotive Interior Design and Customization Solutions for Modern Vehicles

The Role of Sewing Machines in Automotive Interiors

In the realm of automotive manufacturing, the importance of aesthetics and functionality in vehicle interiors cannot be overstated. As consumers increasingly demand luxurious and comfortable experiences, the role of sewing machines in crafting automotive interiors has become critical. These machines have evolved significantly over the years, adapting to the unique needs of the automotive industry and enhancing the quality and appeal of automobile interiors.

Evolution of Automotive Sewing Machines

Historically, sewing machines used in automotive manufacturing were straightforward, primarily designed for durable stitching that could withstand wear and tear. However, as automotive design has trended towards an emphasis on style and comfort, the machines have evolved to meet these new demands. Modern automotive sewing machines now feature advanced technology, allowing for intricate designs, patterns, and customization. From stitching leather upholstery to sewing together complex airbag fabrics, these machines are essential for achieving the desired aesthetic qualities and safety standards in cars.

Types of Sewing Machines in Automotive Manufacturing

Sewing machines designed for the automotive industry differ in their specifications and functionalities. Some of the most commonly used types include

1. Walking Foot Machines These machines are perfect for sewing thick materials like leather and heavy fabrics, providing stability and even feeding of the material. They are widely used for stitching seat covers and other components requiring durability.

2. Computerized Sewing Machines With the integration of computerized technology, these machines allow for precision stitching and complex embroidery designs. They enable manufacturers to produce customized interiors that cater to specific consumer preferences, enhancing the appeal of a vehicle brand.

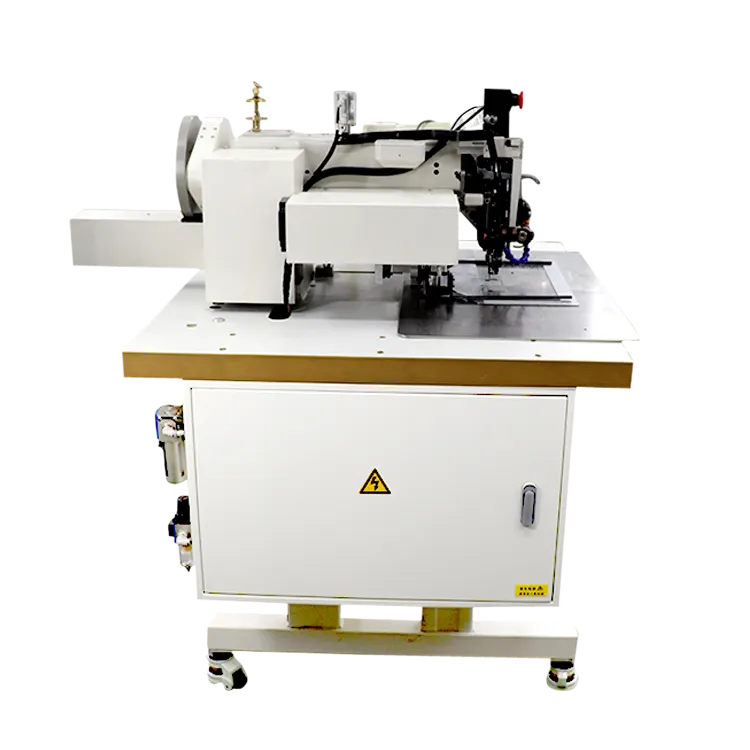

automotive interior sewing machine

3. Overlock Machines These are crucial for finishing seams and preventing fraying on fabric edges. They are often used when sewing lightweight materials, providing a clean finish that maintains the quality of the interior look.

4. Flatbed and Cylinder Bed Machines Ideal for various sewing applications, these machines are versatile and can handle a broad spectrum of sewing tasks, from constructing interior panels to assembling complex designs in seats and door trims.

Importance of Quality and Precision

The quality of stitching in automotive interiors not only affects the aesthetics but also has implications for safety and durability. High-quality stitches allow for effective integration of safety features such as airbags, while also ensuring that the upholstery can withstand the rigors of everyday use. Imperfections in sewing can lead to failures in these safety systems, underscoring the importance of precision in every stitch.

Innovations in Automotive Sewing Technology

Technological advancements have brought significant improvements to sewing machines over the years. Features such as automatic thread cutting, programmable stitching patterns, and advanced tension control systems contribute to efficiency and quality in production processes. Additionally, manufacturers increasingly focus on sustainability, leading to the development of sewing machines capable of working with eco-friendly materials and processes, thereby reducing environmental impact.

Conclusion

In summary, sewing machines play a pivotal role in the automotive industry's quest for excellence in vehicle interiors. The evolution of these machines reflects broader trends in consumer demand for high-quality, aesthetically pleasing, and durable vehicles. As technology continues to advance, the capabilities of automotive sewing machines will likely expand even further, enabling manufacturers to create even more innovative and personalized automotive experiences. Ultimately, the sewing machine has transformed from a simple tool into a critical component of automotive design and production, shaping the future of car interiors.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025