Exploring the Benefits and Applications of 2% Needle Lockstitch Technology in Sewing

Understanding the 2% Needle Lockstitch in Sewing Technology

The sewing industry has witnessed remarkable advancements in technology over the years, with a variety of stitching methods developed to enhance efficiency and durability. One such method is the 2% needle lockstitch, a technique that has gained considerable attention for its unique attributes and practical applications in garment manufacturing and other textile productions.

What is a Needle Lockstitch?

To comprehend the significance of the 2% needle lockstitch, it is essential to understand what a needle lockstitch entails. Traditional lockstitching is a widely used method that employs a needle and a bobbin thread to create a strong and secure seam. The needle penetrates the fabric layer, pulling the upper thread through it, which then intertwines with the lower thread from the bobbin. This interlocking mechanism ensures that the fabric pieces remain firmly attached, able to withstand wear and tear.

The term 2% needle lockstitch refers specifically to a variation of this traditional method, where adjustments are made to the tension settings or the stitch configuration to achieve specific results. This slight modification is critical in producing a stitch that not only meets quality standards but also enhances the overall aesthetics and functionality of the finished product.

Advantages of the 2% Needle Lockstitch

One of the primary advantages of the 2% needle lockstitch is its ability to provide greater control over the stitch formation. By adjusting the needle tension and the ratio of the upper to lower threads, manufacturers can achieve a stitch that is both tight and flexible. This flexibility is crucial for fabrics that undergo significant stress during wear, such as stretch fabrics or materials used in activewear.

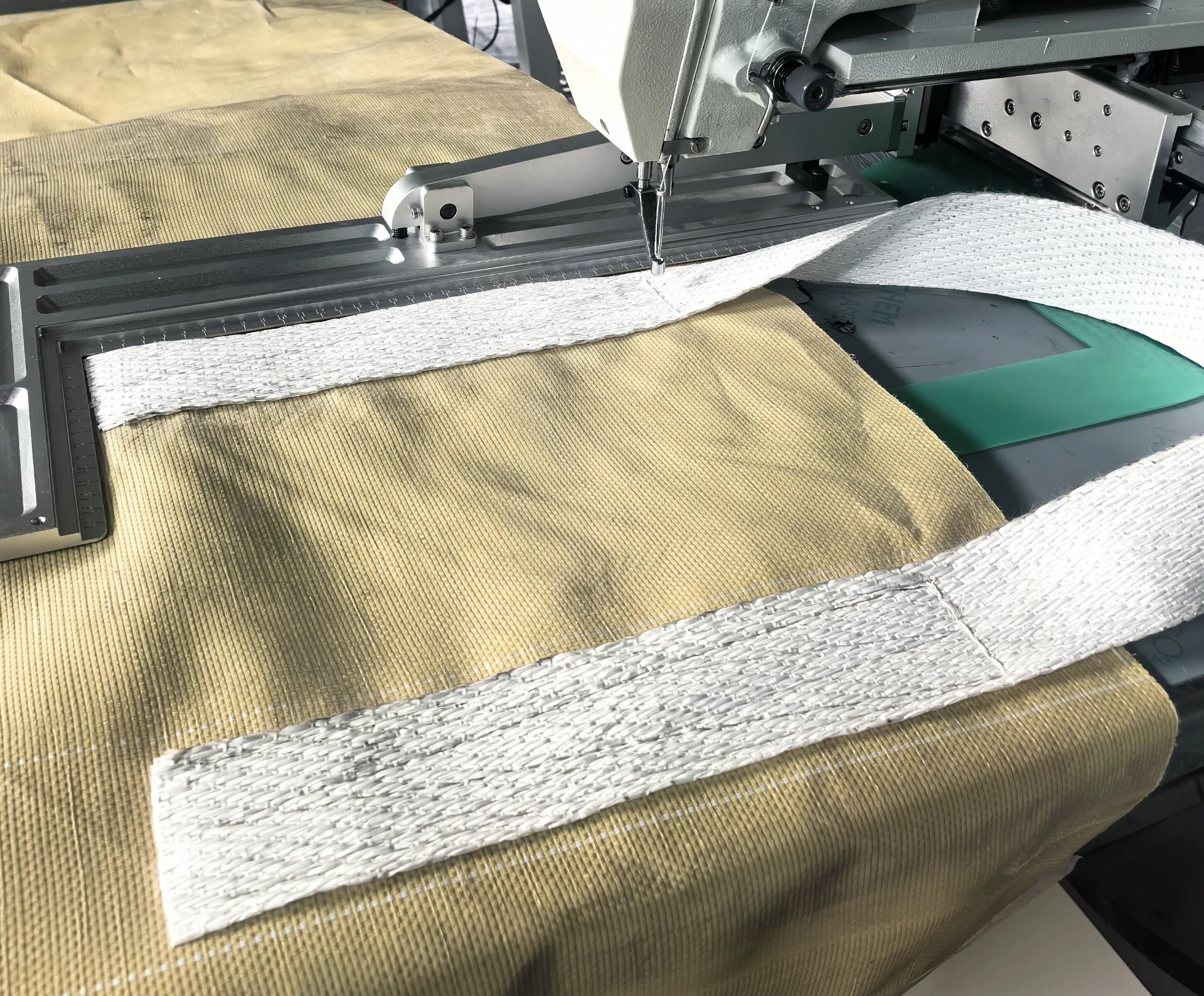

2 needle lockstitch

Moreover, the 2% needle lockstitch can contribute to reducing fabric puckering, a common issue in sewing where the fabric’s surface becomes uneven due to incorrect tension settings. A properly adjusted 2% needle lockstitch allows for a more streamlined appearance, enhancing the visual appeal of the finished garment.

Practical Applications

The 2% needle lockstitch is particularly beneficial in the production of apparel where seams are subjected to regular movement, such as sportswear, swimwear, and fitted garments. Its strength and ability to accommodate stretch without compromising the seam’s integrity make it a popular choice among manufacturers striving for high-quality end products.

In addition to garment manufacturing, this stitch variation is also used in upholstery, automotive interiors, and other industries where durability and aesthetics are paramount. As consumer demands for quality continue to rise, the role of efficient stitching technologies like the 2% needle lockstitch in meeting these demands cannot be understated.

Conclusion

The 2% needle lockstitch exemplifies the innovative spirit that drives the textile industry forward. By refining traditional sewing techniques, manufacturers can enhance the performance and visual appeal of their products. As advancements in sewing technology continue to evolve, it is likely that variations like the 2% needle lockstitch will become increasingly integral to creating garments that not only meet but exceed consumer expectations.

In a world where quality and durability are in constant demand, understanding and mastering techniques like the 2% needle lockstitch will play a vital role in shaping the future of fashion and textile manufacturing. As sewists and manufacturers alike embrace this sophisticated technique, the potential for creating superior products will only continue to grow.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025