Feb . 08, 2025 06:00

Back to list

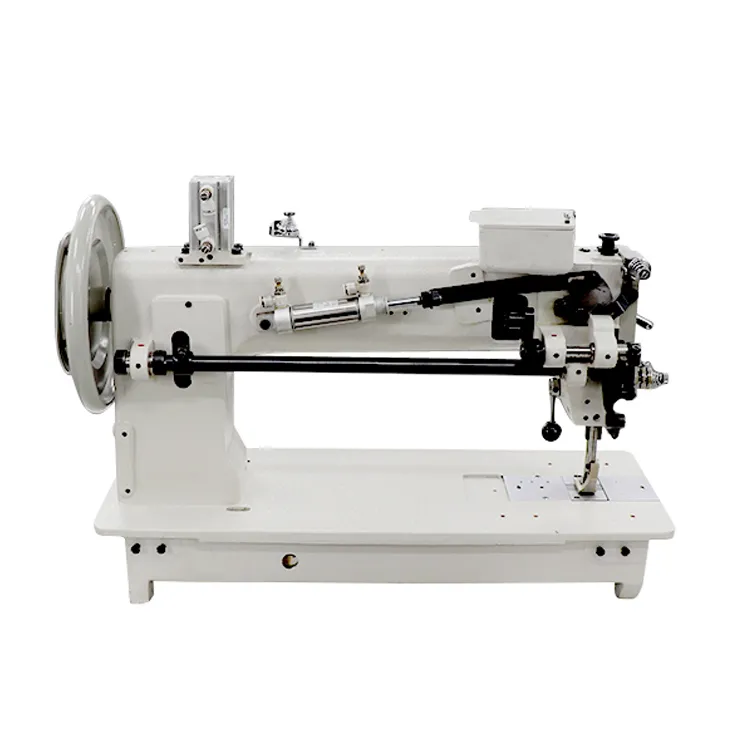

cnc machine sewing

A CNC (Computer Numerical Control) sewing machine signifies a transformative leap in textile manufacturing, blending advanced technology with precision engineering. These cutting-edge machines have emerged as pivotal tools for manufacturers seeking efficiency, precision, and versatility in their operations. Distinct from traditional sewing machines, CNC sewing machines utilize a computerized system to control the needle, feed, and other parameters, ensuring precision and consistency.

The authority of CNC sewing machines in the textile industry is reinforced by their role in enhancing operational efficiency. By drastically reducing the need for skilled manual labor, these machines mitigate the impact of labor shortages and escalating wage pressures. Furthermore, their automated nature minimizes human error, leading to higher throughput and less material wastage. Companies leveraging CNC sewing technology often report significant boosts in productivity and a swift return on investment. Trust in CNC sewing machines is built through the consistent performance they deliver. Manufacturers invest in these technologies for their long-term reliability and capability to deliver repeatable results. The CNC systems are designed to withstand the rigors of mass production environments, ensuring longevity and reduced maintenance costs. Additionally, comprehensive training programs and ongoing support from manufacturers boost confidence in the users, ensuring they can fully capitalize on the machine's capabilities. In the competitive landscape of textile manufacturing, adopting CNC sewing machines is an astute strategic move. They not only elevate the quality and precision of textile products but also enhance the overall efficiency of production processes. As technology continues to evolve, CNC sewing machines are likely to incorporate even more sophisticated features, such as AI-driven design adjustments and predictive maintenance alerts, further cementing their position as indispensable assets in modern manufacturing. In summary, CNC sewing machines represent the synthesis of precision engineering and digital technology, offering manufacturers a substantial edge in quality, efficiency, and creativity. Their ability to meet the demands of diverse industries with unwavering accuracy makes them a cornerstone of contemporary textile manufacturing. For businesses aiming to elevate their production capabilities and product offerings, investing in CNC sewing technology is a decision aligned with future-oriented growth and innovation.

The authority of CNC sewing machines in the textile industry is reinforced by their role in enhancing operational efficiency. By drastically reducing the need for skilled manual labor, these machines mitigate the impact of labor shortages and escalating wage pressures. Furthermore, their automated nature minimizes human error, leading to higher throughput and less material wastage. Companies leveraging CNC sewing technology often report significant boosts in productivity and a swift return on investment. Trust in CNC sewing machines is built through the consistent performance they deliver. Manufacturers invest in these technologies for their long-term reliability and capability to deliver repeatable results. The CNC systems are designed to withstand the rigors of mass production environments, ensuring longevity and reduced maintenance costs. Additionally, comprehensive training programs and ongoing support from manufacturers boost confidence in the users, ensuring they can fully capitalize on the machine's capabilities. In the competitive landscape of textile manufacturing, adopting CNC sewing machines is an astute strategic move. They not only elevate the quality and precision of textile products but also enhance the overall efficiency of production processes. As technology continues to evolve, CNC sewing machines are likely to incorporate even more sophisticated features, such as AI-driven design adjustments and predictive maintenance alerts, further cementing their position as indispensable assets in modern manufacturing. In summary, CNC sewing machines represent the synthesis of precision engineering and digital technology, offering manufacturers a substantial edge in quality, efficiency, and creativity. Their ability to meet the demands of diverse industries with unwavering accuracy makes them a cornerstone of contemporary textile manufacturing. For businesses aiming to elevate their production capabilities and product offerings, investing in CNC sewing technology is a decision aligned with future-oriented growth and innovation.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025