Choosing the Right Upholstery Binding Machine for Your Upholstery Projects

Upholstery Binding Machines An Essential Tool for the Textile Industry

In the fast-paced world of the textile industry, efficiency and quality are paramount. One of the critical aspects of furniture production, vehicle interiors, and various textile applications is the finishing process, which often includes binding. Upholstery binding machines have become essential tools, streamlining the process while enhancing the overall quality of the finished product.

What is an Upholstery Binding Machine?

An upholstery binding machine is a specialized piece of equipment designed to attach binding binding materials to the edges of upholstery fabric. This could include a variety of fabrics used in sofas, chairs, vehicle seats, and even bedding. The binding not only adds a decorative touch but also provides reinforcement, preventing fraying and extending the life of the upholstery.

Types of Upholstery Binding Machines

Upholstery binding machines come in various forms, tailored to different binding techniques and applications. The most common types include

1. Single Needle Binding Machines These machines use a single needle and are typically used for straightforward binding tasks. They are user-friendly and suitable for small-scale operations.

2. Double Needle Binding Machines These machines have two needles and are designed for more complex binding operations. They allow for greater speed and efficiency, making them ideal for larger production runs.

3. Heavy-Duty Binding Machines Built to handle thick and heavy fabrics, these machines are essential for industries that work with durable materials, such as automotive upholstery or outdoor furniture.

4. Automatic Binding Machines These state-of-the-art machines automate the binding process, significantly increasing production speed. They are equipped with advanced features such as programmable settings and sensors to ensure precision and consistency.

The Importance of Upholstery Binding Machines

1. Enhanced Aesthetics The binding process adds a polished look to upholstered furniture. A well-bound edge can elevate the appearance of a product, making it more appealing to consumers.

2. Durability Binding reinforces the edges of upholstery, preventing fraying and extending the longevity of the fabric. This is particularly important in high-use items like furniture and automotive interiors.

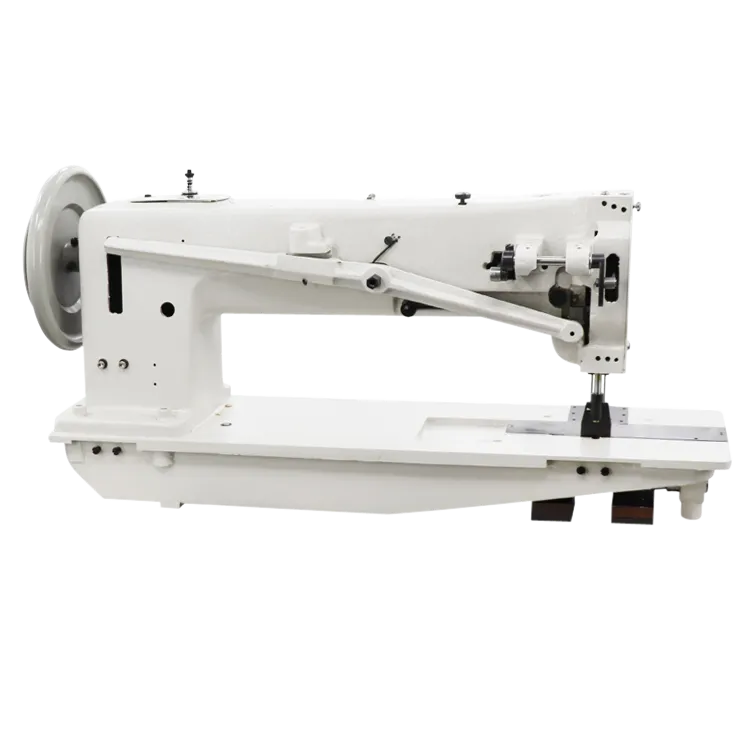

upholstery binding machine

3. Efficiency Modern upholstery binding machines are designed for speed and accuracy. They reduce the time spent on manual binding processes, allowing manufacturers to focus on other aspects of production.

4. Versatility Upholstery binding machines can accommodate a wide range of materials and binding types, making them suitable for various applications beyond furniture, including automotive and marine upholstery.

Technological Advancements in Upholstery Binding

The upholstery binding machine industry has seen significant advancements in technology. Many of today’s machines incorporate computerized controls that allow for precise adjustments and programmable sewing patterns. This level of automation leads to higher consistency and quality in finished products. Additionally, many new machines come equipped with features like automatic thread tension adjustment and integrated cutting systems, further enhancing efficiency.

Choosing the Right Upholstery Binding Machine

When selecting an upholstery binding machine, several factors must be considered

1. Type of Materials Understand the types of fabrics you will be working with. Heavier materials require heavy-duty machines, while lighter fabrics can use standard models.

2. Production Volume For small-scale operations, a single needle machine may suffice. However, larger businesses should consider automatic or double needle machines to keep up with demand.

3. Budget While higher-end machines offer more features, it’s essential to find a balance between cost and capability. Investing in a quality machine can pay off in the long run through increased efficiency and reduced fabric waste.

4. Additional Features Look for machines that offer easy maintenance, part availability, and support services to ensure smooth operation.

Conclusion

Upholstery binding machines are indispensable in the textile industry, providing both functional and aesthetic benefits. With advancements in technology and a variety of machine types available, manufacturers can choose the right equipment to meet their specific needs. As the demand for high-quality upholstery continues to grow, these machines will remain vital in ensuring that products are not only functional but also visually appealing and durable. Investing in a quality upholstery binding machine is a strategic move that promises to enhance productivity and product quality in the competitive textile market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025