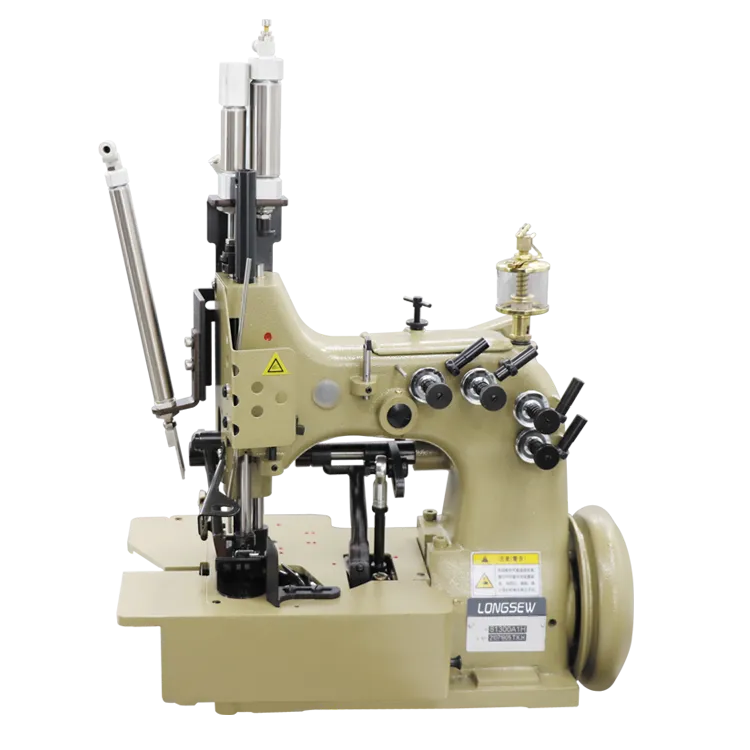

single needle lock stitch machine

The Versatility and Efficiency of Single Needle Lock Stitch Machines

In the realm of industrial sewing, the single needle lock stitch machine stands out as one of the most essential and widely used devices. With its simple yet effective design, this machine is capable of producing high-quality stitches that are crucial in various sewing applications, from garment manufacturing to upholstery. Understanding the inner workings, advantages, and applications of single needle lock stitch machines can help businesses make informed decisions about their sewing processes.

At its core, the single needle lock stitch machine operates on a straightforward mechanism. It uses a single needle to create stitches by interlocking the upper thread with a lower thread, which is typically provided by a bobbin. This simple design allows for efficiency in stitching, making it suitable for both lightweight and medium-weight fabrics. The machine can produce a variety of stitch types, including straight stitches and, in some instances, zigzag or decorative stitches, allowing for flexibility in design.

One of the primary advantages of single needle lock stitch machines is their ability to create strong and durable seams. The interlocking of threads results in a tight stitch that can withstand the stresses of wear and tear, making it ideal for clothing, accessories, and home textiles. This aspect is particularly important in the fashion industry, where the quality of stitching can significantly impact the overall look and longevity of a product.

Moreover, single needle lock stitch machines are known for their speed and efficiency. Modern machines can achieve stitching speeds of up to 5,000 stitches per minute, drastically reducing the time required to complete sewing projects. This speed is essential for high-volume production environments, where meeting deadlines and maintaining productivity are critical. Additionally, the straightforward operation of these machines allows for quick training of operators, enabling companies to adapt to workforce changes with minimal downtime.

single needle lock stitch machine

The versatility of single needle lock stitch machines extends beyond mere stitching capabilities. Many models come equipped with features such as adjustable stitch length, automatic thread cutting, and programmable sewing patterns, making them adaptable to a variety of projects. This adaptability makes them suitable not only for garment manufacturing but also for industries such as automotive upholstery, leather goods, and even technical textiles.

One of the challenges faced by manufacturers utilizing single needle lock stitch machines is the potential for thread breakage or tension issues. However, advancements in thread technology and machine engineering have mitigated many of these concerns. High-quality threads designed for specific fabrics can enhance the performance of the machine, resulting in fewer interruptions and better stitch quality. Additionally, regular maintenance of the machine, including lubrication and cleaning, is vital to ensure optimal performance.

Environmental considerations are also increasingly influencing the choice of sewing machines in the industry. Many manufacturers are developing eco-friendly sewing solutions by utilizing energy-efficient motors and sustainable materials in their machines. This trend aligns with the growing demand for sustainable practices in manufacturing, ensuring that companies can meet consumer expectations while minimizing their environmental footprint.

In conclusion, the single needle lock stitch machine remains a cornerstone of the sewing industry due to its efficiency, versatility, and quality of stitching. As technology continues to evolve, these machines are adapting to meet the changing needs of manufacturers and consumers alike. For businesses looking to optimize their sewing processes, investing in high-quality single needle lock stitch machines is a smart choice that promises long-term benefits in productivity and quality. Whether for small-scale production or large manufacturing operations, this machine is an invaluable asset in the world of textile production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025