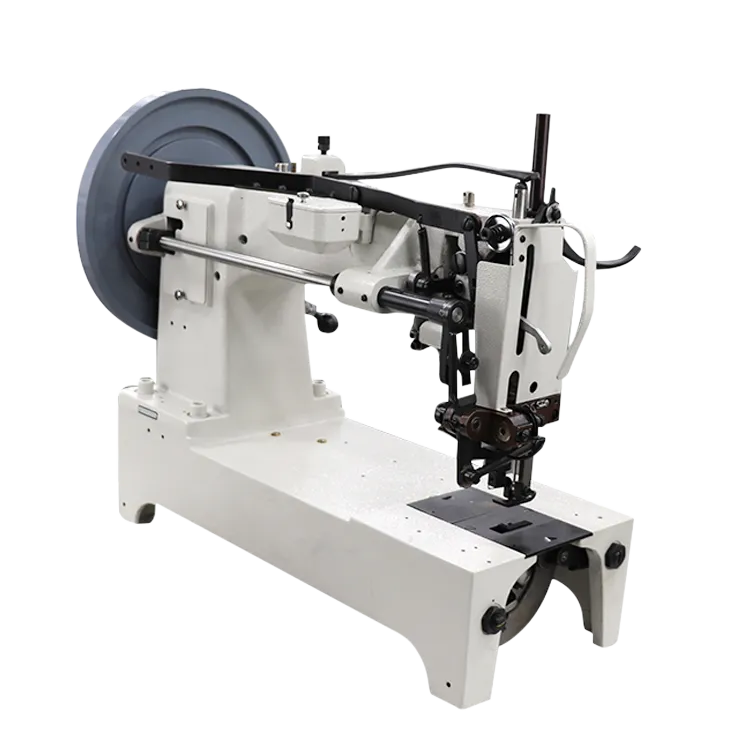

single needle edge cutter machine

The Evolution and Importance of Single Needle Edge Cutter Machines

In the ever-evolving landscape of industrial machinery, the single needle edge cutter machine has carved out a niche for itself in the textile and leather industries. This specialized equipment plays a crucial role in enhancing the quality and efficiency of the cutting process, making it indispensable for manufacturers aiming for precision and excellence in their products.

The Mechanism Behind Single Needle Edge Cutter Machines

At its core, a single needle edge cutter machine operates with a straightforward yet effective mechanism. It employs a single needle that moves up and down to cut through various materials such as fabric, leather, and synthetic composites. The design allows for fine control over the cutting depth and angle, making it a favorite choice for detailed work. Unlike traditional multi-needle machines, the single needle offers superior precision, reducing the risk of uneven edges and waste material.

One of the significant advantages of a single needle edge cutter machine is its ability to handle delicate materials. In industries where intricate designs are critical, such as high-end fashion or bespoke leather goods, the precision cutting provided by this machine is essential. It minimizes the chance of fraying edges, which can ruin the overall aesthetic of a product. The machine's versatility also allows it to be used for various applications, from cutting simple patterns to complex shapes needed for detailed craftsmanship.

Advantages Over Traditional Cutting Methods

The transition from manual cutting methods to machine-operated processes has transformed the efficiency of production lines. Traditional cutting methods often require a skilled artisan to achieve acceptable results, which can be time-consuming and subject to human error. By incorporating a single needle edge cutter machine, manufacturers can significantly speed up the cutting process while maintaining accuracy.

One important advantage is the reduction of labor costs. With machines taking over the responsibilities of multiple manual workers, businesses can allocate their human resources to other essential tasks that require creativity and intricate attention to detail. This shift not only leads to cost savings but also allows for a better utilization of skills within the workforce.

single needle edge cutter machine

Application Across Industries

The single needle edge cutter machine is widely used in various sectors, primarily the textile and leather industries. In the garment industry, for instance, it is employed to create garments with perfectly aligned seams and edges, enhancing the finished product's overall quality. For leather manufacturers, this machine is vital for preparing hides and skins, ensuring that the final leather goods are both aesthetically appealing and functional.

Beyond textiles and leather, these machines find application in other industries such as furniture making, automotive upholstery, and even in the creation of soft goods like quilts and curtains. The versatility of the single needle edge cutter machine makes it a go-to choice for manufacturers across different sectors looking to improve their production capabilities.

Advances in Technology

The advent of technology has brought significant improvements to the single needle edge cutter machine. Modern machines now come equipped with computerized controls that allow for programmed cutting patterns, which maximize efficiency and reduce material waste. Additionally, advancements like laser cutting technology and blades that self-sharpen can further enhance performance, ensuring that these machines remain relevant in an increasingly competitive marketplace.

Moreover, the integration of automation has allowed for faster turnaround times and increased productivity. This capability is particularly vital in today’s fast-paced fashion industry, where trends change rapidly, and consumers demand quick delivery times.

Conclusion

The single needle edge cutter machine stands as a testament to the advancements in manufacturing technology, blending precision and efficiency. Its ability to produce high-quality cuts while reducing labor costs makes it an invaluable asset in the textile and leather industries. As manufacturers continue to push the boundaries of what is possible, this machine will undoubtedly remain a crucial component of production lines, ensuring that products not only meet but exceed customer expectations. With continuous innovations on the horizon, the future certainly looks bright for single needle edge cutter machines, leading the way in precision cutting solutions.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025