Exploring the Functionality and Benefits of Shuttle Mechanisms in Sewing Machines

The Importance of Shuttle Mechanisms in Sewing Machines

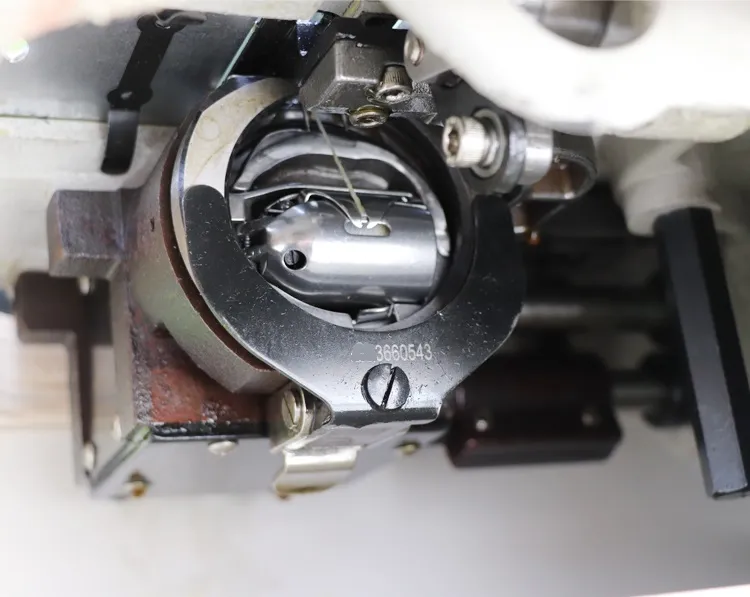

In the world of sewing, the shuttle mechanism plays a pivotal role, especially in traditional sewing machines. It is the heart of the sewing process, responsible for interlocking the upper thread with the bobbin thread to form a sturdy stitch. Understanding how the shuttle functions can greatly enhance a user's sewing experience and equipment maintenance.

What is a Shuttle Mechanism?

The shuttle mechanism is a critical component found in many types of sewing machines. It typically consists of a shuttle hook, a bobbin, and a specially designed casing. The bobbin holds the lower thread, while the shuttle hook is responsible for catching the upper thread as the needle moves up and down. This interaction between the shuttle and threads creates a lock stitch, which is the foundation for durable and aesthetically pleasing seams.

Types of Shuttle Mechanisms

There are various types of shuttle mechanisms, each designed to suit different sewing needs. The most common types include

1. Rotary Shuttles These shuttles rotate in a circular motion, allowing for smooth thread passage and consistent stitching. Rotary shuttles are often found in modern machines, providing faster sewing speeds and improved efficiency.

2. Oscillating Shuttles These shuttles move back and forth in a limited arc, making them simpler in design. Although they are prevalent in older sewing machines, oscillating shuttles can still deliver high-quality stitching and are appreciated for their reliability.

3. Drop-in Shuttles A modern innovation, drop-in shuttles allow users to easily insert the bobbin from the top of the machine. This design simplifies the threading process and makes it more accessible for beginners.

silai machine shuttle

Maintenance of Shuttle Mechanisms

Proper maintenance of the shuttle mechanism is essential for the longevity and performance of a sewing machine. Here are some tips to keep in mind

- Regular Cleaning Dust and lint can accumulate in and around the shuttle area, leading to decreased performance. Regularly clean the area with a small brush or a vacuum attachment to prevent buildup.

- Lubrication Most sewing machines require occasional lubrication to keep the shuttle moving smoothly. Refer to the user manual for specific lubrication points and recommended oils.

- Thread Quality Using high-quality threads can reduce tension and friction within the shuttle mechanism, resulting in smoother operation and fewer breaks.

- Proper Bobbin Loading Incorrectly loaded bobbins can cause threading issues and affect stitch quality. Always ensure that the bobbin is wound evenly and inserted correctly into the shuttle casing.

Conclusion

The shuttle mechanism is an essential feature of sewing machines that allows for the creation of various stitches. By understanding how it works and how to properly maintain it, users can enhance their sewing projects and extend the life of their machines. Whether you are an experienced seamstress or a beginner, appreciating the intricacies of the shuttle mechanism will empower you to achieve better results in your sewing endeavors. So the next time you sit down at your machine, take a moment to consider the vital role that the shuttle plays in your creative process.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025